High-hardness and high-wear resistance refractory high-entropy intermetallic compound coating and preparation method thereof

An intermetallic compound, high wear resistance technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of high brittleness, difficult processing, difficult to apply to large engineering components, etc., to achieve good protection effect, crack sensitivity The effect of low resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

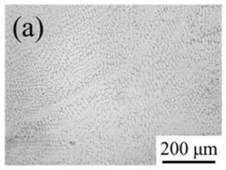

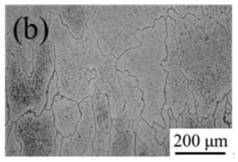

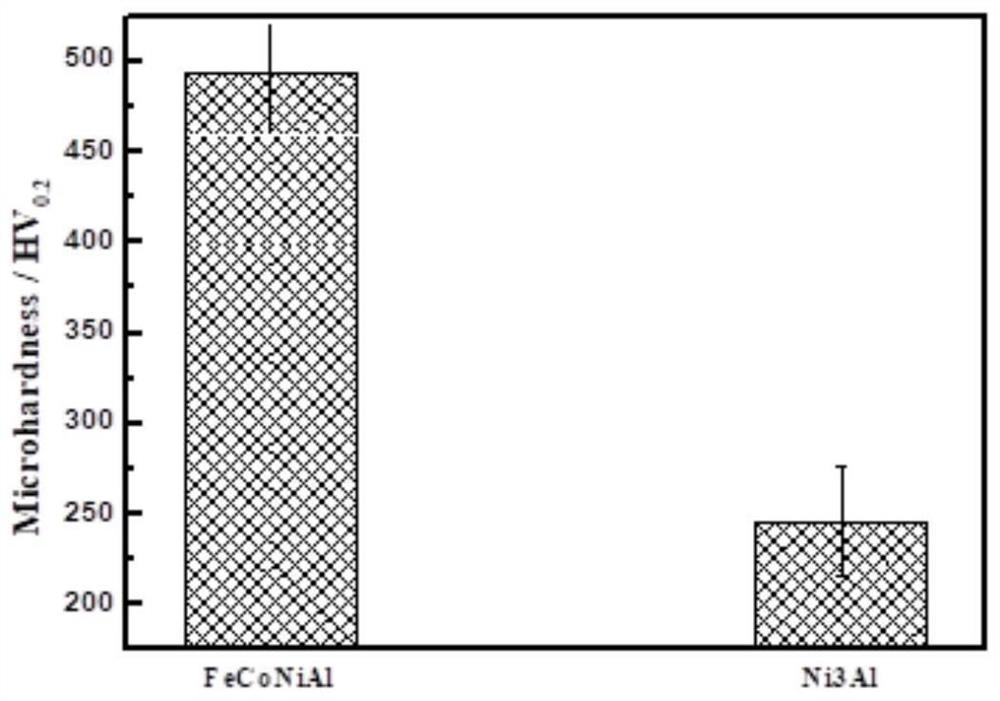

Image

Examples

Embodiment 1

[0027] A refractory high-entropy intermetallic compound coating with high hardness and high wear resistance is prepared according to the following steps:

[0028] 1) For powder preparation, Fe, Co, Ni and Al metal powders are selected and mixed evenly in a molar ratio of 1:1:1:1. The purity of Fe, Co, Ni and Al metal powders is greater than or equal to 99.6%, and the powder particle size is 45 -105 μm.

[0029] 2) Powder ball milling, the above-mentioned mixed powder is placed in a stainless steel ball mill tank for ball milling for 2 hours, the speed of the ball mill is 300rmp / s, after the powder after ball milling passes through a 200 mesh sieve, it is placed in a vacuum desiccator for future use;

[0030] 3) Grinding the base material, using 45# steel plate with a size of 40mm×30mm×10mm as the base material, and removing the cladding surface scale on the grinder and sandpaper, after that, cleaning the surface oil with alcohol and drying it with a hair dryer. Store dry.

...

Embodiment 2

[0033] A refractory high-entropy intermetallic compound coating with high hardness and high wear resistance is prepared according to the following steps:

[0034] 1) For powder preparation, Fe, Co, Ni and Al metal powders are selected and mixed evenly in a molar ratio of 1:1:1:1. The purity of Fe, Co, Ni and Al metal powders is greater than or equal to 99.6%, and the powder particle size is 45 -105 μm.

[0035] 2) Powder ball milling, the above-mentioned mixed powder is placed in a stainless steel ball mill tank for ball milling for 2 hours, the speed of the ball mill is 300rmp / s, after the powder after ball milling passes through a 200 mesh sieve, it is placed in a vacuum desiccator for future use;

[0036] 3) Grinding the base material, using 45# steel plate with a size of 40mm×30mm×10mm as the base material, and removing the cladding surface scale on the grinder and sandpaper, after that, cleaning the surface oil with alcohol and drying it with a hair dryer. Store dry.

...

Embodiment 3

[0039] A refractory high-entropy intermetallic compound coating with high hardness and high wear resistance is prepared according to the following steps:

[0040] 1) For powder preparation, Fe, Co, Ni and Al metal powders are selected and mixed evenly in a molar ratio of 1:1:1:1. The purity of Fe, Co, Ni and Al metal powders is greater than or equal to 99.6%, and the powder particle size is 45 -105 μm.

[0041] 2) Powder ball milling, the above-mentioned mixed powder is placed in a stainless steel ball mill tank for ball milling for 2 hours, the speed of the ball mill is 300rmp / s, after the powder after ball milling passes through a 200 mesh sieve, it is placed in a vacuum desiccator for future use;

[0042] 3) Grinding the base material, using 45# steel plate with a size of 40mm×30mm×10mm as the base material, and removing the cladding surface scale on the grinder and sandpaper, after that, cleaning the surface oil with alcohol and drying it with a hair dryer. Store dry.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap