Cold and hot mixed blast furnace liquid slag treatment device

A processing device and technology for liquid slag, applied in the field of blast furnace slag processing in the metallurgical industry, can solve the problems of poor recovery efficiency, large water consumption, low waste heat energy level, etc., and achieve the effect of good cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

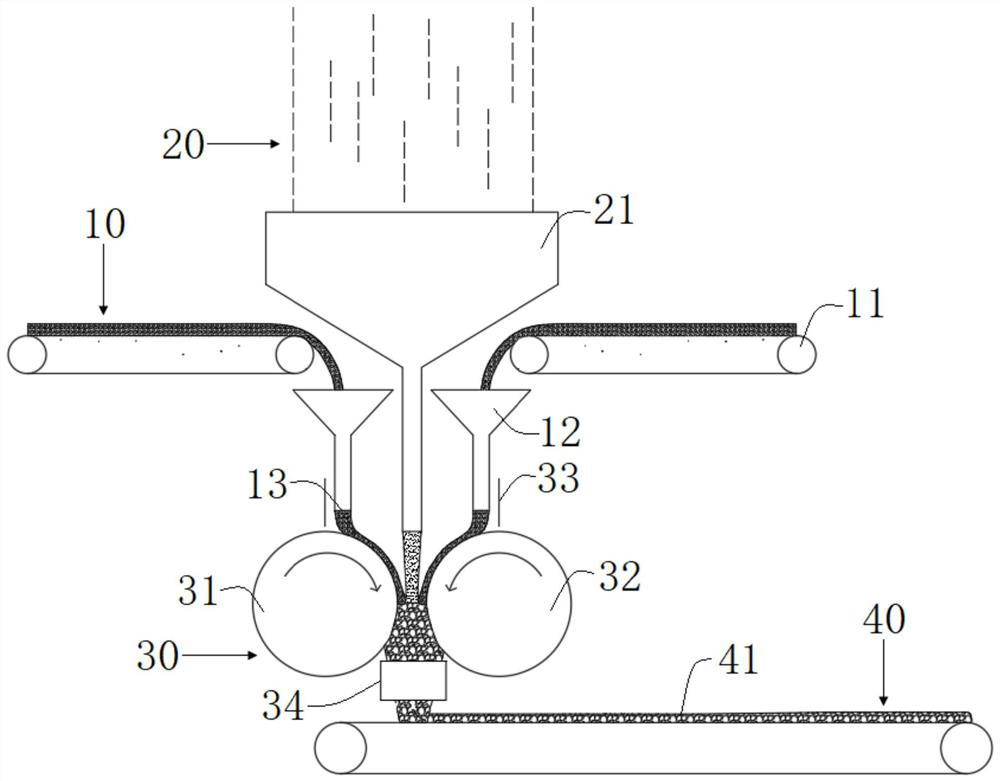

[0038] Such as figure 1 and figure 2 As shown, a cold and hot double mixed blast furnace liquid slag processing device in this embodiment includes a cold slag feeding unit 10, a hot slag feeding unit 20, a solidification unit 30 and a slag transport unit 40, a cold slag feeding unit 10 and a hot slag feeding unit. The feeding unit 20 is located above the curing unit 30 , the hot slag feeding unit 20 is arranged between the two cold slag outlets 13 , and the slag transport unit 40 is arranged below the curing unit 30 . The cold slag on both sides of the hot slag covers the hot slag on both sides to form a "temperature sandwich cake" type high-temperature slag, which not only solves the problem of insufficient vitrification rate if the cooling speed is too slow, but also solves the problem that the cooling speed is too fast to achieve waste heat. The question of recycling. At the same time, this treatment method has solved the problem of slag sticking to the roller caused by ...

