A pressure-balanced self-aligning electric drill pipe

A balanced electric drill pipe technology, which is applied to drill pipes, drill pipes, and earthwork drilling and mining, can solve the problems of large electrical joints, low reliability, and low transmission efficiency of electric drill pipes, so as to avoid unbalanced load and facilitate maintenance and replacement, the effect of improving reliability and power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is not limited by the following examples, and specific embodiments can be determined according to the technical solutions and actual conditions of the present invention. The present invention will be described below with reference to the accompanying drawings.

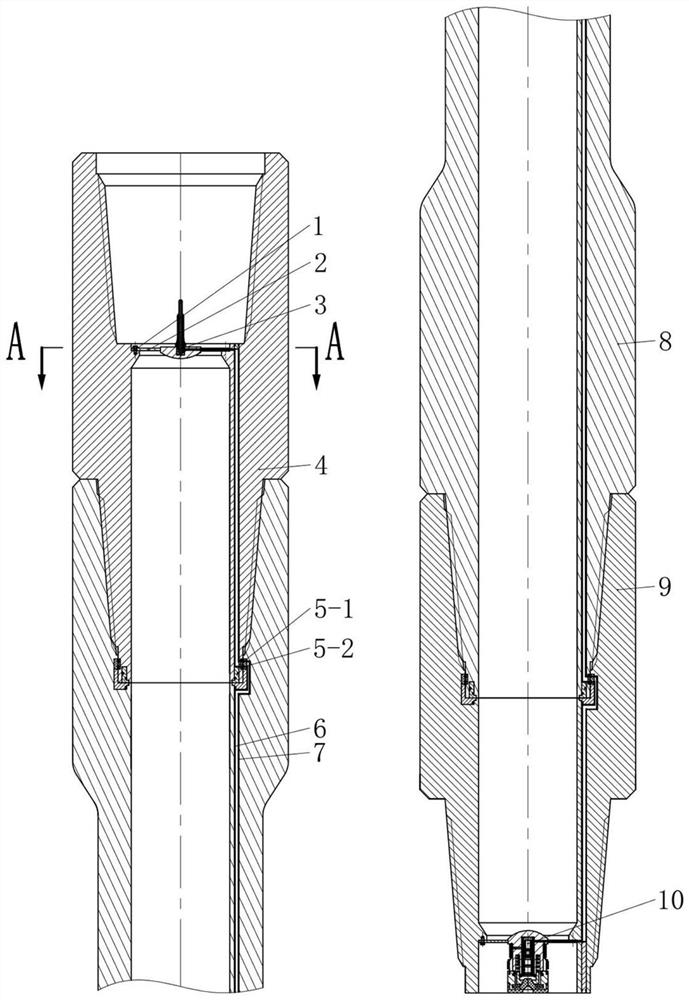

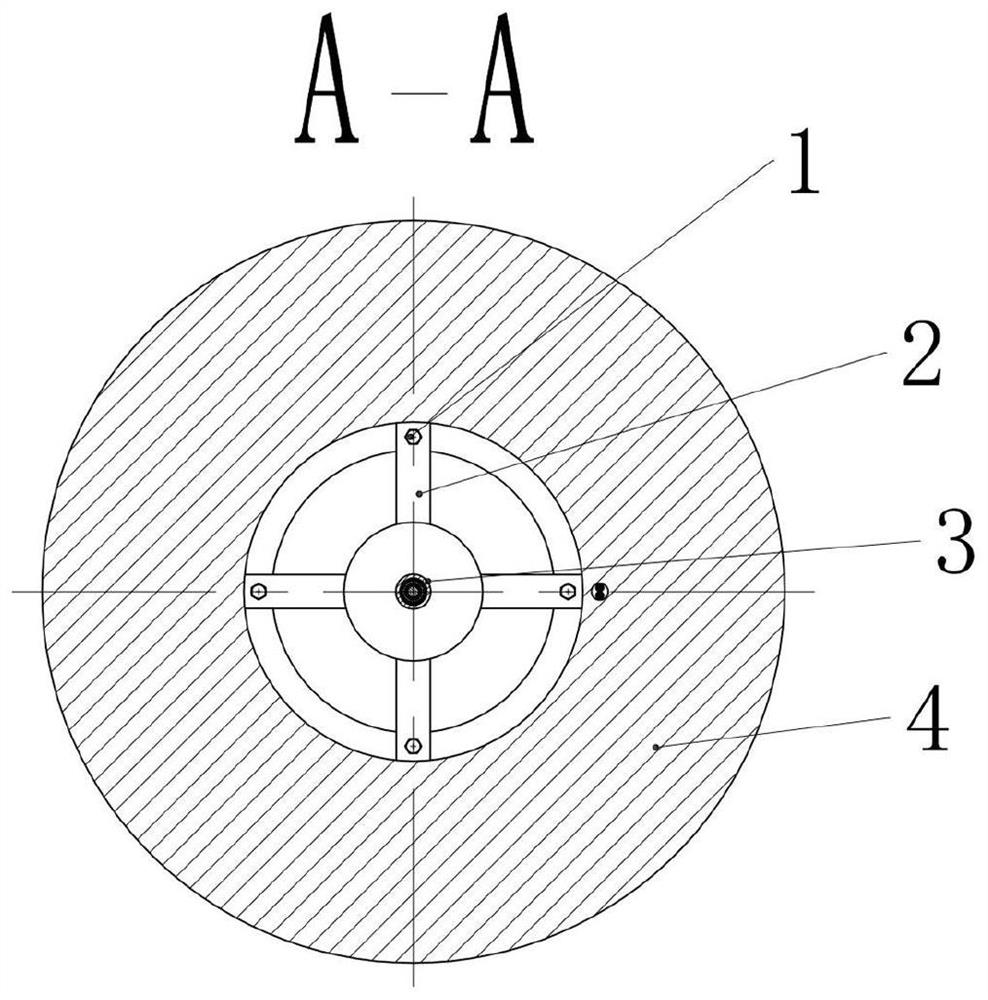

