Variable-frequency pulse formation method based on optimal frequency of lithium ion battery

A lithium-ion battery, frequency conversion pulse technology, applied in secondary batteries, electrochemical generators, secondary battery charging/discharging, etc., can solve problems such as uneven SEI film, to prolong service life, improve cycle stability, Mitigates the effect of internal polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

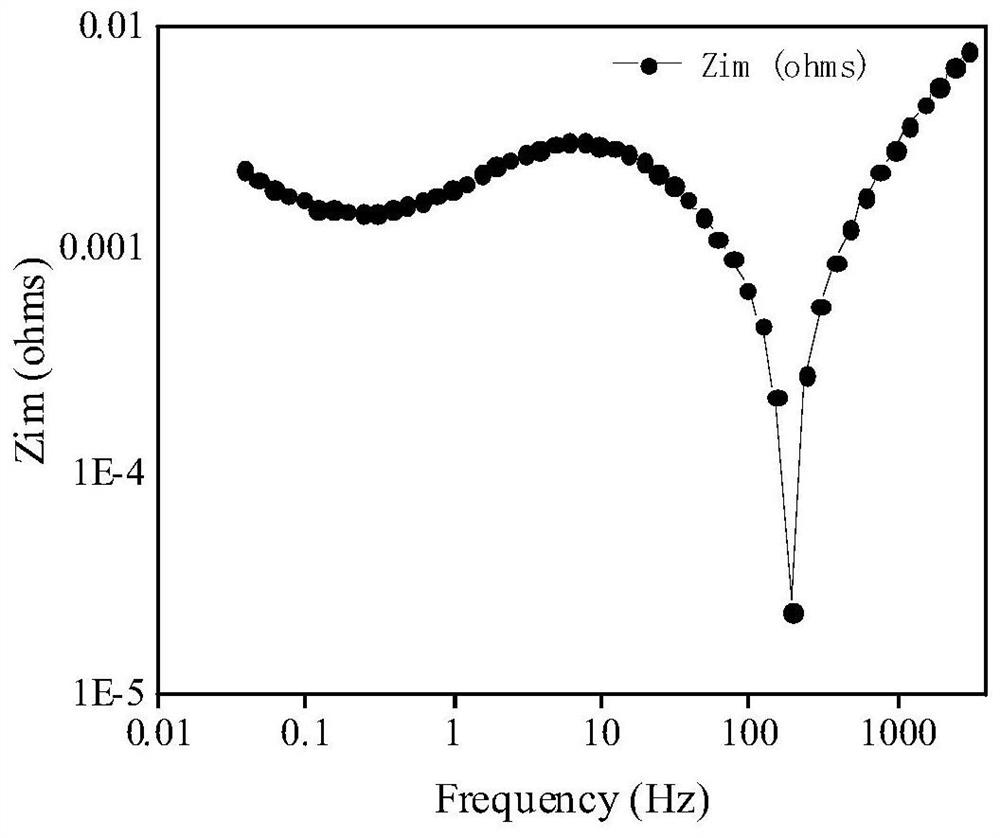

[0022] (1) Measure the electrochemical impedance spectrum (EIS spectrum) of the lithium-ion battery at a specific temperature using an electrochemical workstation in constant current mode. The frequency range of the EIS spectrum is 0.003Hz-3000Hz. The current amplitude is 1000mA;

[0023] (2) Obtain the EIS spectrum of lithium-ion battery by step (1), obtain the Bode diagram of imaginary part impedance changing with frequency (attachment figure 1 ), the imaginary part impedance in the figure is the frequency corresponding to the minimum value as the optimal frequency of the lithium-ion battery;

