Assembling method of guiding device and oil seal of damper

An assembly method and a technology of guides, which are applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of damage to the ring seal, affecting the assembly efficiency of the shock absorber, and the inability to realize the assembly method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

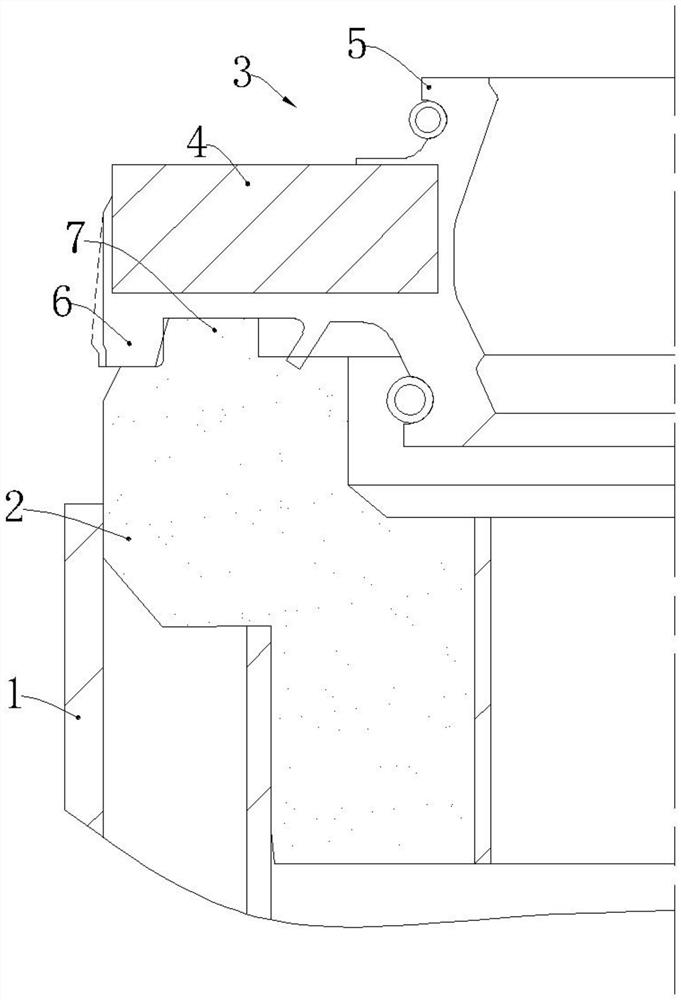

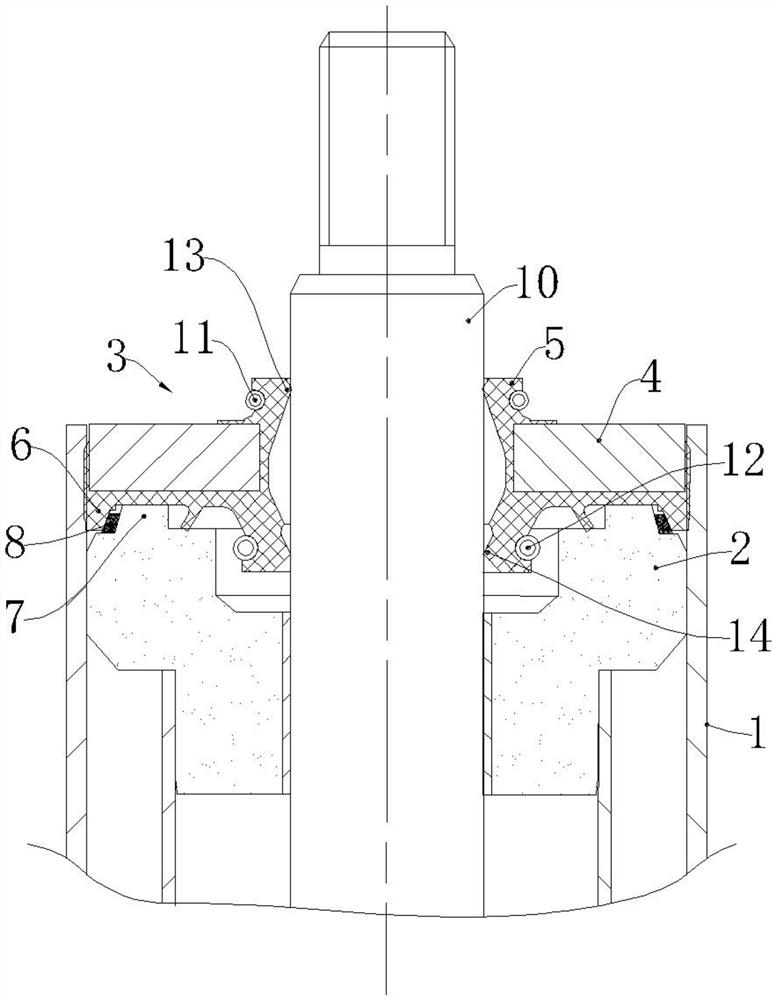

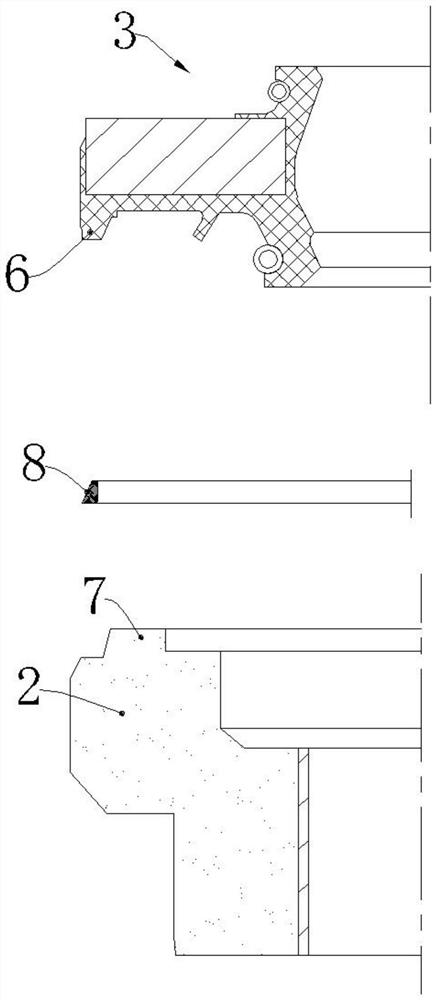

[0021] Figure 2-Figure 6 Embodiment 1 of the present invention is shown.

[0022] Such as figure 2 As shown, a shock absorber includes an outer cylinder 1 , a guide 2 , an oil seal 3 , an auxiliary mounting ring 8 , and a piston rod 10 . Both the guide 2 and the oil seal 3 are installed inside the outer cylinder 1 . The guide 2 and the oil seal 3 are sleeved on the outside of the piston rod 10 .

[0023] The oil seal 3 includes a metal frame 4 , a rubber body 5 , a first holding spring 11 , and a second holding spring 12 . The metal skeleton 4 and the rubber body 5 are vulcanized into one body, and the lower end of the rubber body 5 is provided with an annular sealing body 6, and the inner surface of the annular sealing body 6 is conical in shape with a small top and a large bottom.

[0024] The upper end of the guide 2 is provided with an annular boss 7, and the outer surface of the annular boss 7 is conical in shape with a small top and a big bottom.

[0025] The auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com