Water-swelling rubber flexible temporary plugging particle and preparation method thereof

A water-swellable rubber and flexible technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of oil increase and water cut in oil wells, etc., and achieve the characteristics of small loss of rubber material, easy flowback, and excellent water absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, the following steps are used to prepare water-swellable rubber flexible temporary plugging particles:

[0033] (1) Dissolve 10 g of acrylamide, 4 g of bentonite and 1.8 g of diacetone acrylamide in 50 g of deionized water successively using ultrasound;

[0034] (2) Add the aqueous solution prepared in step (1) to 16.63 g of concentrated natural rubber latex, stir evenly, seal it, and place it in a constant temperature water bath at 45°C for aging for 2 hours;

[0035] (3) Add 0.035g potassium persulfate, 0.035g sodium bisulfite, 0.06g N’N-methylenebisacrylamide, stir well, seal and react at 45°C for 4.5h to form a gel;

[0036] (4) Use scissors to cut into pieces of about 1cm×1cm×1cm, place them in an oven at 90°C for drying, and crush the dried pieces with a pulverizer.

Embodiment 2

[0038] In this example, the following steps are used to prepare water-swellable rubber flexible temporary plugging particles:

[0039] (1) Dissolve 10g of acrylamide, 4g of bentonite and 1.8g of sodium p-styrenesulfonate hydrate in 50g of deionized water successively using ultrasound;

[0040] (2) Add the aqueous solution prepared in step (1) to 16.63 g of concentrated natural rubber latex, stir evenly, seal it, and place it in a constant temperature water bath at 45°C for aging for 2 hours;

[0041] (3) Add 0.035g potassium persulfate, 0.035g sodium bisulfite, 0.06g N’N-methylenebisacrylamide, stir well, seal and react at 45°C for 4.5h to form a gel;

[0042] (4) Use scissors to cut into pieces of about 1cm×1cm×1cm, place them in an oven at 90°C for drying, and crush the dried pieces with a pulverizer.

Embodiment 3

[0044] In this example, the following steps are used to prepare water-swellable rubber flexible temporary plugging particles:

[0045] (1) Dissolve 10 g of acrylamide, 4 g of bentonite and 1.8 g of diacetone acrylamide in 50 g of deionized water successively using ultrasound;

[0046](2) Add it to 16.63g of concentrated natural rubber latex, stir evenly, seal it, and place it in a constant temperature water bath at 45°C for aging for 2 hours;

[0047] (3) Add 0.035g of ammonium persulfate, 0.035g of sodium thiosulfate, and 0.06g of N’N-methylenebisacrylamide, stir well, seal and react at 45°C for 4.5h to form a gel;

[0048] (4) Use scissors to cut into pieces of about 1cm×1cm×1cm, place them in an oven at 90°C for drying, and crush the dried pieces with a pulverizer.

