Radial-flow secondary sedimentation device and sludge regeneration method

A radial flow and sludge technology, applied in the adjustment method of biological treatment, the feeding/discharging device of the settling tank, the separation method, etc., can solve the problems of increased construction costs, save land costs, and reduce equipment purchases And, the effect of reducing the return flow of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

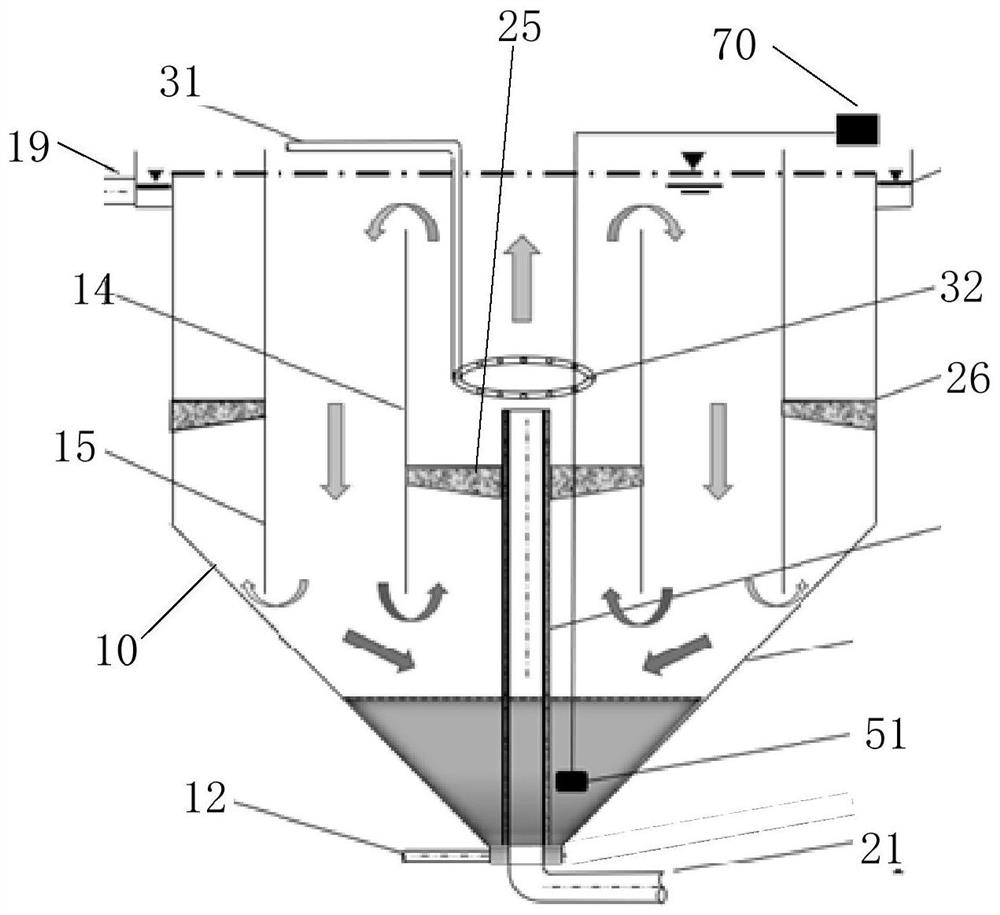

[0035] refer to figure 1 , the present invention proposes a radial flow secondary settling device, comprising a tank body 10, an inner cylinder 14, an outer cylinder 15, and a water inlet pipe 21; the upper end of the tank body 10 is open, and the lower end is closed to form a slope for accumulating sludge ; the inner cylinder 14 is arranged in the tank body 10, and is vertically connected, and the inside of the inner cylinder 14 forms an aeration area; the outer cylinder 15 is arranged on the outer periphery of the inner cylinder 14, and the outer cylinder 15 and the inner cylinder The area between the cylinders 14 forms a circulation area, and the area between the outer cylinder 15 and the tank body 10 forms a drainage area; the water inlet pipe 21 is arranged in the tank body 10; the aeration assembly is arranged in the Aeration zone.

[0036] Specifically, the water inlet pipe 21 extends upwards from the lower part of the tank body 10 to the aeration area, and the outer p...

Embodiment 2

[0040] refer to figure 1 The radial flow secondary sedimentation device also includes an aeration assembly, the aeration assembly includes an aeration element 32 arranged in the aeration area and an air inlet pipe 31 communicated with the aeration element 32, the aeration element 32 Air holes are arranged on it. The air inlet pipe 31 is inserted into the aeration area from the upper end of the tank body 10, and the aeration element 32 is an annular pipe or a spiral pipe. The aeration element 32 is located above the water outlet of the water inlet pipe 21, and is generally arranged in the middle and lower half of the aeration area.

[0041] In this embodiment, the sewage with sludge is input into the tank body 10, and the aeration component blows air in the aeration zone, and the generated air bubbles make the sewage rise and enter the upper part of the circulation zone; The circulation area sinks to the bottom of the tank body 10 and is drawn out from the sewage outlet at th...

Embodiment 3

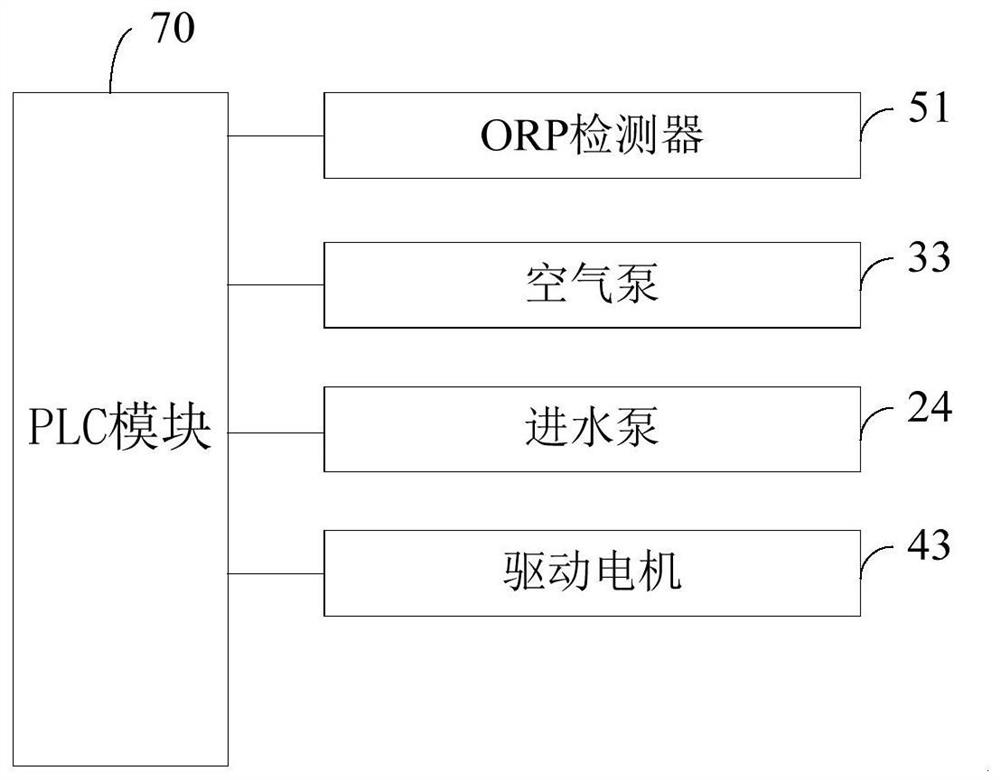

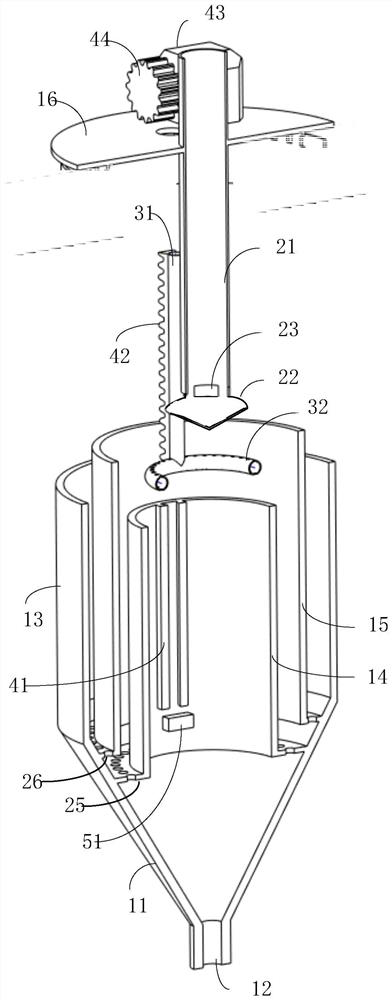

[0045] refer to figure 2 with image 3 , the present invention proposes a radial flow secondary sedimentation device, including: PLC module 70, ORP detector 51, tank body, inner cylinder 14, outer cylinder 15, aeration assembly and water inlet pipe 21, first lifting assembly and water inlet pipe twenty one. The lower end of the tank body 1 is closed to form a dirt collecting bucket 11, and the outer wall of the tank body is cylindrical. The inner cylinder 14 is also cylindrical, forming an aeration zone inside the inner cylinder 14; the outer cylinder 15 is cylindrical, extending upward from the inner wall of the sewage collection bucket 11, and is located between the outer shell 13 and the inner cylinder. 14, the outer cylinder 15 is higher than the inner cylinder 14; the cover 16 is arranged on the outer cylinder 15; the settling hole is arranged at the bottom of the inner cylinder 14 and the outer cylinder 15; the inner cylinder 14 and the outer cylinder 15 The area bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com