A distribution transformer

A technology for distribution transformers and transformers, applied in the field of transformers, can solve problems such as poor cooling effect and transformer oil cooling, and achieve good heat conduction effects, accelerated cooling, and accelerated cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

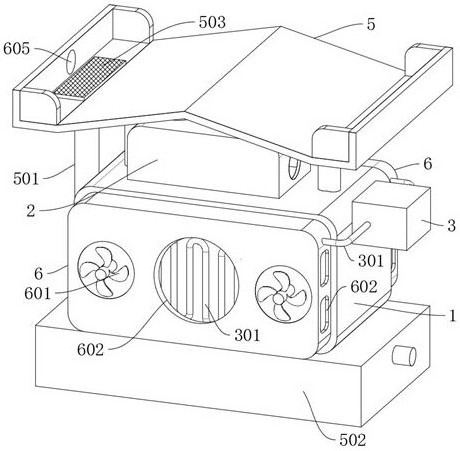

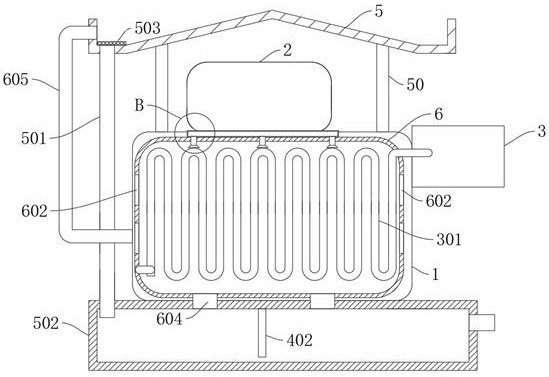

[0032] refer to Figure 1-8 , a distribution transformer, including a transformer device 1, a cooling device 3, and also includes: a return-shaped tube 301, which is arranged on the inside and outside of the transformer device 1, and the output and input ends of the return-shaped tube 301 are connected to the cooling device 3; stirring The assembly is connected in the transformer equipment 1; the water tank 502 is fixedly connected to the bottom of the transformer equipment 1; the protection box 2 is fixedly connected to the top of the transformer equipment 1; the piston cylinder 4 is fixedly connected in the protection box 2, wherein the piston cylinder 4 The water inlet pipe 402 and the water outlet pipe 403 are fixedly connected, and the end of the water inlet pipe 402 away from the piston cylinder 4 leads to the water tank 502; the nozzle 404 is fixedly connected to the end of the water outlet pipe 403 away from the piston cylinder 4, wherein the nozzle 404 is curved toward...

Embodiment 2

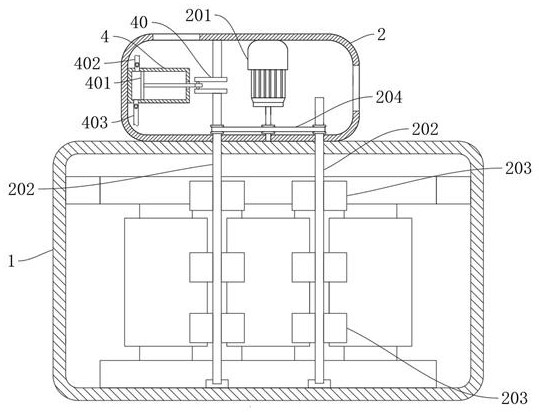

[0041] refer to image 3 , 4 . On the rotating shaft 202, one end of the rotating shaft 202 runs through the transformer device 1, the rotating shaft 202 and the output end of the motor 201 are connected by a belt 204; the motor 201 is inside the protection box 2, the crankshaft 40 is fixedly connected to the rotating shaft 202, and a push rod is slidingly connected in the piston barrel 4 401, one end of the push rod 401 is rotatably connected to the crankshaft 40;

[0042] The rotation of the motor 201 drives the rotating shaft 202 to rotate through the belt 204, and the rotating shaft 202 then drives the stirring fan 203 to stir the transformer oil in the transformer equipment 1;

[0043] At the same time, the motor 201 rotates to drive the crankshaft 40 to rotate, and the crankshaft 40 drives the push rod 401 to reciprocate in the piston barrel 4. When the crankshaft 40 pulls the push rod 401, the water in the water tank 502 is drawn into the piston barrel 4 through the w...

Embodiment 3

[0046] refer to Figure 4 , a distribution transformer, which is basically the same as that of Embodiment 2, furthermore: the stirring assembly is provided with four groups;

[0047] The four sets of stirring components are all connected to the output end of the motor 201 through the belt 204, and then rotated by the motor 201 to drive the four sets of stirring components to stir the transformer oil in the transformer equipment 1 at the same time, so that the transformer oil is more active and fully integrated with the transformer equipment. 1 in contact with the return-shaped tube 301 to improve the cooling efficiency and effect of the transformer oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com