Aluminum and aluminum alloy etching clean production process

A clean production and etching technology, applied in the field of industrial wastewater treatment, can solve the problem of not forming a recycling method, and achieve the effects of reducing cost and environmental protection pressure, prolonging life, and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

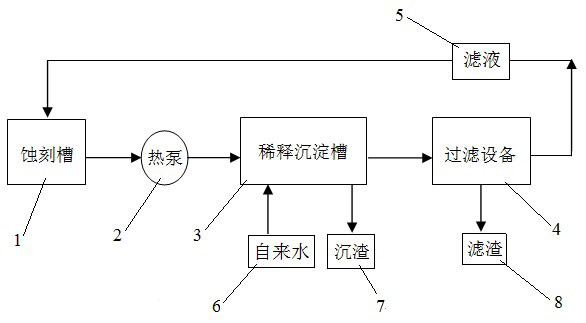

[0032] Example 1: Such as figure 1 As shown, aluminum and its alloy etching cleaning production processes include the following steps:

[0033] (1) Cooling dilution:

[0034] From the etch tank 1, the etching groove 1 is extracted from the etching groove 1 to the dielectric etching liquid to the dilution precipitation tank 3, and the inlet port of the heat pump 2 is located below the 1 / 2 liquid surface of the etching groove 1 depth, while pumping The flow rate is mixed from the self-coming water 6, which is mixed into the flow rate of the self-contained water 6 to save the flow rate of the etching liquid, and the amount of tap water 6 and the extracted etching solution are 1: 1 to dilute the precipitated dilution tank 3. The post-etching fluid temperature drops to 40 to 60 ° C.

[0035] (2) Presets of the suspension of the precipitation: After cooling and diluting the etching liquid precipitation for 5 hours, the larger suspension of the particles is removed by the sediment 7.

[...

Embodiment 2

[0039] Example 2: Such as figure 1 As shown, aluminum and its alloy etching cleaning production processes include the following steps:

[0040] (1) Cooling dilution:

[0041] From the etching groove 1, the etching groove 1 is extracted from the etching groove 1 to the dielectric etching fluid to the dilution precipitation tank 3, and the inlet port of the heat pump 2 is located below the 1 / 2 liquid surface of the etching groove 1, and somed The flow rate is mixed from the self-coming water 6, which is mixed into the flow rate of the self-contained water 6 to save the flow rate of the etching liquid, and the amount of tap water 6 and the extracted etching solution are 1: 1 to dilute the precipitated dilution tank 3. The post-etching fluid temperature drops to 40 to 60 ° C.

[0042] (2) Precipitation removal of suspension: After cooling and diluted etching liquid precipitation for 4 hours, the larger suspension of the particles is removed by the sediment 7.

[0043] (3) Filter remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com