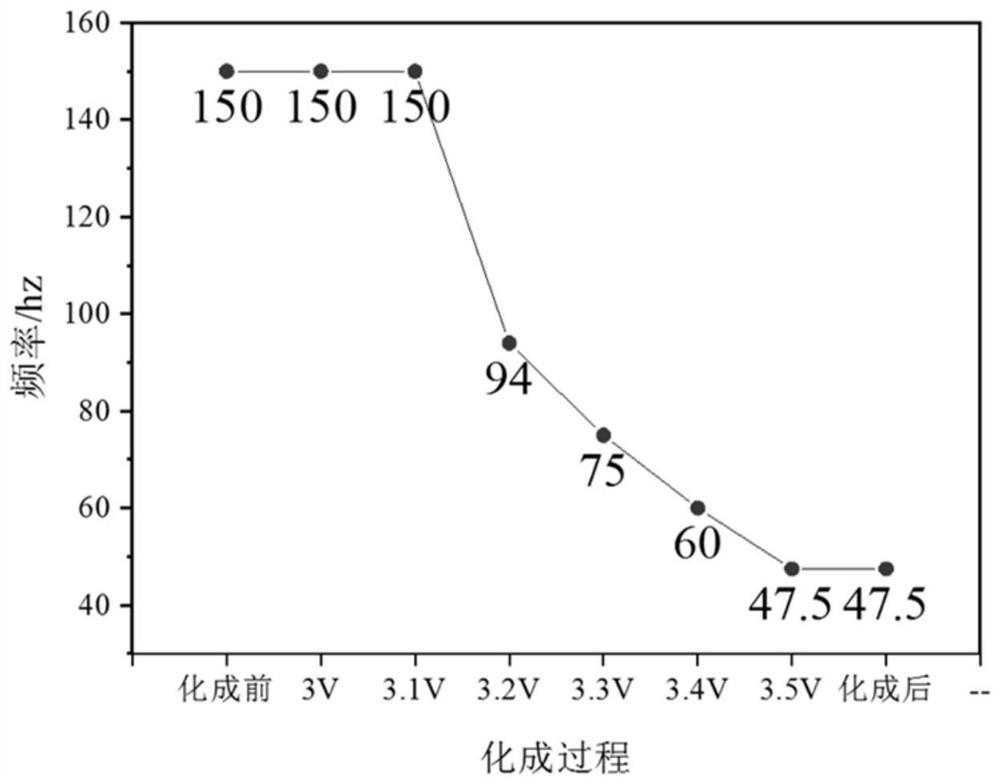

[0024] (3) During the formation process, the optimal frequency of the lithium-ion battery changes with the change of the battery terminal voltage. Therefore, the electrochemical impedance spectroscopy of lithium-ion batteries was tested offline under different battery terminal voltages to obtain the formation voltage-optimum frequency relationship (attached figure 2 );

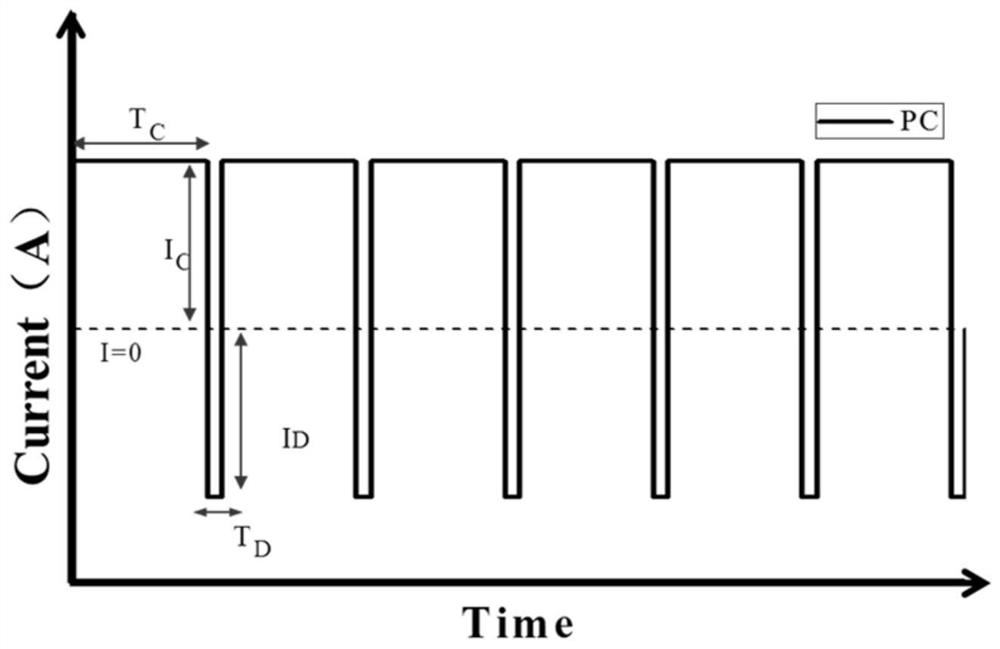

[0025] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com