Embodiment 2

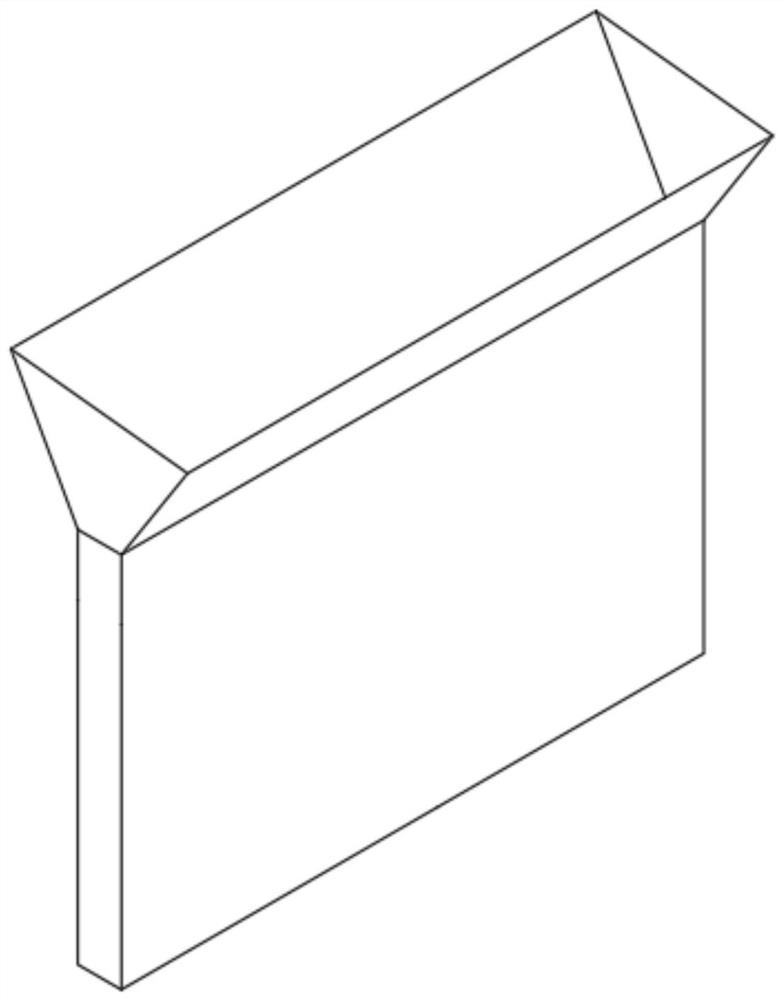

[0048] This embodiment is basically the same as Embodiment 1, the difference is that the curing unit 30 also includes a baffle 33, the baffle 33 is arranged above the first roller 31 and the second roller 32, and the baffle 33 mainly prevents the slag overflow phenomenon, the baffle plate 33 is set above the first drum 31 and the second drum 32, when the cold slag and hot slag are transported too fast or the slag overflows due to equipment failure, the baffle plate 33 can stop the overflowing slag The slag is effectively blocked to prevent the slag from contaminating the equipment. The baffle 33 can be set as a covering type, and a frame set in a certain shape surrounds the top of the first drum 31 and the second drum 32 .

Embodiment 3

[0050] This embodiment is basically the same as Embodiment 1, the difference is that the curing unit 30 further includes a drop channel 34 , and the drop channel 34 is arranged below the gap between the first roller 31 and the second roller 32 . The falling channel 34 mainly plays the role of heat preservation, and a waste heat recovery device or equipment can be arranged on the falling channel 34 to recover the thermal energy of the molten slag. There is a thermal insulation device outside the slag tank 21, and the slag tank 21 also has a flow regulating function. The above-mentioned molten slag flows into the slag tank 21 from the slag tank. In order to make the ratio of cold slag and hot slag appropriate, the flow rate of the hot slag needs to be controlled. Control, the slag outlet is equipped with a flow regulating device, which can adjust the flow of molten liquid slag according to the temperature value of high-temperature solid slag during operation. The implementation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com