White anti-yellowing cow split leather processing formula, processing technology and equipment

A kind of processing equipment and anti-yellowing technology, which is applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., which can solve the high cost of spraying structure , yellowing of cattle second-layer leather products, unsatisfactory anti-yellowing, etc., to achieve the effect of reducing the cost of use and ensuring the surface cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

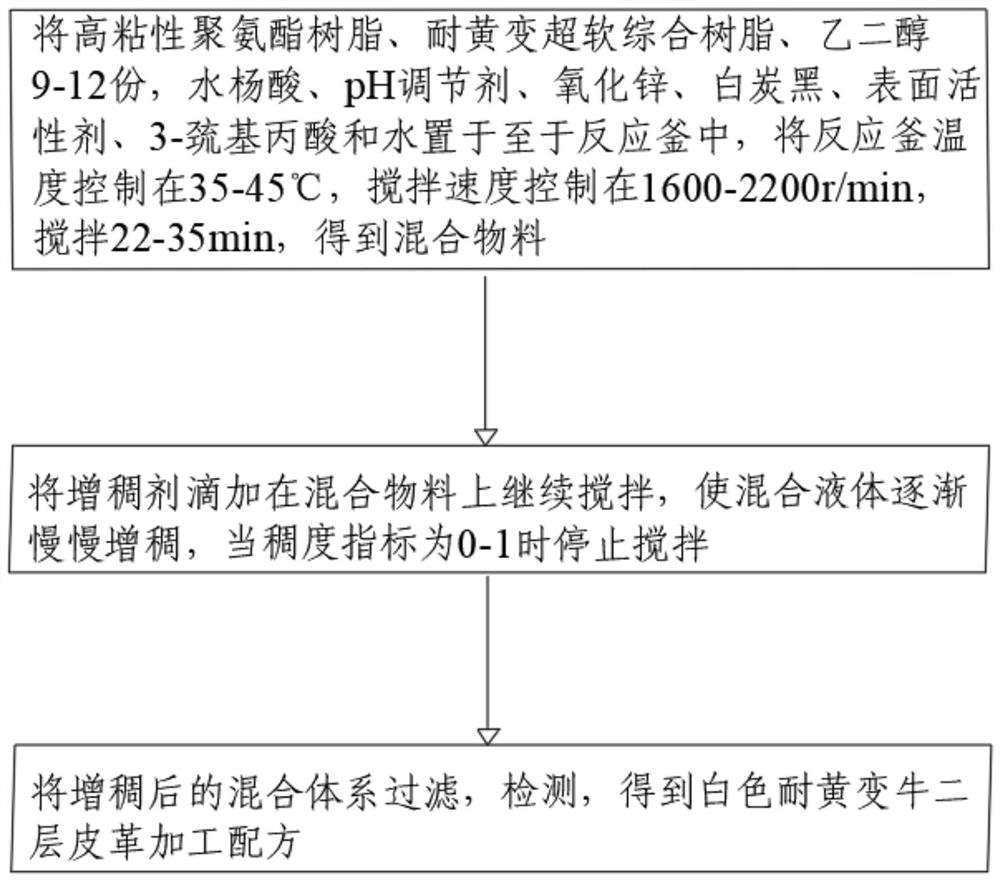

[0044] Such as figure 1 As shown, a white anti-yellowing cattle split leather processing formula, the white anti-yellowing cattle split leather processing formula is composed of the following components by weight: 12-20 parts of high-viscosity polyurethane resin, anti-yellowing super soft comprehensive resin 2.3-5.8 parts, 9-12 parts of ethylene glycol, 0.1-1.5 parts of salicylic acid, 1-5 parts of pH regulator, 0.01-0.05 parts of zinc oxide, 0.02-0.06 parts of white carbon black, 0-10 parts of surfactant 0.8-3.2 parts of 3-mercaptopropionic acid, 30-70 parts of water, and 0.05-0.08 parts of thickener.

[0045] A kind of processing technology of white anti-yellowing bovine split leather processing formula, the specific steps are as follows:

[0046] Step 1. Put high-viscosity polyurethane resin, anti-yellowing ultra-soft comprehensive resin, 9-12 parts of ethylene glycol, salicylic acid, pH regulator, zinc oxide, white carbon black, surfactant, 3-mercaptopropionic acid and wa...

Embodiment 2

[0051] Embodiment 2 is a further improvement to Embodiment 1.

