Die-casting release agent recycling system

A release agent and purification system technology, applied in separation methods, filtration separation, liquid separation, etc., can solve problems such as environmental pollution, release agent quality decline, and mixing, and achieve the effect of reducing production costs and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

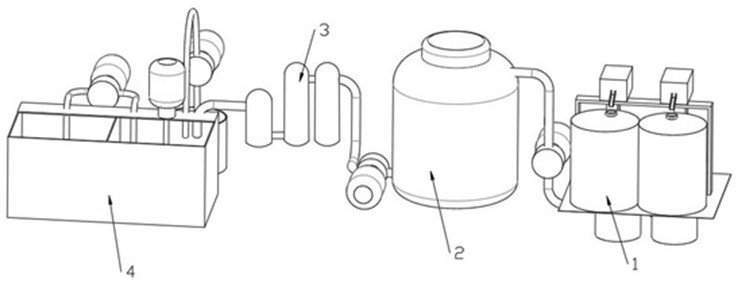

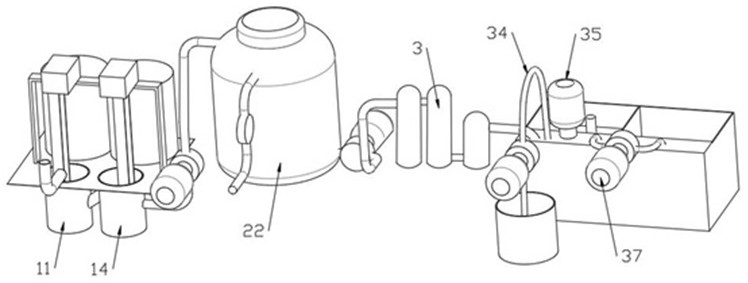

[0029] Such as Figure 1 to Figure 5 A die-casting release agent recycling system shown includes an oil-water separation system 1 , a purification system 2 and a re-concentration blending system 4 .

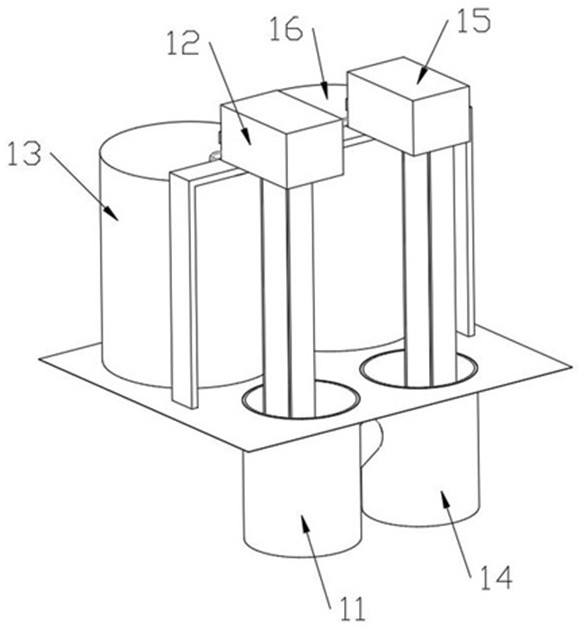

[0030] The oil-water separation system 1 includes a sedimentation tank 11 for collecting waste liquid, a first oil scraper 12, a first oil storage barrel 13, a filtrate barrel 14, a second oil scraper 15 and a second oil storage tank 16, and the used off-type The agent is the waste liquid. After the waste liquid is discharged into the sedimentation tank 11, the chips carried by it settle at the bottom of the sedimentation tank 11, and the oil stains float on the upper end of the release agent; the first oil scraper 12 is a belt type, and its According to the prior art, the first oil scraper 12 scrapes the oil floating in the sedimentation tank 11 into the first oil stora...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap