Sand gushing and water gushing prevention freezing pipe drill rod pulling-out device and drill rod pulling-out process for subway tunnel construction

A technology for tunnel construction and water freezing, which is used in earth-moving drilling, wellbore/well components, sealing/sealing, etc. It can solve the problems of sand gushing and water, affecting the smooth progress of construction, etc., so as to improve construction efficiency and ensure sealing. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Drill pipe removal device for anti-sand gushing and water freezing pipe drilling in subway tunnel construction, such as Figure 4 and Figure 5 As shown, including sealing mechanism 3, pulling rod mechanism and driving mechanism;

[0041] The sealing mechanism 3 includes a rubber plug 14 and a flange 15. There are two flanges 15. The rubber plug 14 is fixedly installed between the two flanges 15. The rubber plug 14 and the flange 15 are fixedly installed together to form a flange rubber seal. The diameter of the flange 15 matches the inner diameter of the drill pipe 1 to be removed so that the flange 15 fits with the inner wall of the drill pipe 1 to be removed; the flange rubber seal is fixedly installed at the mouth of the drill pipe 1 to be removed , and the sealing fit between the inner wall of the drill pipe 1 to be removed; the outer end face of the flange rubber seal is movably connected with the hydraulic cylinder 4 of the rod pulling mechanism; the flange rubb...

Embodiment 2

[0048] Drill pipe removal device for anti-sand gushing and water freezing pipe drilling in subway tunnel construction, such as Figure 6 As shown, including sealing mechanism 3, pulling rod mechanism and driving mechanism;

[0049] The sealing mechanism 3 includes a rubber plug 14 and a flange 15. There are two flanges 15. The rubber plug 14 is fixedly installed between the two flanges 15. The rubber plug 14 and the flange 15 are fixedly installed together to form a flange rubber seal. The diameter of the flange 15 matches the inner diameter of the drill pipe 1 to be removed so that the flange 15 matches the inner wall clearance of the drill pipe 1 to be removed; the flange rubber seal is fixedly installed at the mouth of the drill pipe 1 to be removed, and Sealing cooperation with the inner wall of the drill pipe 1 to be removed; the outer end surface of the flange rubber seal is vertically connected with the support rod 11 of the rod pulling mechanism;

[0050] The pull-out...

Embodiment 3

[0055] The drilling pipe removal process for preventing sand gushing and water freezing in subway tunnel construction includes the following steps:

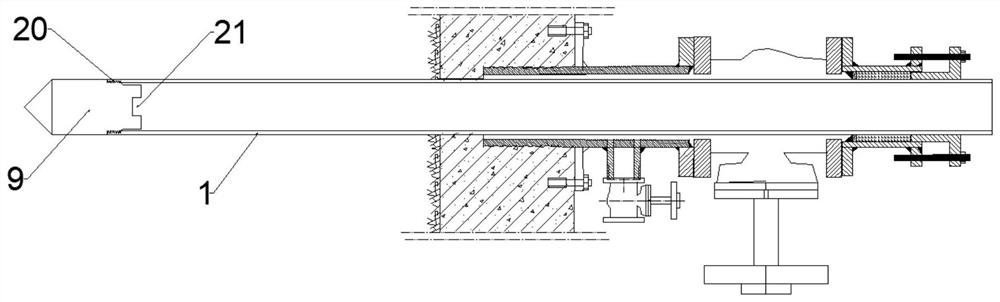

[0056] Step A: the drilling is completed; the length of each section of the drill pipe used is 1.5 meters, and the drill pipe and the drill bit 9 are connected by threads 20, see figure 1 ;

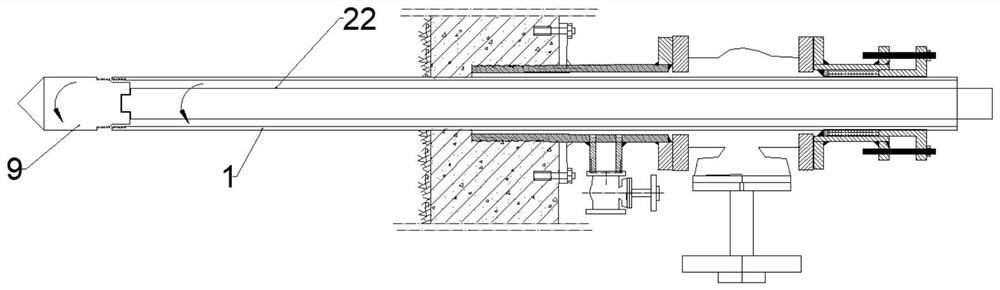

[0057] Step B: After the drilling is completed, extend the unloading screw 22 and fix it relatively through the slot 21, rotate the unloading screw 22, unscrew the drill bit 9 and the drill pipe 1 to be removed, and disconnect the thread 20, see figure 2 ;

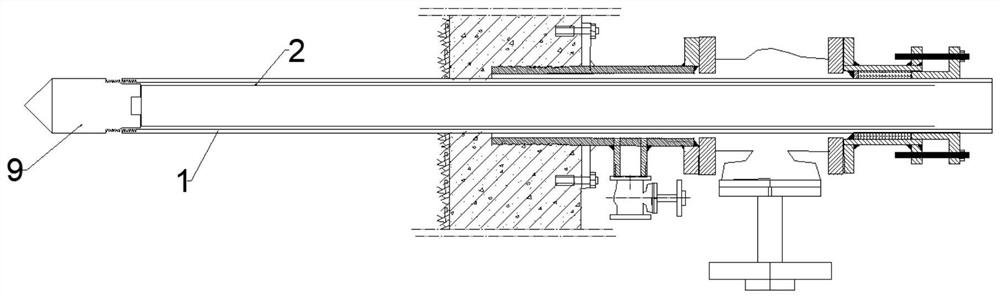

[0058] Step C: Insert the free tube 2 into the inner cavity of the drill pipe and extend into the bottom of the drill hole, see image 3 ;

[0059] Step D: use the subway tunnel construction anti-sand escaping water freezing tube drill pipe removal device of embodiment 2 to remove the drill pipe 1 to be removed from the borehole, see Figure 6 ;

[0060] Step E: Immediately install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com