Asphalt regenerant and preparation method thereof

A technology of asphalt regenerator and plasticizer, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of poor regeneration effect and poor low temperature resistance of asphalt mixture, and achieves the solution of poor water resistance and improvement of resistance. Low temperature performance, good regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

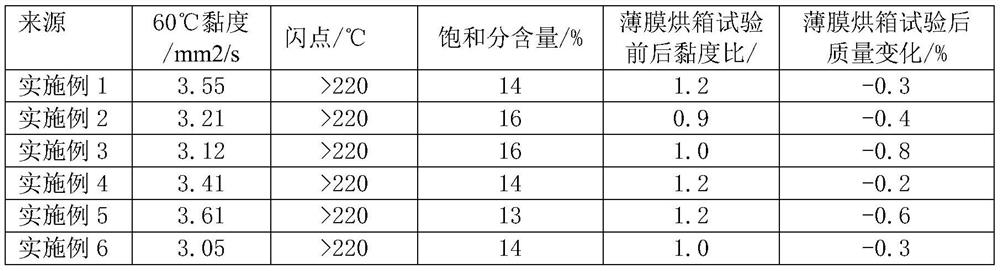

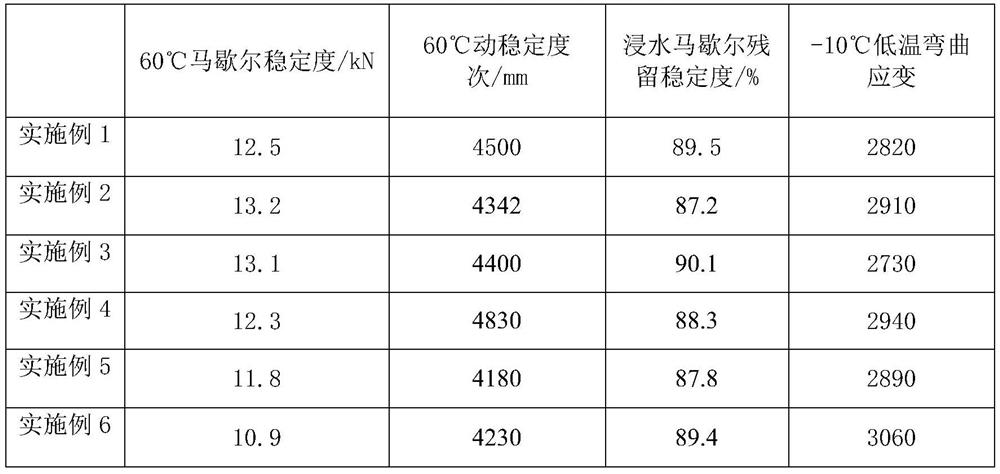

Examples

Embodiment 1

[0028] Asphalt regenerant, which specifically adopts the following raw materials and is prepared according to the following steps:

[0029] S1: Heat 100kg of plasticizer (including 25kg of recycled waste engine oil, 25kg of furfural oil, 25kg of recycled edible vegetable oil and 25kg of dioctyl phthalate) to 160°C, stir for 30 molecules, and then add 10kg of powdered natural rubber (commercially available) and 5kg anti-aging agent (composed of ultraviolet absorber UV-9, antioxidant 1010 and rubber anti-aging agent 4040NA according to mass ratio 1:1:1), stirred for 60 minutes at 165°C, 500-800rpm;

[0030] S2: Then add 5kgSIS (Baling Petrochemical Co., Ltd.), stir at 165°C, 500-800rpm for 30 minutes; then shear at a shear rate of 8000rpm for 30 minutes, then stir at 165°C, 500-800rpm 60 minutes;

[0031] S3: Add 3 kg of stearic acid amide anti-stripping agent to the mixture obtained in S2, and stir for 30 minutes at 165° C. and 500-800 rpm.

Embodiment 2-6

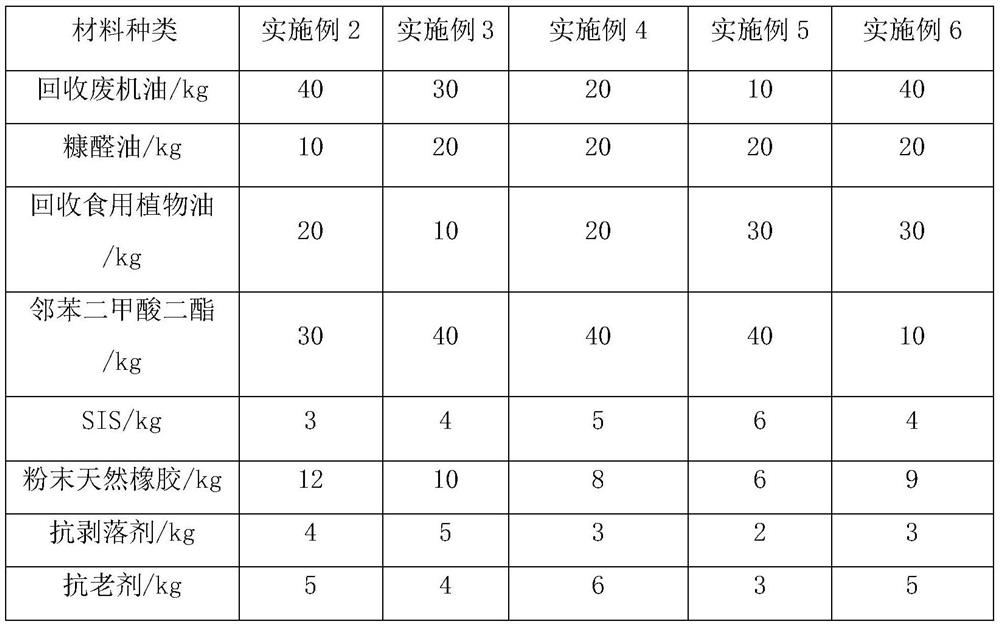

[0033] Except for the conditions shown in Table 1, other parameter settings in Examples 2-6 are exactly the same as in Example 1.

[0034] Table 1 Example 2-6

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com