Closed fixed type annular turbojet steam wheel

A steam turbine, fixed technology, applied in stators, non-variable-capacity engines, engine components, etc., can solve problems affecting service life, corrosion of parts, steam waste, etc., to extend service life, avoid corrosion, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

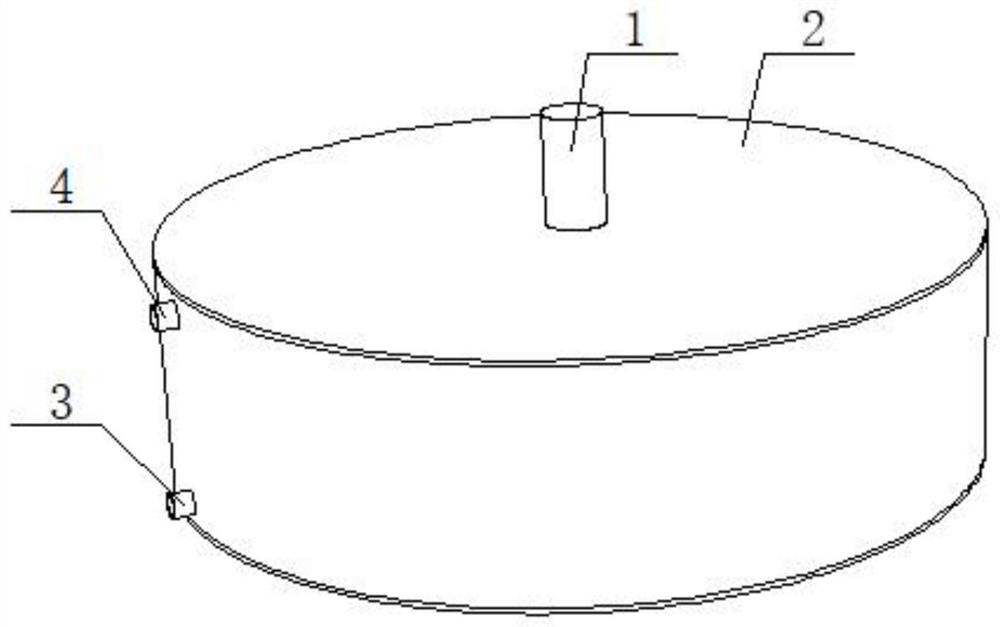

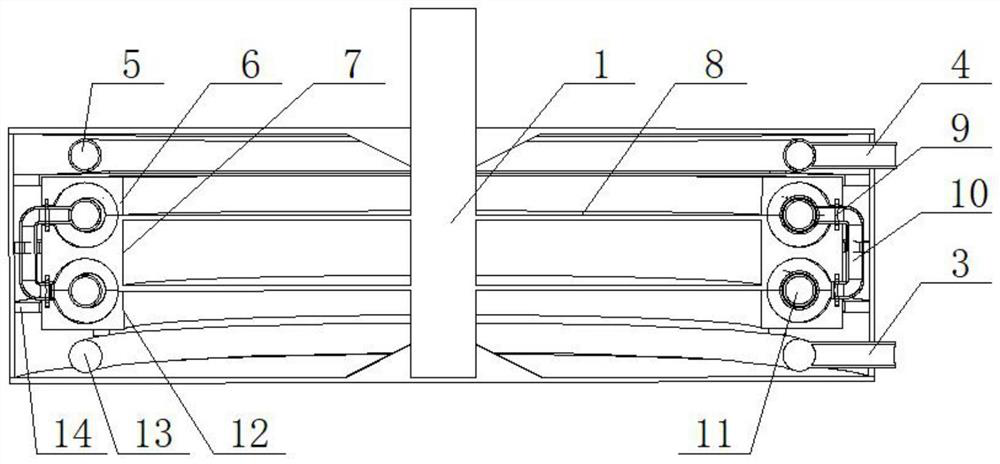

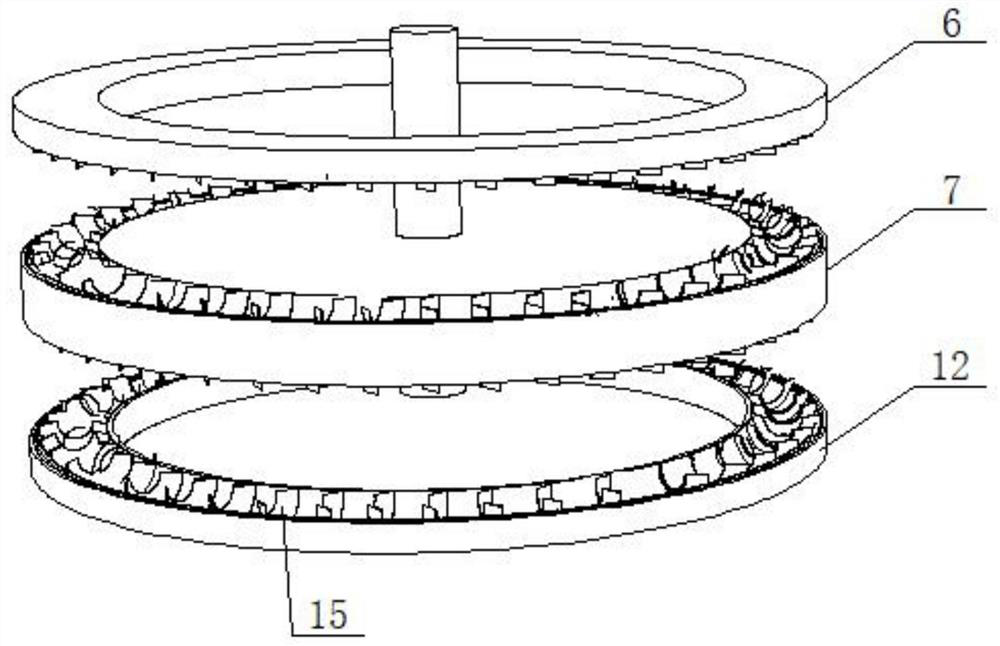

[0033] A closed and fixed annular turbojet steam turbine, which is innovative in that it includes a casing 2, a main shaft 1, a sealed injection chamber, a sealing ring piece 9 and an injection ring 11, and the casing is composed of a side wall, a top plate and a bottom plate , the side wall surrounds a cylindrical cylinder, and the upper and lower ends of the cylindrical cylinder are respectively provided with a top plate and a bottom plate, and a main shaft is installed in the interior of the shell along its axial rotation, and the upper end of the main shaft is formed by The top plate of the shell is pierced to form the output end, and a sealed spray chamber linked with it is installed on the inner main shaft of the shell, a spray ring is wrapped and installed in the sealed spray chamber, and a seal ring piece that rotates relative to it is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com