Delayed curing UV adhesive and preparation method thereof

A curing type, aluminum sheet technology, applied in the direction of adhesives, epoxy resin adhesives, non-polymer organic compound adhesives, etc., can solve the problems of insufficient exposure of transparent substrates, affecting the performance of optical products, and complex application scenarios. Achieve good toughness, small curing shrinkage, and promote the effect of dark reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

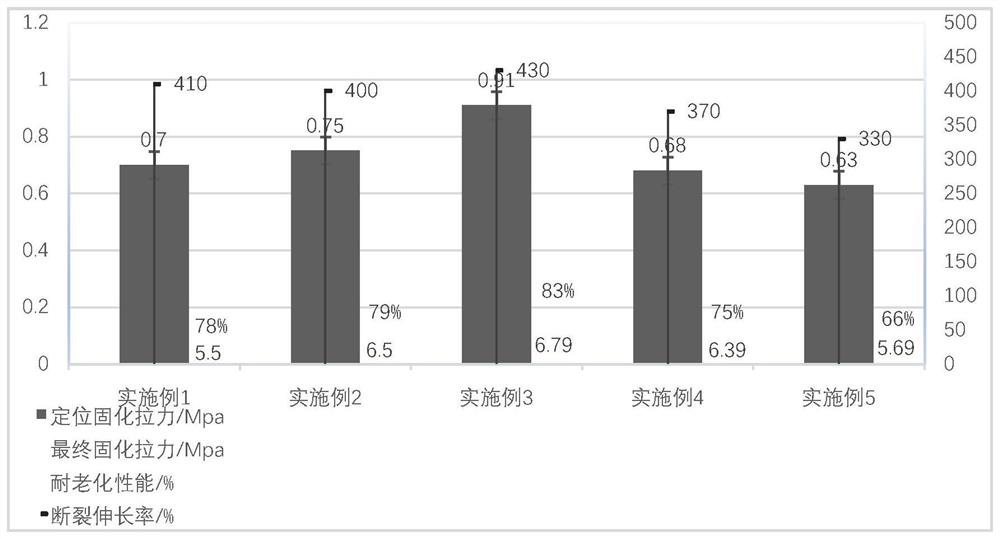

Examples

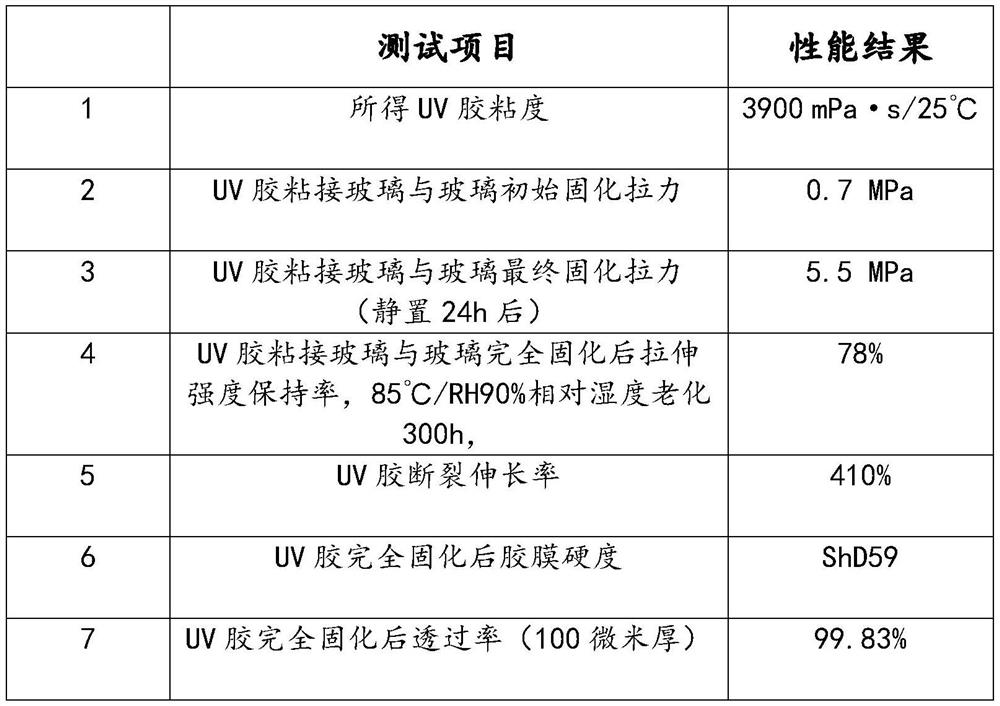

Embodiment 1

[0024] Based on 100 parts by weight proportioning, prepare the UV glue composition according to the following formula:

[0025] components Name of raw material provider Mass % Prepolymer 6148J75 Changxing Chemical 40 epoxy resin 2021P Nantong Synasia New Materials Co., Ltd. 20 active monomer 2-HEMA BASF 30 Auxiliary 2-28 Nantong Synasia New Materials Co., Ltd. 1.67 coupling agent 171 Wacker 1.67 antioxidant ADK STAB 517 Japan Adico 1.67 Initiator A 1173 Huatai Chemical 1.67 Initiator B 101 Guangyi Chemical 3.5

[0026] Preparation:

[0027] Add the prepolymer, epoxy resin, active monomer, auxiliary agent, silane coupling agent, antioxidant, photoinitiator, etc. into the three-dimensional mixer in sequence, with a total of 100g, and keep the temperature not higher than 50 degree, select 1000 rev / min, under the condition of avoiding light, disperse and mix for 10 minutes, and then filter...

Embodiment 2

[0049] Prepare UV glue composition according to following formula (preparation method and test method are identical with embodiment one):

[0050]

[0051] The various aspects performance of the UV glue that embodiment two obtains is as follows:

[0052]

Embodiment 3

[0054] Prepare UV glue composition according to following formula (preparation method and test method are identical with embodiment one):

[0055]

[0056] The various aspects performance of the UV glue that embodiment three obtains is as follows:

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com