Production process of high-strength rivet nut

A rivet nut and production process technology, applied in the high-strength rivet nut process and fastener field, can solve the problem of insufficient strength of the rivet nut, and achieve the effects of high strength, preventing decarburization and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

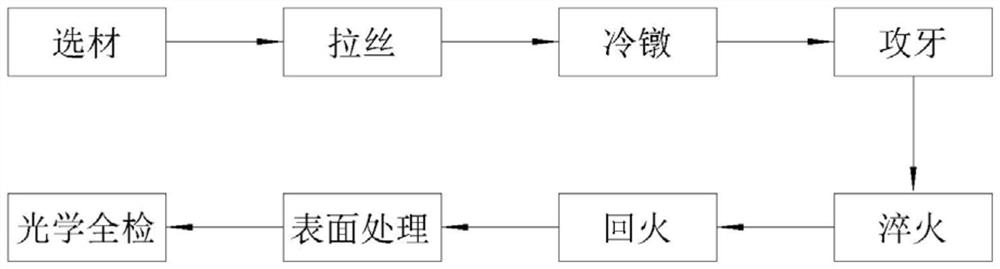

[0022] see figure 1 , a production process of a high-strength rivet nut of the present invention comprises the following steps:

[0023] a. Material selection: choose 20MnTiB as the blank material;

[0024] b. Drawing: The blank material is drawn by a drawing machine and transformed into a profile that meets the size requirements;

[0025] c. Cold heading: put the profile into the cold heading machine for cold heading to obtain the rivet nut;

[0026] d. Tapping: Put the rivet nut into the tapping machine for tapping;

[0027] e. Quenching: quench the formed rivet nuts in a heating furnace, control the quenching temperature to be 880°C, the heating time is 6 hours, the holding time is 1 hour, and then rapidly cooled in oil at 60°C;

[0028] f. Tempering: Temper the rivet nut after quenching, control the tempering temperature to 480 ℃, the heating time is 3 hours, and the holding time is 5 hours;

[0029] g. Surface treatment: Put the heat-treated rivet nut in an aqueous so...

Embodiment 2

[0033] see figure 1 , a production process of a high-strength rivet nut of the present invention comprises the following steps:

[0034] a. Material selection: choose 20MnTiB as the blank material;

[0035] b. Drawing: The blank material is drawn by a drawing machine and transformed into a profile that meets the size requirements;

[0036] c. Cold heading: put the profile into the cold heading machine for cold heading to obtain the rivet nut;

[0037] d. Tapping: Put the rivet nut into the tapping machine for tapping;

[0038] e. Quenching: Quenching the formed rivet nut in a heating furnace, controlling the quenching temperature to be 850°C, the heating time of 4 hours, the holding time of 0.5 hours, and then rapidly cooled in oil at 50°C;

[0039] f. Tempering: Temper the rivet nut after quenching, control the tempering temperature to 450 °C, the heating time is 2 hours, and the holding time is 3 hours;

[0040] g. Surface treatment: Put the heat-treated rivet nut in an ...

Embodiment 3

[0044] see figure 1 , a production process of a high-strength rivet nut of the present invention comprises the following steps:

[0045] a. Material selection: choose 20MnTiB as the blank material;

[0046] b. Drawing: The blank material is drawn by a drawing machine and transformed into a profile that meets the size requirements;

[0047] c. Cold heading: put the profile into the cold heading machine for cold heading to obtain the rivet nut;

[0048] d. Tapping: Put the rivet nut into the tapping machine for tapping;

[0049] e. Quenching: quench the formed rivet nut in a heating furnace, control the quenching temperature to be 910 °C, the heating time is 8 hours, the holding time is 1.5 hours, and then rapidly cooled in oil at 70 °C;

[0050] f. Tempering: Temper the rivet nut after quenching, control the tempering temperature to 510 °C, the heating time is 4 hours, and the holding time is 6 hours;

[0051] g. Surface treatment: Put the heat-treated rivet nut in an aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com