Efficient pulverized coal industrial boiler

A technology for industrial boilers and pulverized coal, which is applied in block/powder supply/distribution, combustion methods, and fuel supply regulation, etc., can solve the problems of reduced accuracy, low accuracy and uniformity, and waste of resources, and achieves Ensure accuracy and uniformity, improve uniformity and accuracy, and avoid the effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

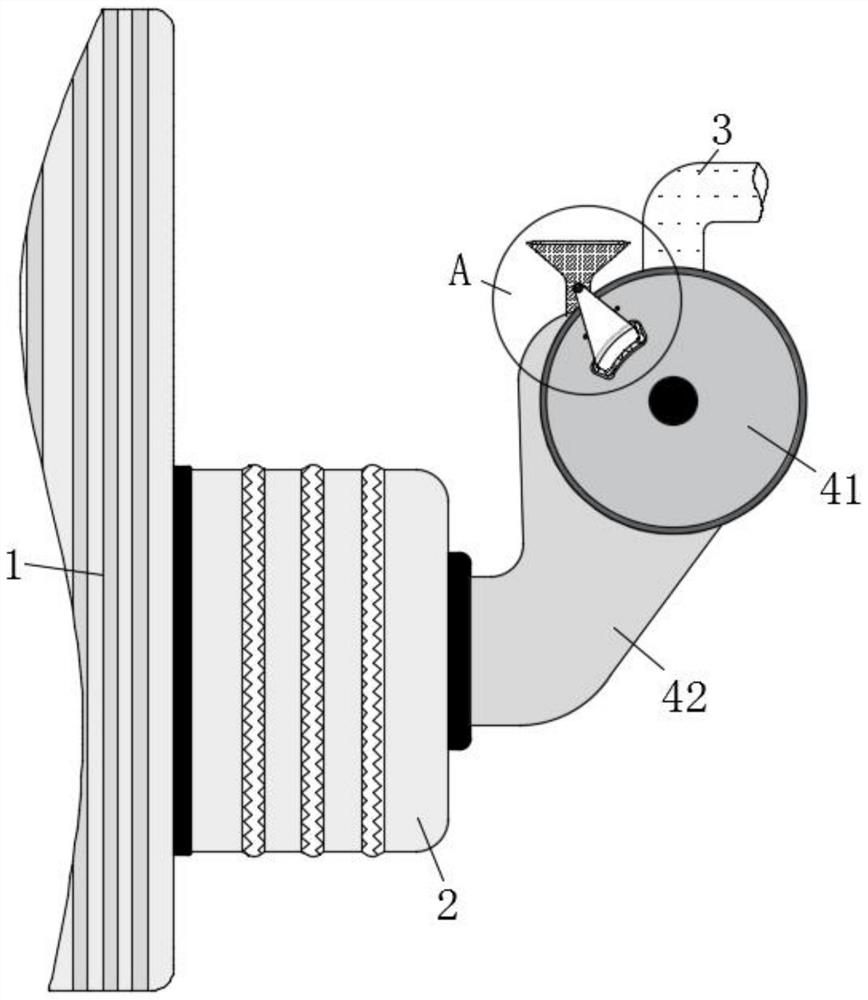

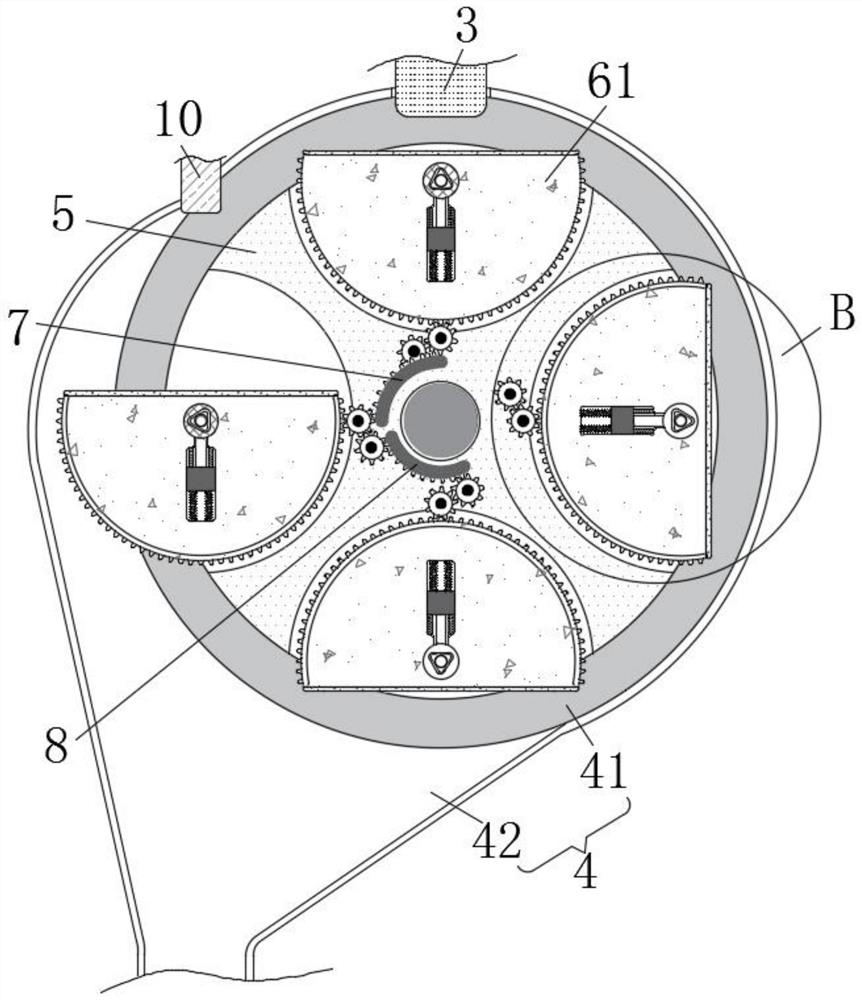

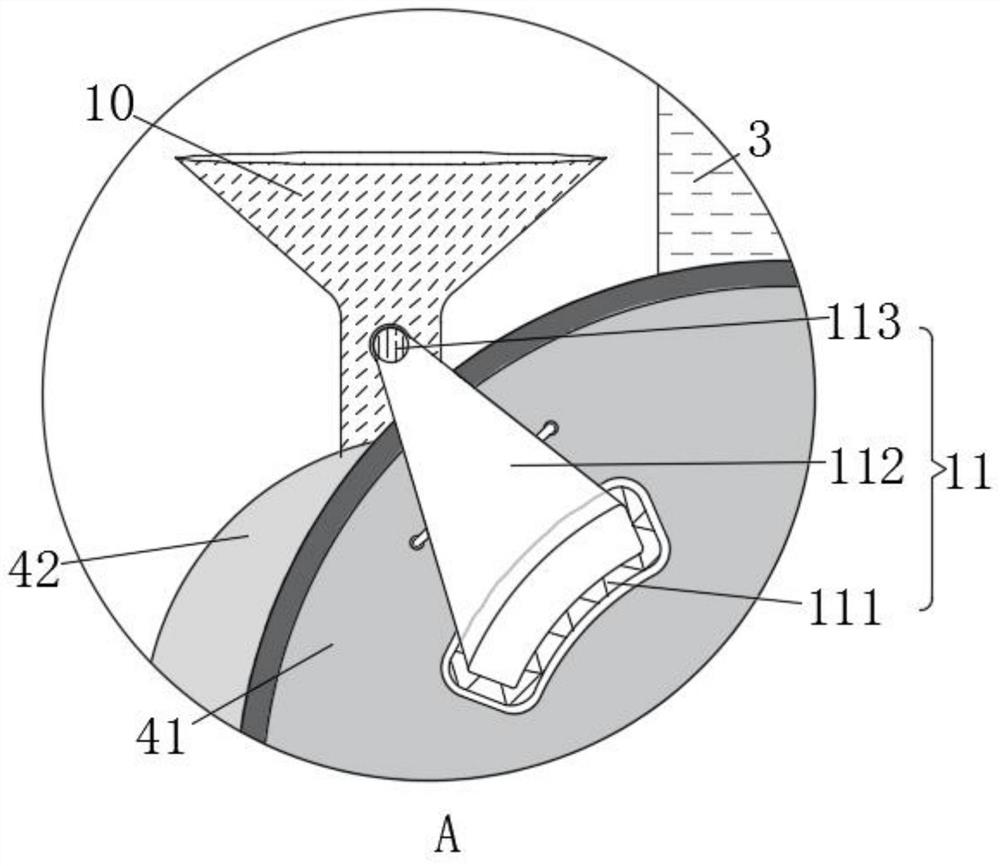

[0032] Such as Figure 1-6 As mentioned above, a storage guide shell 4 is sealedly connected between the pulverized coal delivery pipe 3 and the burner 2, and a cylindrical piece 5 is rotatably connected to the inside of the storage guide shell 4, and a semi-cylindrical groove is evenly embedded on the side of the shaft of the cylindrical piece 5 Assemblies 6, on the inner wall of the housing guide shell 4 are fixedly provided with arc-shaped co-direction tooth segments 7 and arc-shaped reset tooth segments 8, and the semi-cylindrical groove components 6 are meshed with arc-shaped co-direction tooth segments 7 With the gear set 9 corresponding to the arc reset tooth section 8, the semi-cylindrical groove assembly 6 includes an inner tank 61, a semi-cylindrical shell 62, a slide block 63 and a telescoping assembly 64, and the inner tank 61 is limited by the slide block 63. The position is slidably embedded in the semi-cylindrical shell 62, and the telescopic assembly 64 is conn...

Embodiment 2

[0037] Among them, the number of semi-cylindrical groove assemblies 6 is four, and the arc-shaped tooth segment 7 is relatively located on the upper part of the arc-shaped reset tooth segment 8, and the two are arranged on the same side as the side tilting auxiliary guide connecting piece 42, and the arc-shaped The same-direction tooth segment 7 and the arc-shaped reset tooth segment 8 are both corresponding to a quarter of the arc length of the circle. At this time, the interval of the semi-cylindrical shell 62 moving in the same direction and the reset interval are 1 / 4 Circle, the design of the overall size ratio data of the equipment is simpler, more convenient for production and manufacturing, and correspondingly reduces the production cost.

[0038] Working principle: In the high-efficiency pulverized coal industrial boiler, the cylindrical part 5 rotates at a constant speed during the boiler's working process. Here, the pulverized coal delivery can be completed by adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com