Bi2O3/(BiO)2CO3 heterojunction semiconductor photocatalyst and preparation method thereof

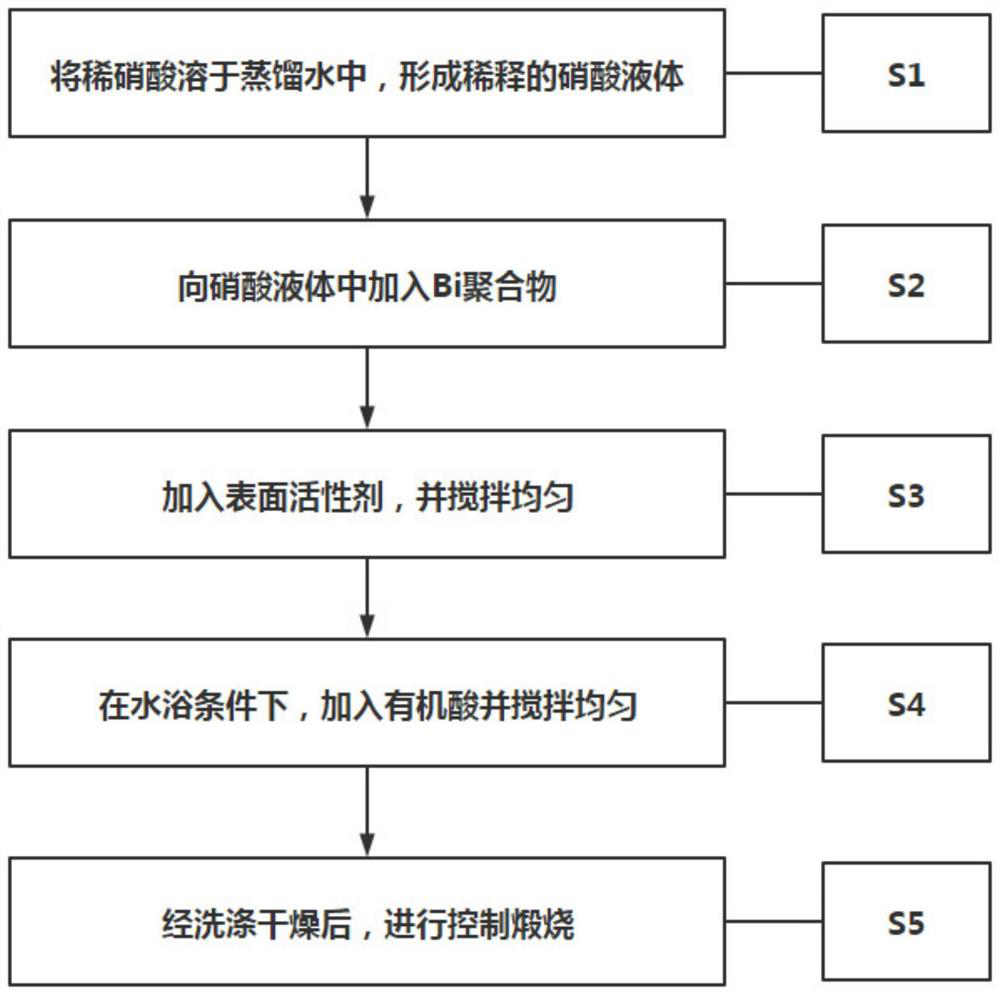

A photocatalyst and heterojunction technology, used in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve problems such as insufficient stability and poor photocatalytic performance, and achieve changes in charge transport methods and efficiency. , Improve the activity and stability, and promote the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0044] The difference between the preparation method of Example 2 and Example 1 is the S5 step:

[0045] S5. The mixture C was centrifuged to obtain the precursor powder, washed with ethanol and deionized water for 3 times, then dried at 80°C for 8 hours, and then calcined with air at 200°C for 2 hours in a muffle furnace, with a heating rate of 5°C / min, keep warm for 5 hours and then cool to room temperature to obtain a powder sample.

Embodiment 3

[0046] The difference between the preparation method of embodiment 3 and embodiment 1 is that step S5:

[0047] S5. Centrifuge the mixture C to obtain the precursor powder, then wash with ethanol and deionized water for 3 times, then dry at 80°C for 8 hours, and then use a muffle furnace to calcine in air at 350°C for 2 hours, and the heating rate is 5°C / min, keep warm for 5 hours and then cool to room temperature to obtain a powder sample.

