Medical implant and manufacturing method thereof

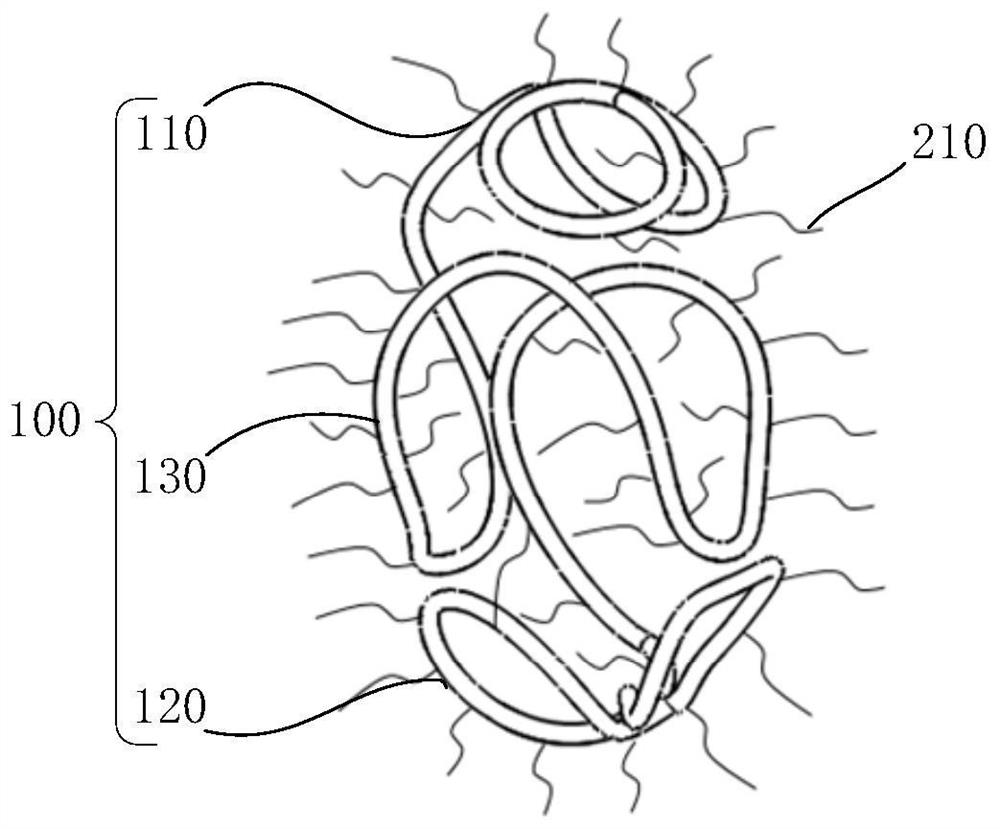

A manufacturing method and implant technology, applied in the field of medical devices, can solve the problems of not being able to fully conform to the shape of the aneurysm, not being able to completely embolize the aneurysm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

