A kind of alloy steel brake disc manufactured by laser additive and its manufacturing method

A laser additive and manufacturing method technology, applied in the direction of brake discs, additive manufacturing, additive processing, etc., can solve the problems of stress concentration and reduce the service life of brake discs, so as to improve stress concentration, increase yield, increase The effect of structural stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

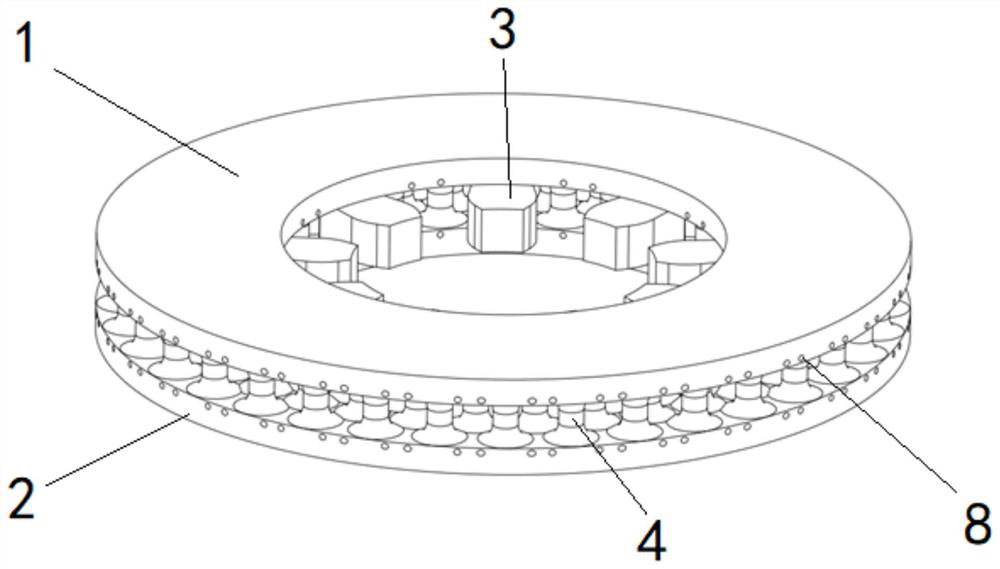

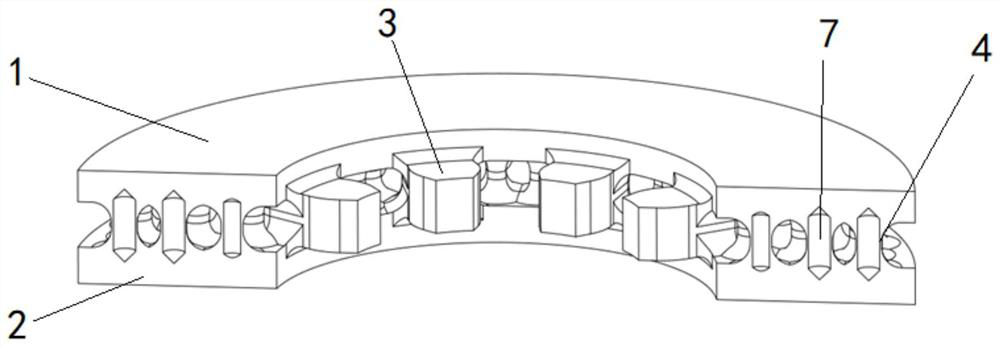

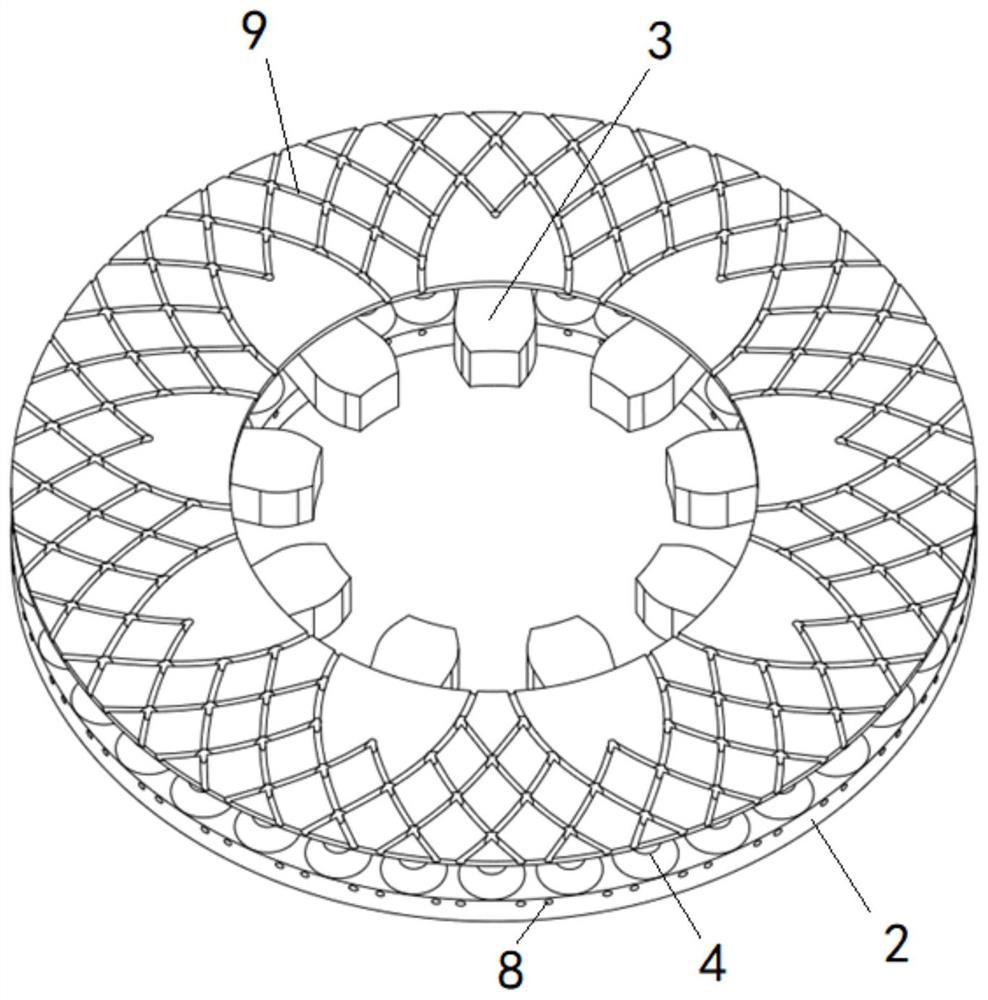

[0033] The specific technical solutions of the present invention are further described with the accompanying drawings of the structure specification below.

[0034] as attached figure 1 As shown in -4, an alloy steel brake disc manufactured by laser additive manufacturing of the present invention includes an upper disc surface 1 , a lower disc surface 2 , a claw structure 3 and a heat dissipation rib 4 .

[0035]The cooling rib 4 includes a cylindrical section in the middle and two arc transition sections that smoothly transition and connect with the upper and lower ends of the cylindrical section. The centerlines of the segments are collinear, the heat dissipation rib 4 is located between the upper disk surface 1 and the lower disk surface 2, and the two arc transition sections of the heat dissipation rib 4 are respectively connected with the inner surfaces of the upper disk surface 1 and the lower disk surface 2. 4. There is a hollow heat dissipation rib cavity 7 inside. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com