Coating process of antistatic PET (polyethylene terephthalate) film with wear-resistant structure

A thin-film coating and anti-static technology, which is applied to devices, coatings, special surfaces, etc. that apply liquid to the surface. Accuracy, improving economic efficiency, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

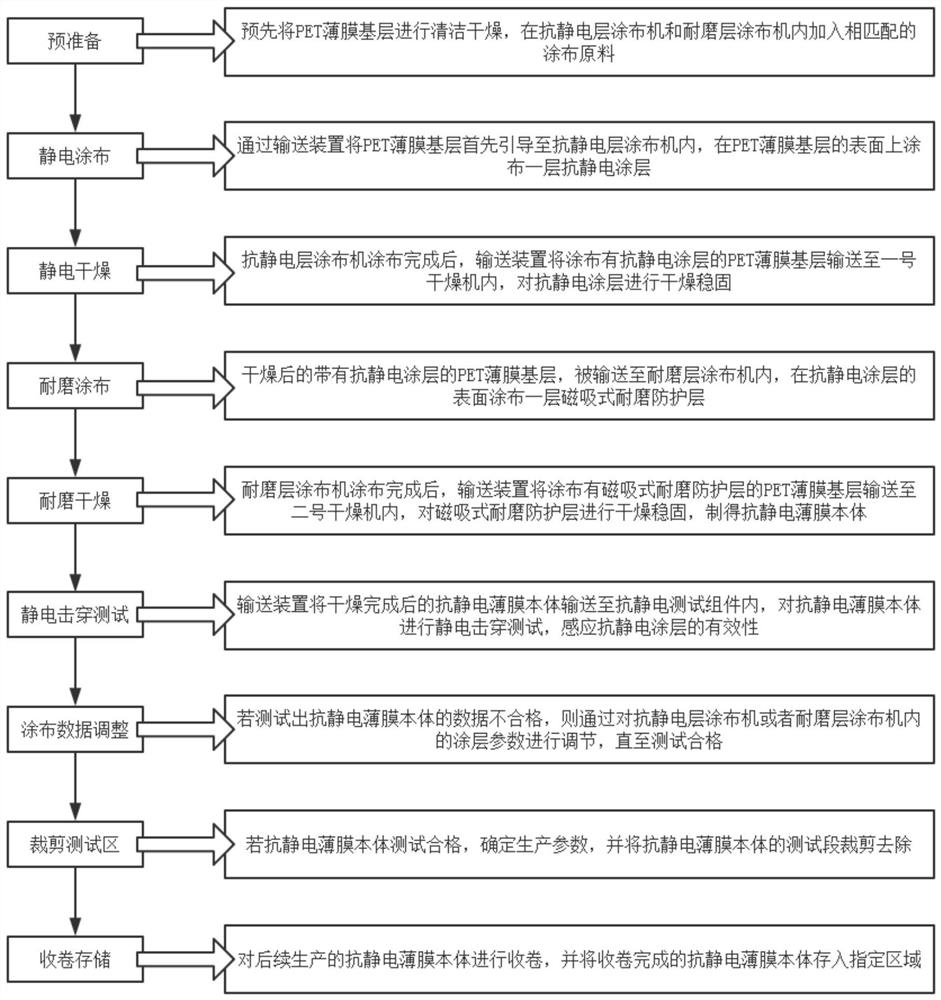

[0055] see Figure 1-10 , a kind of antistatic type PET film coating process with wear-resistant structure, comprises the steps:

[0056] S1. Pre-preparation: clean and dry the PET film base layer 10 in advance, and add matching coating materials into the antistatic layer coater 1 and wear-resistant layer coater 3;

[0057] S2. Electrostatic coating: the PET film base layer 10 is first guided into the antistatic layer coating machine 1 by a conveying device, and one layer of antistatic coating 11 is coated on the surface of the PET film base layer 10;

[0058] S3. Electrostatic drying: After the antistatic layer coating machine 1 is coated, the conveying device transports the PET film base layer 10 coated with the antistatic coating 11 to the No. 1 dryer 2, and the antistatic coating 11 is dried and stabilized ;

[0059] S4. Wear-resistant coating: the dried PET film base layer 10 with antistatic coating 11 is transported to the wear-resistant layer coating machine 3, and a ...

