Super high-rise tube well stand tube upside-down mounting construction method

A construction method, technology of inversion method, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the problem of increasing the number of vertical and horizontal transportation of pipelines, the difficulty of vertical connection between upper and lower risers, and increasing Problems such as labor and materials can reduce the number of horizontal and vertical transportation, reduce maintenance costs in the later period, and eliminate poor welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Take a construction project as an example:

[0021] According to the design and distribution of the riser of the project tube well, the construction of the riser is divided into three construction sections: the low area, the middle area and the high area according to the number of building floors. The 33rd floor to the 46th floor of the construction section in the middle area is considered as the construction section in the high area.

[0022] All tube well risers are transported and placed at the corresponding tube wells on the first floor. The construction sequence is the "inverted method" from the high area to the low area. The hoisting equipment mainly includes tools such as electric hoists, manual hoists, and wire ropes.

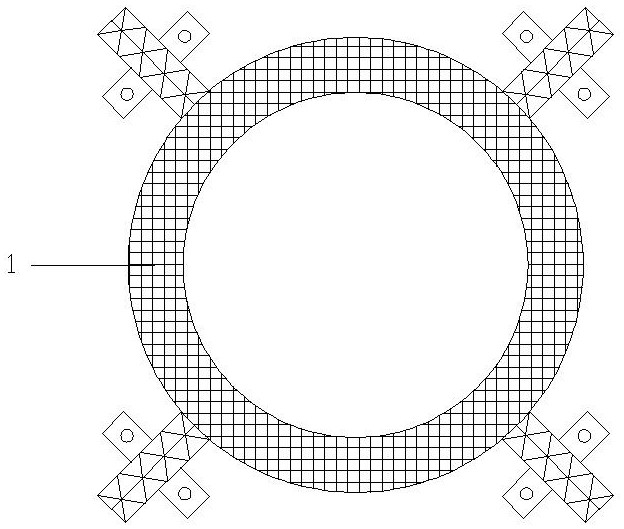

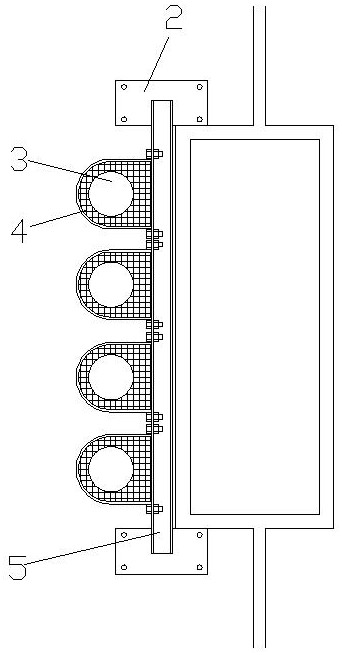

[0023] Such as figure 1 , 2 As shown, a super-high-rise tube well standpipe "flip-chip method" installation and construction method, the specific steps are as follows.

[0024] S100~Based on the number of building floors, it is divided into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com