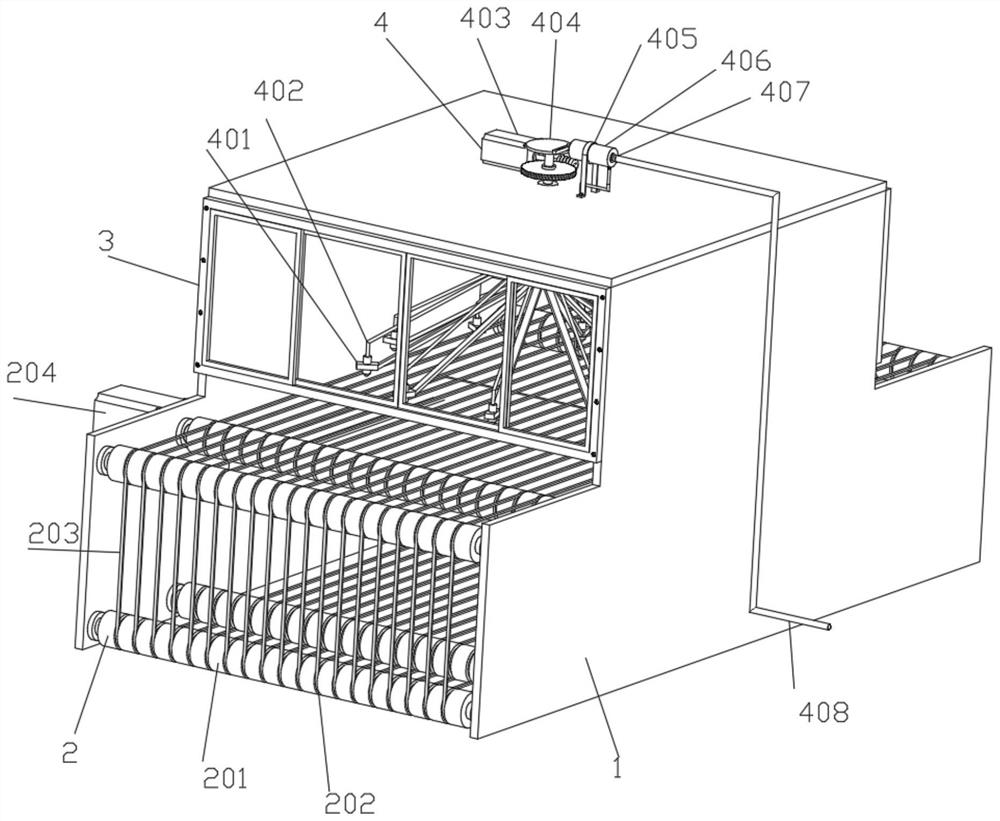

[0052] Such as figure 2 , 3 , 4, 5, 6, 8, 9, 10, and 11 show a kind of white anti-yellowing cow split leather processing equipment, including a frame 1, and the frame 1 is connected with a driving structure for moving the cow split leather 2. The driving structure 2 includes a driving roller 201, an annular groove 202, a driving steel wire 203 and a first driving motor 204. The inner wall of the frame 1 is rotatably connected to the driving roller 201 through a fixedly connected bearing, and the driving roller 201 is uniformly provided with an annular groove 202 A driving steel wire 203 is movably connected in the annular groove 202, and the cow split leather is on the driving steel wire 203, wherein a set of driving rollers 201 is fixedly connected with the output end of the first driving motor 204, and the driving roller 201 is fixedly installed on the frame on the outer wall of 1;

[0053] Frame 1 is connec...

Embodiment 3

[0057] Embodiment 3 is a further improvement to Embodiment 1.

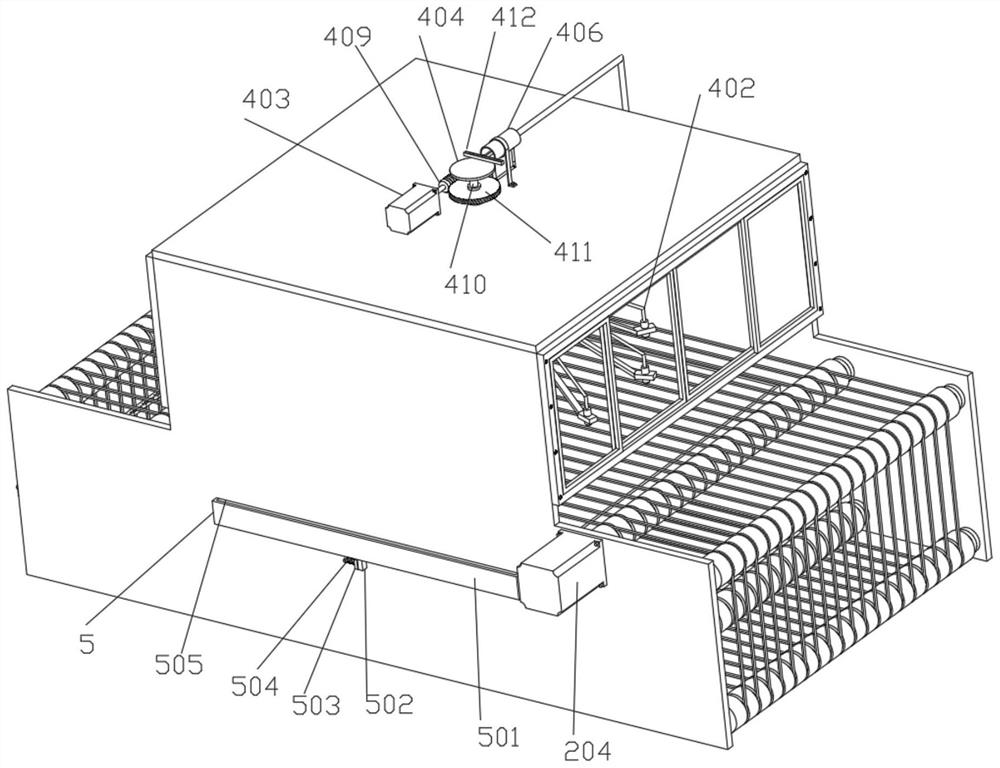

[0058] Such as image 3 ,7 As shown, the frame 1 is provided with a waste collection structure 5 for spraying waste collection below the driving roller 201 on the upper side, and the waste collection structure 5 includes a material receiving box 501, a connecting block 502, a protrusion 503, and a first tension spring 504 , jack 506 and first latch 507, movable slot 505 is offered on the side wall of frame 1, and the inner wall of movable slot 505 fits and slides and is connected with receiving box 501, and the left side wall of receiving box 501 and the inner wall of frame 1 Fitting contact, the bottom of the outer end of the receiving box 501 is fixedly connected with a connection block 502, the side wall of the connection block 502 is provided with a socket 506, the side wall of the connection block 502 is slidably connected with a protrusion 503, and the side wall of the protrusion 503 The first extension spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com