Embodiment 2

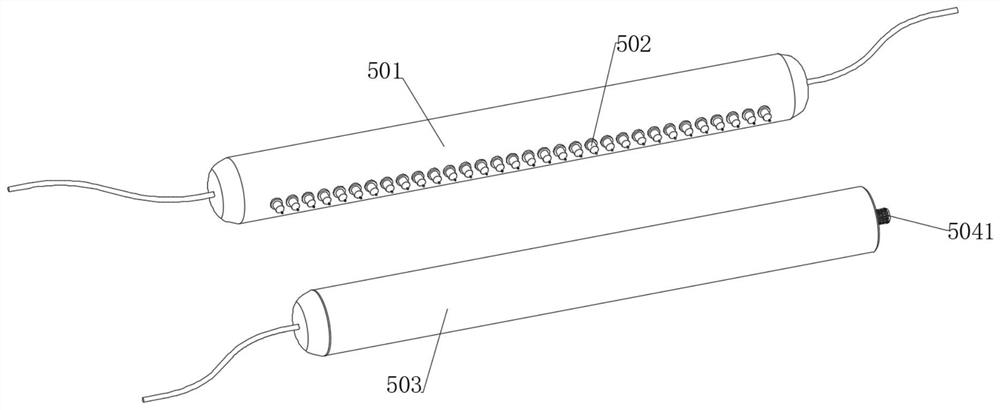

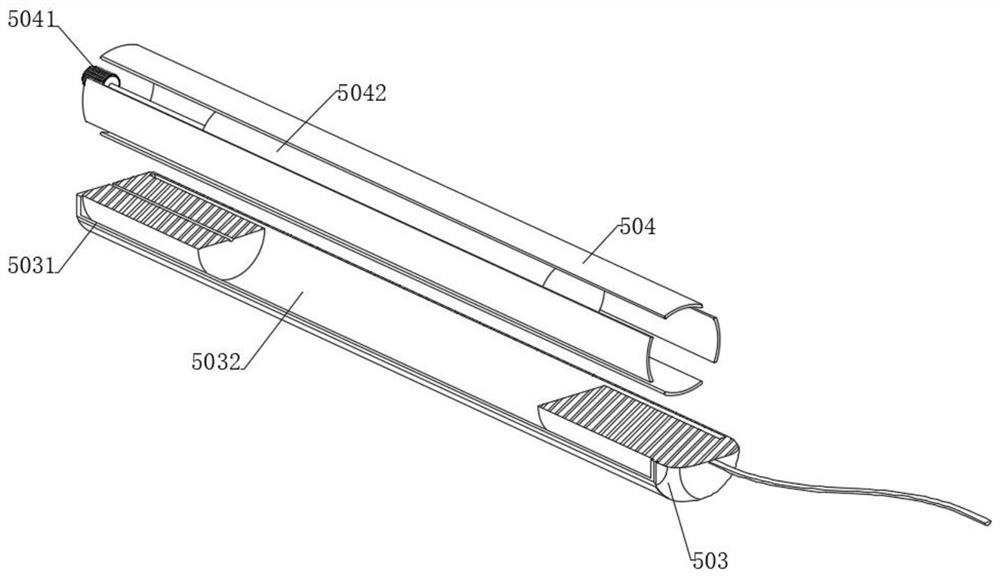

[0069] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 2 , the antistatic test assembly 5 includes a static emission cylinder 501, the antistatic film body 20 is provided with a static emission cylinder 501 near the side of the PET film base layer 10, and the side of the antistatic film body 20 away from the PET film base layer 10 is provided with a breakdown induction cylinder 503, the side of the static emission tube 501 close to the antistatic film body 20 is fixedly connected with a plurality of voltage scattering heads 502, and the side of the breakdown induction tube 503 close to the antistatic film body 20 is provided with a voltage induction tube that matches the breakdown induction tube 503....

Embodiment 3

[0074] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to Figure 6 and Figure 7 The magnetic wear-resistant protective layer 12 includes a plurality of elastic struts 1201 distributed in an array, the lower ends of the plurality of elastic struts 1201 are fixedly connected with the antistatic coating 11 , and the upper ends of the elastic struts 1201 are fixedly connected with the elastic struts 1201 . When the magnetic connection ball 1202 is in contact with the outside to generate friction, the magnetic connection ball 1202 changes the surface-line contact to the surface-point contact, effectively reducing the generation of friction, and through the action of the elastic support 1201, effectively reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com