Method for preparing adsorbing material from astragalus membranaceus waste residues and application of adsorbing material

A technology for adsorbing materials and waste residues, which is applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. The effect of reduced chemical degree and strong water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

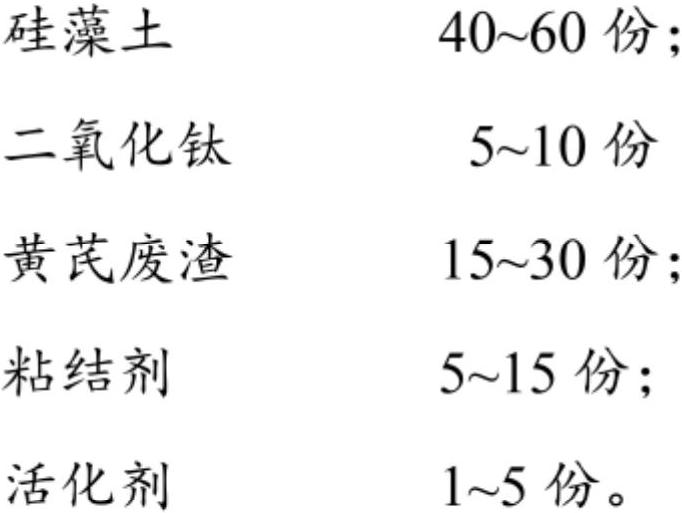

[0037] The astragalus waste residue of this embodiment is used to prepare an adsorption material, which is composed of diatomite, titanium dioxide, waste residue of astragalus, a binder and an activator after being mixed and calcined, and the parts by weight of each component of the raw material are as follows:

[0038]

[0039]

[0040] The activator is a mixed solution of magnesium nitrate and magnesium sulfate, the mass concentration of the magnesium nitrate is 15%, the mass concentration of the magnesium sulfate is 10%, and the molar ratio of the two is 1:1.

[0041] The preparation method of above-mentioned astragalus waste slag preparation adsorption material is as follows:

[0042] (1) The process of pretreatment of astragalus waste residue is as follows: Stir the waste residue of Astragalus membranaceus at 50°C and soak it in potassium hydroxide solution for at least 12 hours; filter, dry the filter residue at 110°C for 1 hour, and pulverize it into a 100-mesh pow...

Embodiment 2

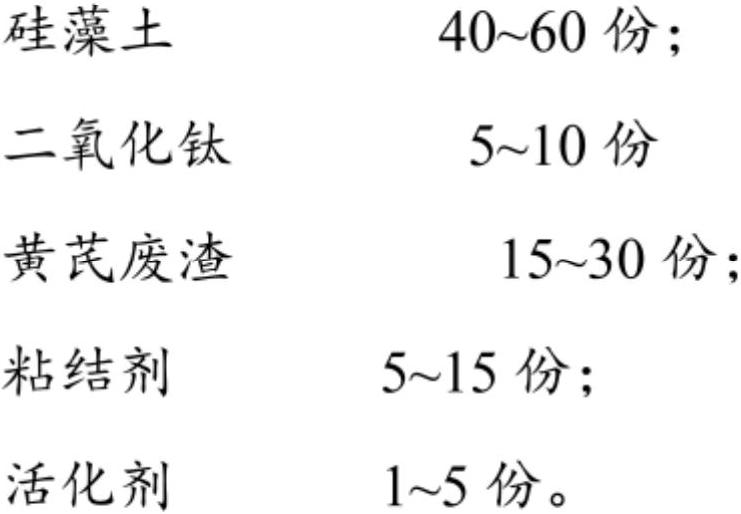

[0052] The astragalus waste residue of this embodiment is used to prepare an adsorption material, which is composed of diatomite, titanium dioxide, waste residue of astragalus, a binder and an activator after being mixed and calcined, and the parts by weight of each component of the raw material are as follows:

[0053]

[0054] The activator is a mixed solution of magnesium nitrate and magnesium sulfate, the mass concentration of the magnesium nitrate is 20%, the mass concentration of the magnesium sulfate is 15%, and the molar ratio of the two is 1:1.

[0055] The preparation method of above-mentioned astragalus waste slag preparation adsorption material is as follows:

[0056] (1) The process of pretreatment of astragalus waste residues is as follows: Stir the waste residues of Astragalus membranaceus at 80°C and soak them in potassium hydroxide solution for at least 12 hours; filter, dry the filter residues at 90°C for 1 hour, and pulverize them into 150-mesh powder;

...

Embodiment 3

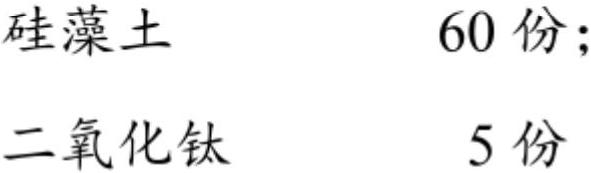

[0066] The astragalus waste residue of this embodiment is used to prepare an adsorption material, which is composed of diatomite, titanium dioxide, waste residue of astragalus, a binder and an activator after being mixed and calcined, and the parts by weight of each component of the raw material are as follows:

[0067]

[0068] The activator is a mixed solution of magnesium nitrate and magnesium sulfate, the mass concentration of the magnesium nitrate is 15%, the mass concentration of the magnesium sulfate is 10%, and the molar ratio of the two is 1:1.

[0069] The preparation method of above-mentioned astragalus waste slag preparation adsorption material is as follows:

[0070] (1) The process of pretreatment of astragalus waste residues is as follows: Stir the waste residues of Astragalus membranaceus at 60°C and soak them in potassium hydroxide solution for at least 12 hours; filter, dry the filter residues at 100°C for 1 hour, and pulverize them into 100-mesh powder;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com