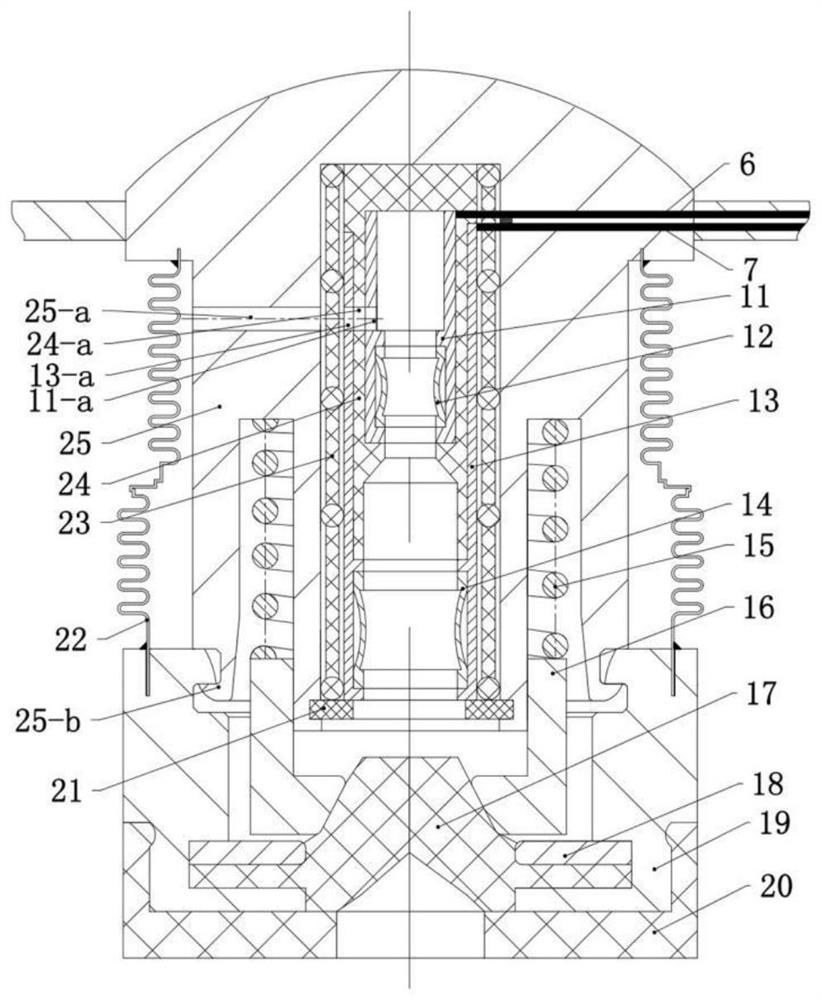

[0020] like figure 1 As shown, a pressure-balanced self-aligning electric drill pipe includes a drill pipe 8, a short pin section 4, a pin assembly 3, a short socket section 9, a socket assembly 10, a screw 1, a support frame 2, and a conductive ring assembly 5 and an insulated cable assembly, characterized in that: the socket assembly 10 includes a conductive device, a pressure balance device, an elastic positioning sleeve 23 and a positioning ring 21; the elastic positioning sleeve 23 is sleeved outside the conductive device; the pin assembly 3 It includes a pin housing 26, a pin insulation layer 27, an outer pin 28 and an inner pin 29; the conductive ring assembly 5 includes a first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com