Raw coal alcohol group liquefaction process and heating power clean combustion method based on RSG engineering technical effect

An engineering technology and thermal combustion technology, which is applied in the field of raw coal alcohol liquefaction process and thermal clean combustion, can solve the problems of carbon steel series metal corrosion, hidden dangers of pressure equipment safety, and high production cost of industrial grade methanol chemical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

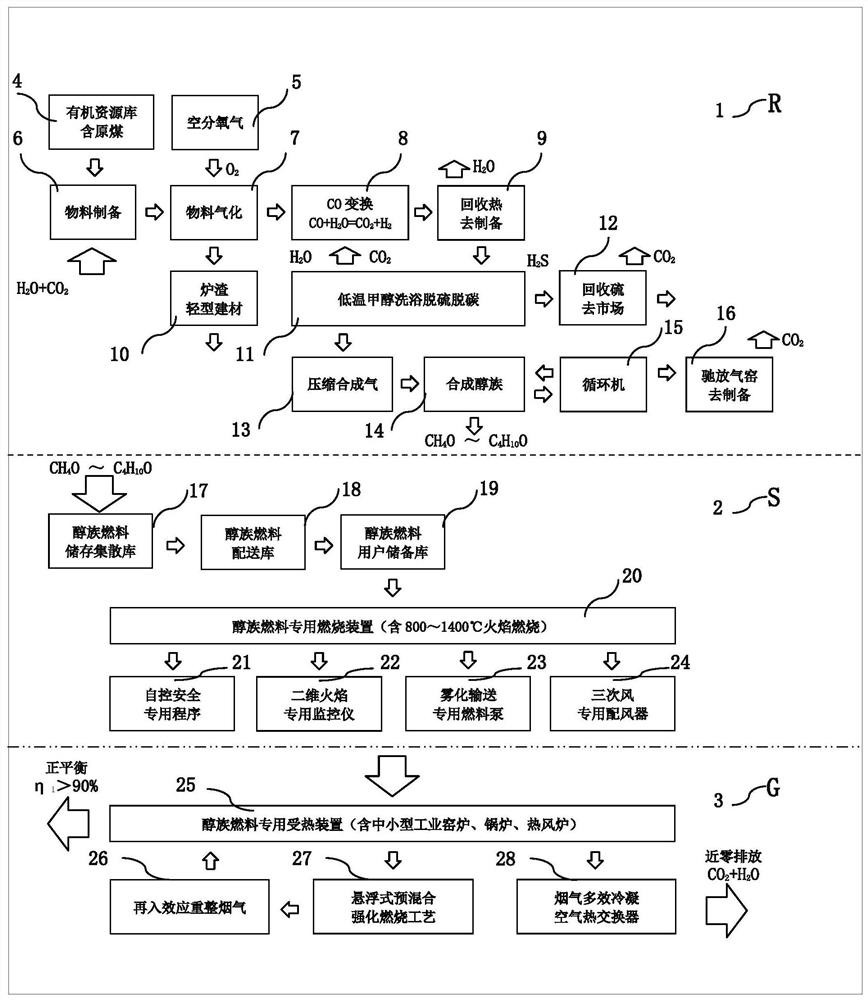

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, a raw coal alcohol liquefaction process and thermal clean combustion method based on the RSG engineering technology effect proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and an implementation case .

