Environment-friendly automobile exhaust treatment system and treatment method

A technology of automobile exhaust and treatment system, which is applied in the direction of exhaust device, air quality improvement, noise reduction device, etc. It can solve the problem that the three-way catalytic converter does not have the catalytic ability, prolongs the working time of the three-way catalytic converter, and the second carrier is blocked And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

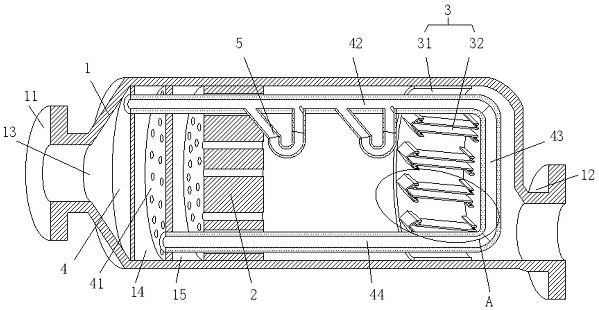

[0041] see Figure 1-2, an environment-friendly automobile exhaust treatment system, comprising a cylinder 1, one end of the cylinder 1 is communicated with an intake pipe 11, the other end of the cylinder 1 is communicated with an outlet pipe 12, and the cylinder 1 is installed with The honeycomb-shaped first carrier 2 is used to catalyze the reduction of automobile exhaust. The first carrier 2 is mainly coated with metals such as platinum and rhodium as a catalyst to catalyze the reduction of nitrogen oxides into nitrogen and oxygen. The cylinder 1 A second carrier 3 is also installed inside for catalytic oxidation of automobile exhaust, the first carrier 2 is close to the intake pipe 11, and the second carrier 3 is close to the outlet pipe 12;

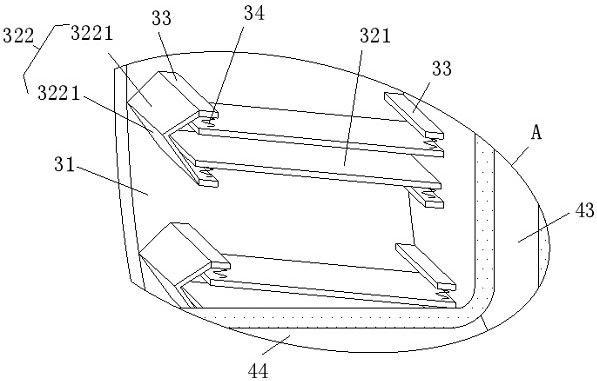

[0042] The second carrier 3 includes a support cylinder 31 installed in the cylinder body 1, and multiple groups of oxidation units 32 are installed in the support cylinder 31, and the oxidation unit 32 includes two oxygen oxidation...

Embodiment 2

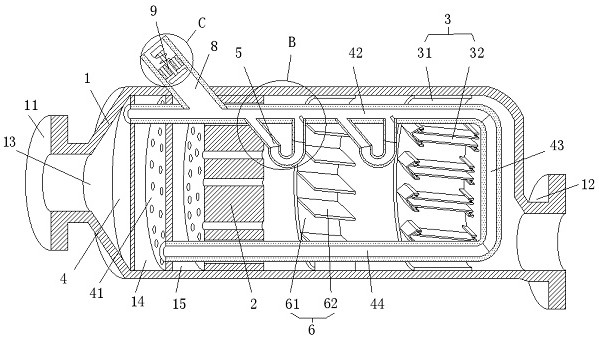

[0047] This embodiment is an explanation made on the basis of Embodiment 1, and on the basis of the accompanying drawings of Embodiment 1, please refer to the accompanying drawings again. Figure 3-4 .

[0048] Specifically, the preheating assembly includes a sealing plate 4 and a deflector plate 41 installed in the cylinder body 1, the sealing plate 4 is located between the intake pipe 11 and the first carrier 2, and is used to block The inner space of cylinder body 1 prevents the exhaust gas from being directly transmitted from the inlet pipe 11 to the outlet pipe 12, the first diversion space 13 is formed between the sealing plate 4 and the inlet pipe 11, and the diversion plate 41 is located in the Between the first carrier 2 and the sealing plate 4, a second flow guiding space 14 is formed between the guide plate 41 and the sealing plate 4, and between the guide plate 41 and the first carrier 2 forming a third diversion space 15;

[0049] The sealing plate 4 is also com...

Embodiment 3

[0061] This embodiment is an improvement made on the basis of Embodiment 1, see Figure 1-4 , the oxidation substrate 321 is arranged obliquely; wherein, the oxidation substrate 321 slopes obliquely downward from an end far away from the air outlet pipe 12 to an end close to the air outlet pipe 12 .

[0062] The inclined setting of the oxidation substrate 321 helps the solid particles on the substrate to shake off and slide to the lower right of the cylinder body 1, and it should be noted that the air outlet pipe 12 is also installed at the lower right end of the cylinder body 1, so that these particles can be discharged from the outlet. Trachea 12 cleared out.

[0063] Further, a flow guide assembly 6 is installed in the cylinder body 1; the flow guide assembly 6 includes a flow guide cylinder 61 installed in the cylinder body 1, and a plurality of flow guide substrates installed in the flow guide cylinder 61 62 , there is a gap between adjacent flow-guiding substrates 62 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com