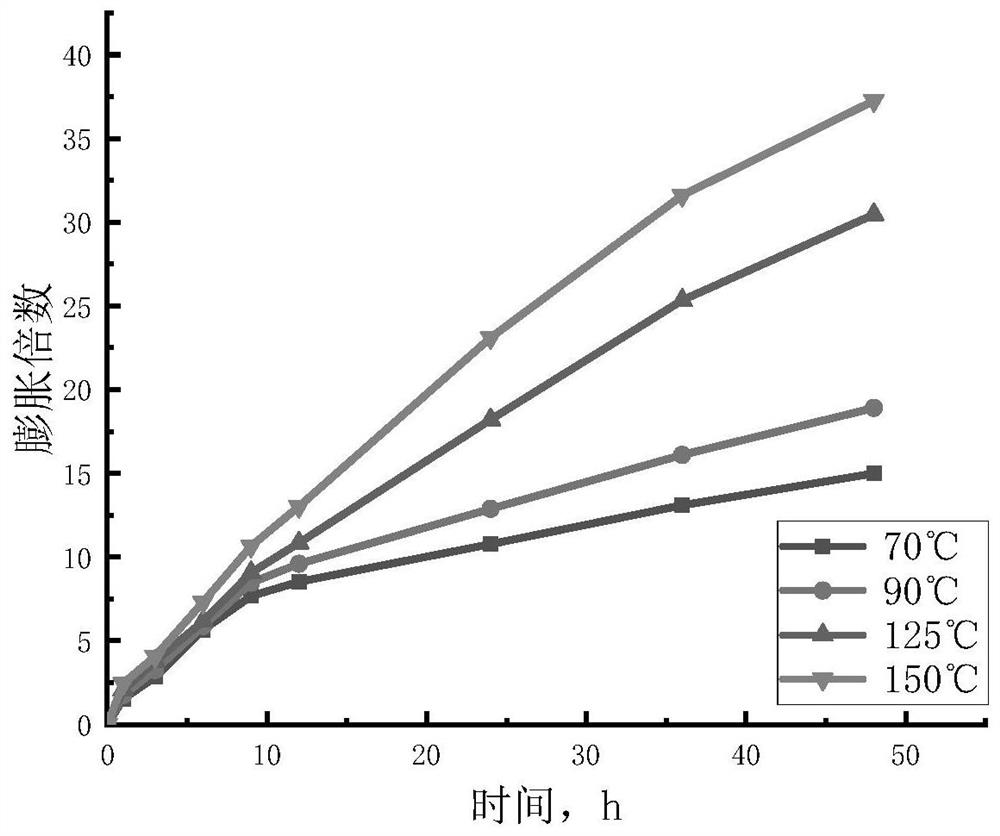

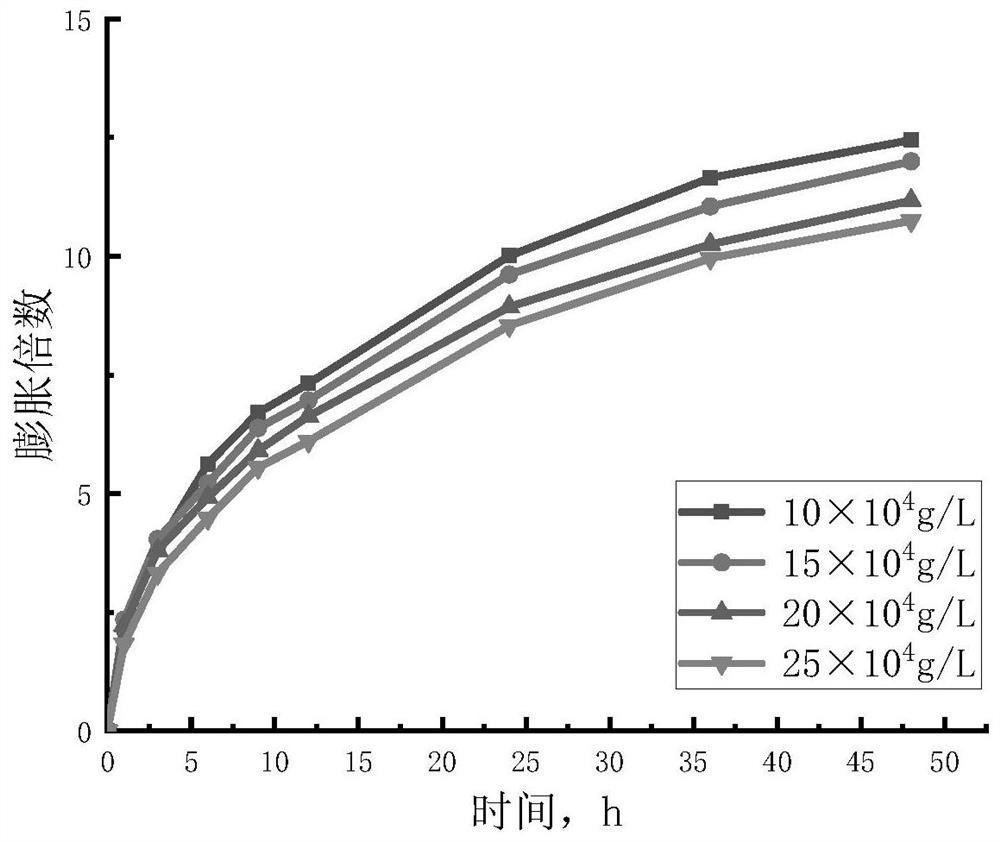

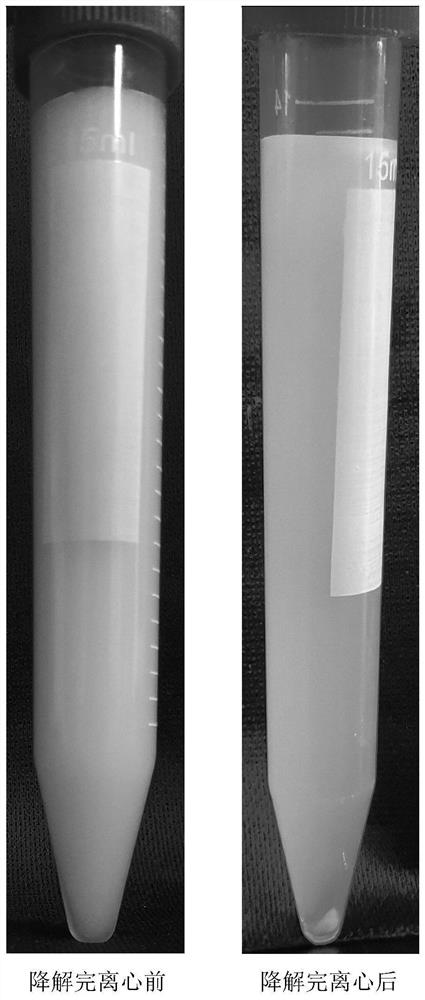

[0049] The following methods are used to further illustrate the effect of the water-swellable rubber flexible temporary plugging particles prepared in the above examples.

[0050] The prepared salinity is 10×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com