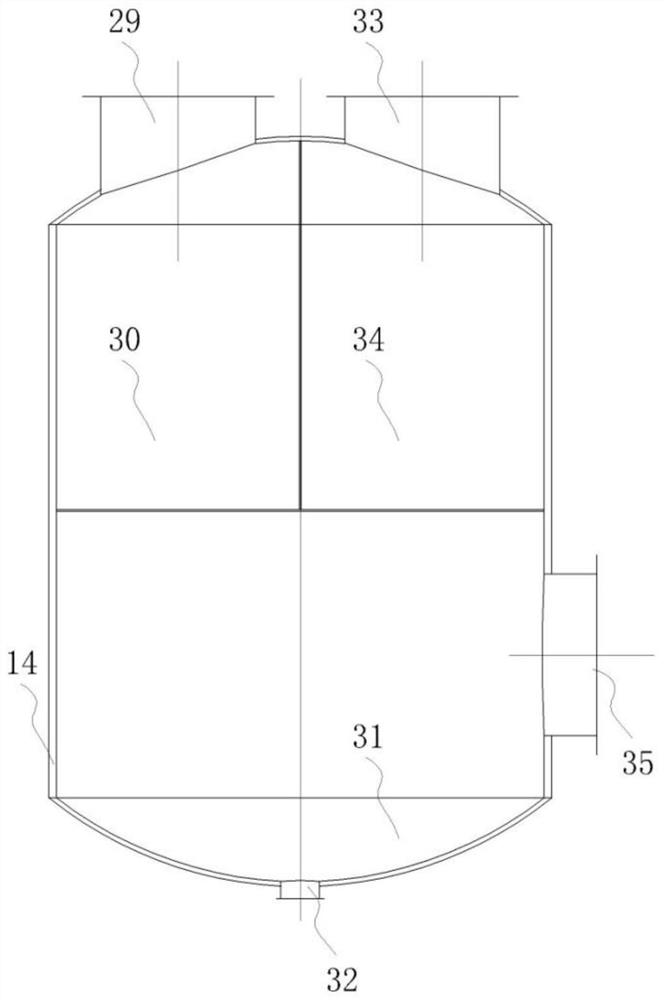

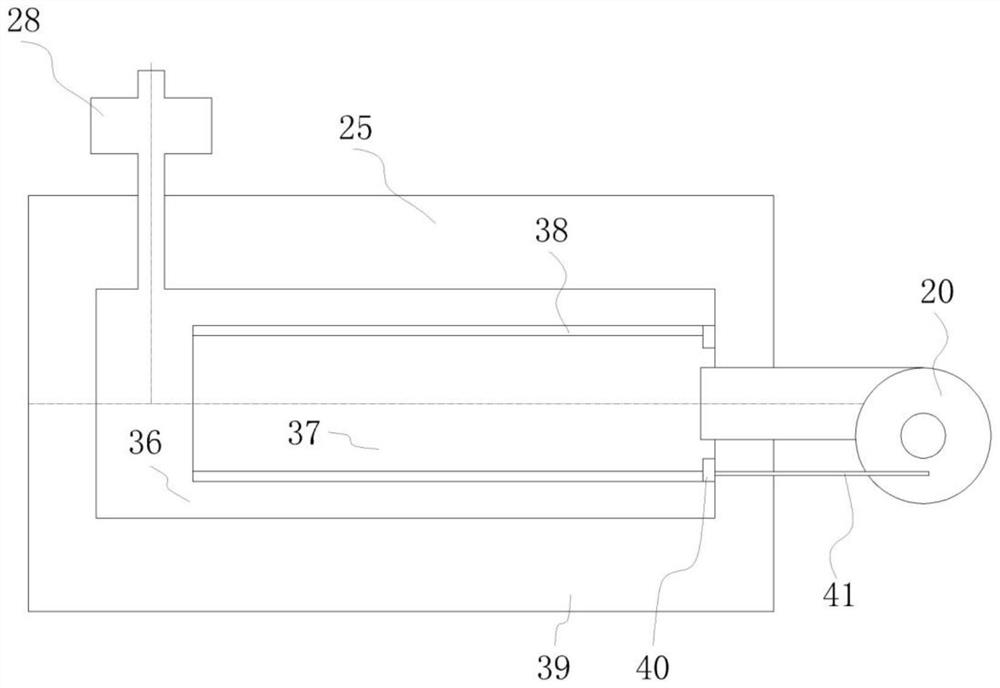

[0026] refer to figure 1 , this embodiment discloses a raw coal alcohol group liquefaction process and thermal clean combustion method based on the RSG engineering technology effect, including a standard alcohol group fuel R unit (1) to liquefy coal into low-carbon alcohol group CH that can be commonly used in the industrial field 4 O~C 4 h 10 O Clean energy, transported by pipelines and tank trains or tank trucks and connected to the special combustion equipment S unit (2); the special combustion equipment S unit (2) uses special combustion and heating equipment for the characteristic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com