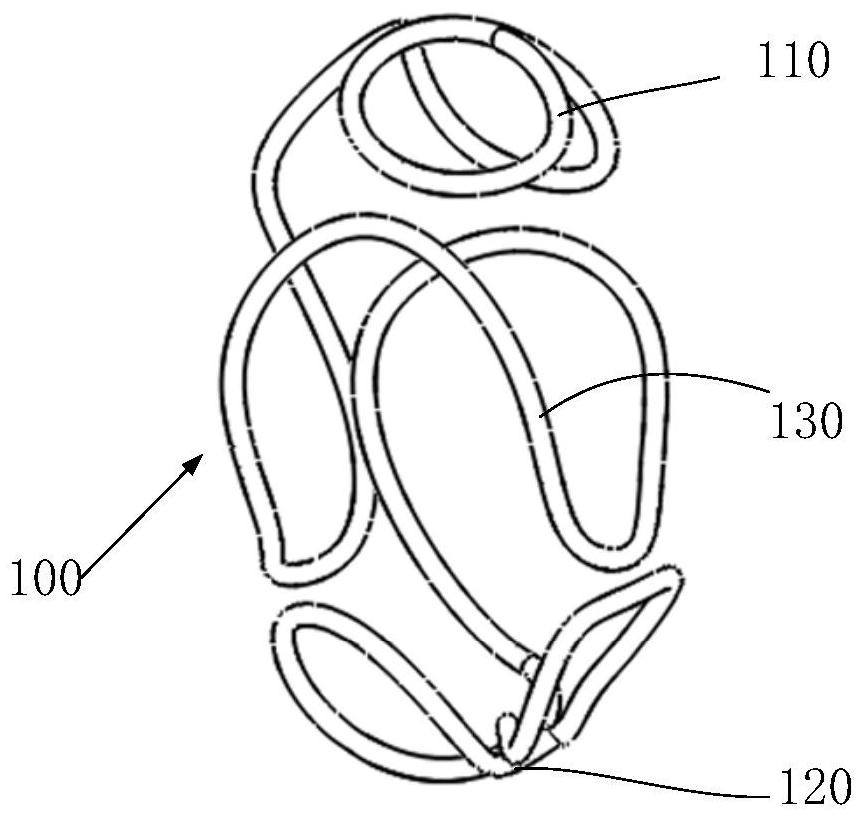

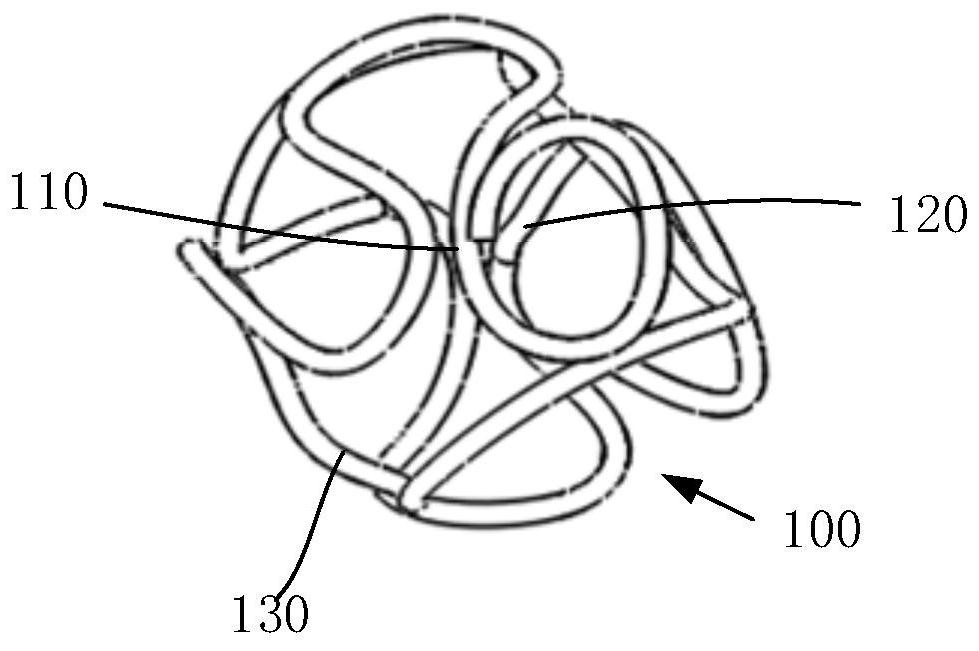

[0062] First, a metal wire with a diameter of 0.5 mm to 2 mm is helically wound along a mandrel to form a cylindrical helical spring structure, and then the mandrel is pulled away to obtain a primary coil 10 (such as Figure 4 shown).

[0063] Next, a mold 20 is provided, and the mold 20 includes a main body 21 and a boss 22 . In this embodiment, the main body 21 includes a cylinder 21a and a first hemisphere 21b and a second hemisphere 21c respectively disposed at two ends of the cylinder 21a. The cross-section of the protruding posts 22 is circular, and the number of the protruding posts 22 is ten, wherein three of the protruding posts 22 are evenly arranged around the axis of the first hemispherical body 21b, and four of the protruding posts 22 are arranged uniformly around the axis of the first hemisphere 21b. Columns 22 are evenly arranged around the axis of the cylinder 21a, and the remaining three convex columns 22 are evenly arranged around the axis of the second hemisp...

Embodiment 2

[0070] The difference between this embodiment and the first embodiment lies in that the number and arrangement of the protrusions 22 on the mold 20 are different. Specifically, please refer to Figure 11 , the mold 20 includes sixteen bosses 22, three of which are evenly arranged around the axis of the first hemisphere 21b, and three of the bosses 22 are arranged around the axis of the second hemisphere The axes of 21c are evenly arranged, and the remaining ten bosses 22 are divided into a first boss group and a second boss group, each group including five bosses 22 . The first protruding post group is close to the first hemispherical body 21b, and the five protruding posts 22 in this group are uniformly arranged around the circumference of the cylinder 21a. The second protruding post group is close to the second hemispherical body 21c, and the five protruding posts 22 in this group are uniformly arranged around the circumference of the cylinder 21a. In the circumferential d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com