Embodiment 1

[0070] In Example 10, after increasing the quality parameter of the surfactant, the addition of organic acid was reduced. The experimental data showed that the NO degradation efficiency of its product was different from that of Example 1, but it remained better overall; and In Example 11, the addition of surfactants was reduced, and after adjusting the composition of the organic acid and adding a sufficient amount of the organic acid, the resulting product still maintained a relatively good effect on the NO degradation efficiency.

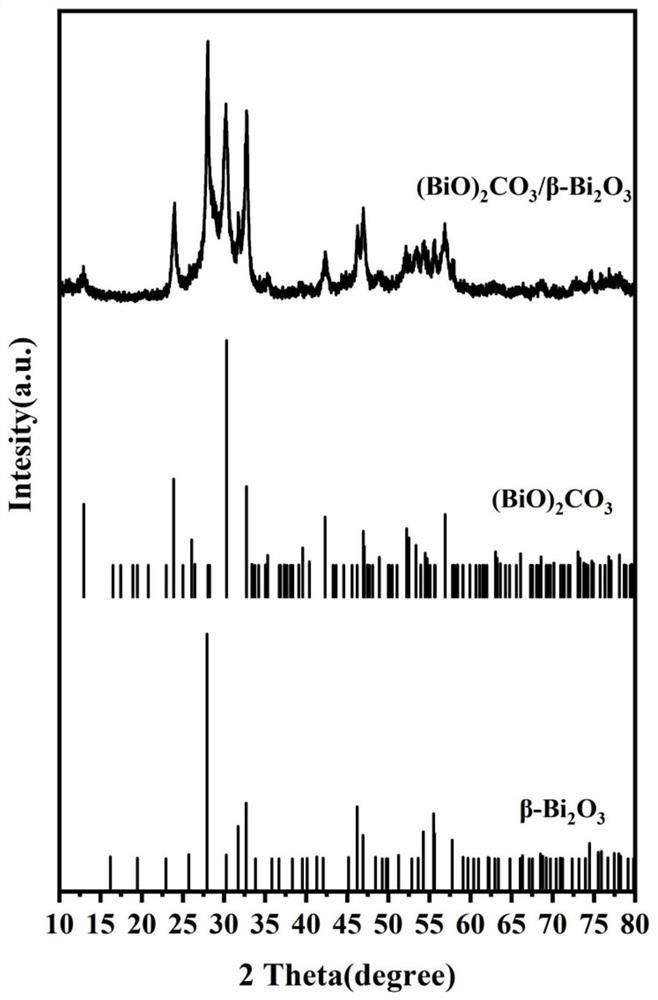

[0071] At the same time, according to the lack of surfactant addition in Comparative Example 1, the product lacks a sufficient amount of carbon element during synthesis, resulting in only part of the material generating Bi 2 o 3 / (BiO) 2 CO 3 , driving its overall poor stability, the experimental results are consistent with the pure phase β-Bi 2 o 3 relatively close.

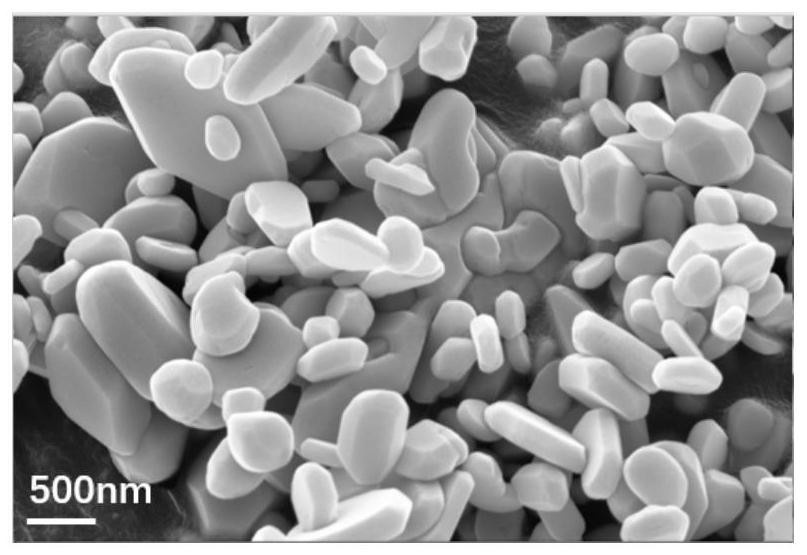

[0072] In summary, the present invention develops a kind of one-time effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com