Concrete pumping agent and preparation process thereof

A concrete pump and production process technology, applied in the field of concrete admixtures, can solve the problems of not being developed and reducing the amount of cement, and achieve the effect of saving resources, reducing the amount of cement, and reducing the amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: A concrete pumping agent, which is made by mixing the following raw materials in the mass proportion: 93% of tailings, 7% of slag, and 5% of grinding aid.

[0013] The grinding aid in this embodiment can help increase the grinding output and eliminate static electricity; the slag in this embodiment is an active substance that can improve the coagulation strength of concrete, and has the effect of eliminating static electricity.

Embodiment 2

[0014] Embodiment 2: A kind of manufacture craft of concrete pumping agent, is after tailings 93%, slag 7% and grinding aid 5% are mixed, put into double closed-circuit ball mill grinding system and grind, in grinding process In the experiment, the rotational speed of the double closed-circuit ball mill grinding system was set at 1200 rpm, so that the particles of 0.25-100 µm were obtained as the pumping agent.

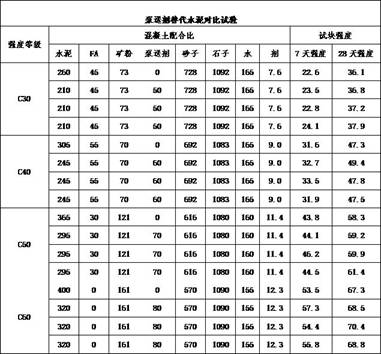

[0015] The pumping agent in this embodiment is mixed in the concrete of different counterweights according to the specification of 50-80KG per cubic meter, and the comparison test after 7 days and 28 days is as follows:

[0016]

[0017] It can be concluded from the above table that adding 50-80KG per cubic meter of pumping agent to concrete instead of cement will not affect the strength of the test block, which is within the range of national standards.

[0018] The cement in the above experiment is PO42.5 cement, the mineral powder is S95 mineral powder, FA secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com