Femoral stem prosthesis electrolytic machining cathode and femoral stem prosthesis electrolytic machining device

A technology for processing devices and femoral stems, which is applied in the direction of electric processing equipment, electrochemical processing equipment, and accessory devices, can solve the problems of low processing accuracy, high processing cost, and low efficiency, and achieve good surface quality of finished products and reduce processing costs , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

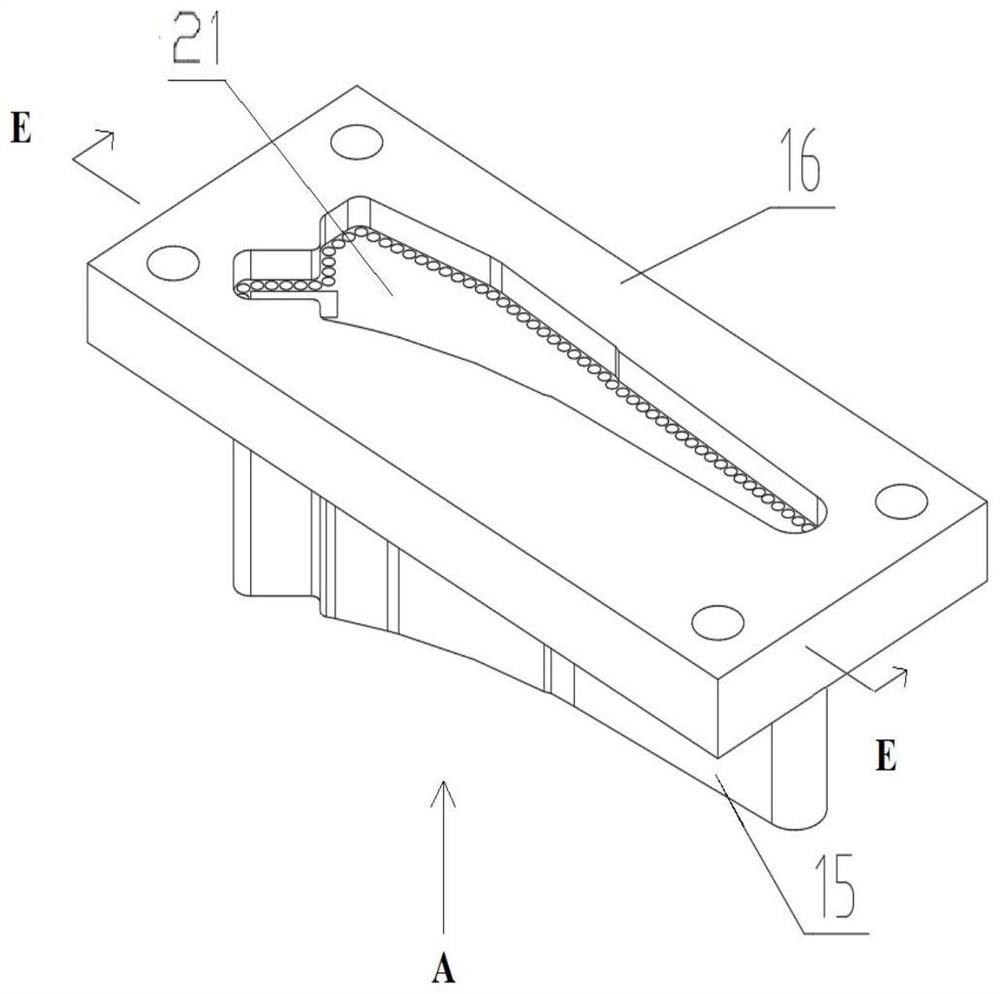

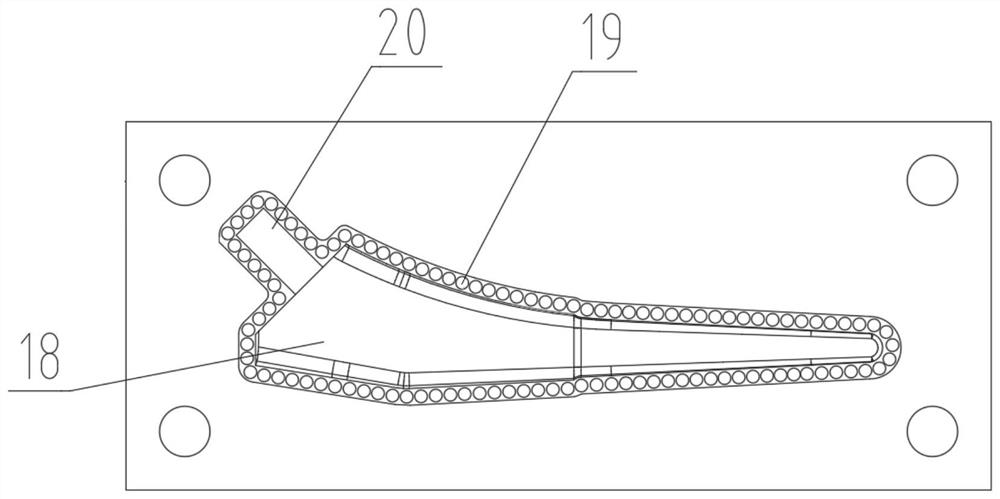

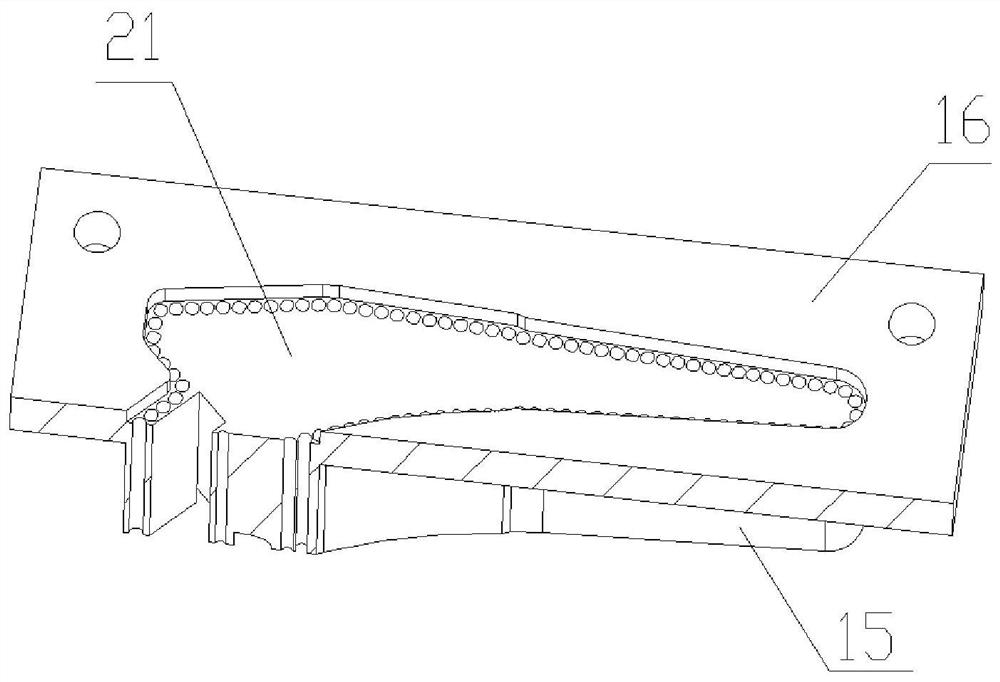

[0035] Such as Figure 1 to Figure 4 As shown, a femoral stem prosthesis electrolytically processed cathode includes a cathode base plate 16 and a cathode forming body 15 located on one side of the cathode base plate 16. The end face of the cathode forming body 15 away from the cathode base plate 16 is the processed end face, and the profile of the processed end face Adapt to the outline of the cross-section of the femoral stem prosthesis at its symmetry plane, the edge position of the processed end face is provided with the outline through hole 19 that runs through the cathode molding main body 15 and the cathode base plate 16, and the outline of the outline through hole 19 on the processed end surface is consistent with The profile of the section of the femoral stem prosthesis at its symmetry plane is consistent, and an inner cavity 18 adjacent to the profile through hole 19 is also provided on the processed end surface, and the inner profile of the inner cavity 18 is symmetr...

Embodiment 2

[0042] This embodiment is similar to Embodiment 1, except that, in this embodiment, the diameter of the contour through hole 19 is 2 mm. The structure and working principle of other parts of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0044] This embodiment is similar to Embodiment 1, except that, in this embodiment, the diameter of the contour through hole 19 is 4 mm. The structure and working principle of other parts of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com