Ammonia decomposition catalyst and preparation method and application thereof

A catalyst and ammonia decomposition technology, applied in the field of ammonia decomposition, can solve the problems of low low-temperature catalytic activity of the catalyst, poor ammonia decomposition effect, complicated preparation process, etc., and achieve small particle size, inhibition of sintering growth, and good particle dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

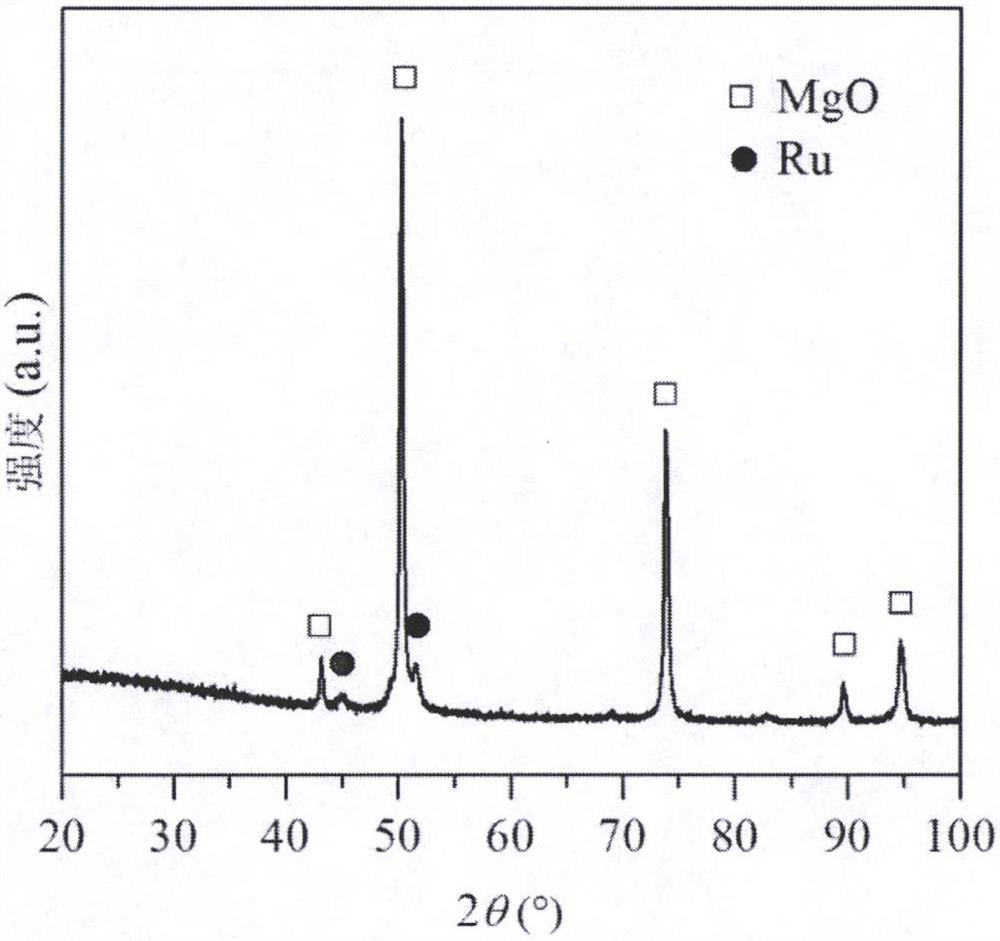

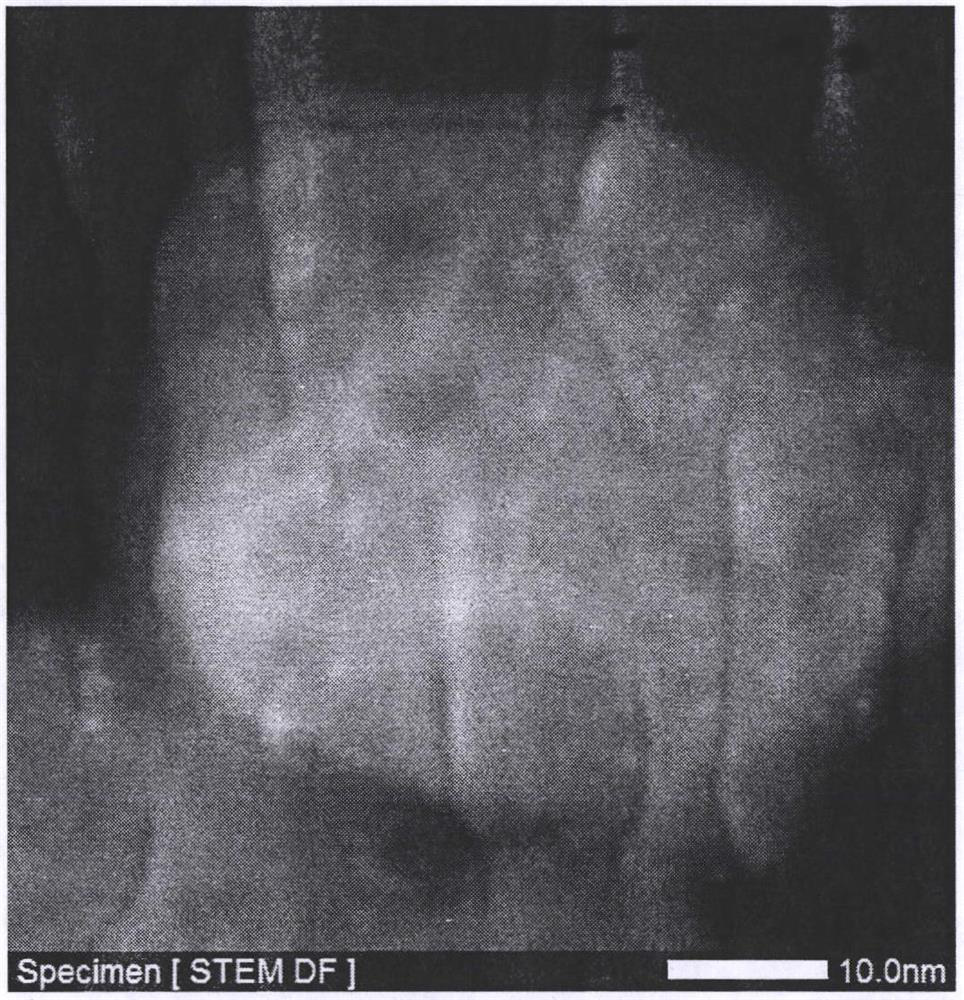

[0054] The present embodiment provides a kind of preparation method of ammonia decomposition catalyst, comprises the following steps:

[0055] 1) Put 0.1115g of ruthenium acetate, 4.8758g of magnesium acetate and 0.0351g of potassium acetate in a 250mL agate ball mill jar, and the mass ratio of the total weight of ruthenium acetate, magnesium acetate and potassium acetate to the agate pellets is 1:15 Put agate balls into it, and carry out ball milling in a planetary ball mill, the ball milling speed is 800r / min, and the ball milling time is 2h, to obtain metal salt mixture powder;

[0056] 2) The metal salt mixture powder obtained in step 1) is placed in a muffle furnace for calcination under an air atmosphere, the calcination temperature is 500° C., and the calcination time is 5 hours. After the calcination is completed, the mixture obtained after calcination is Powder is carried out tabletting, crushing, sieving, obtains granular mixture (the particle diameter of granular mi...

Embodiment 2

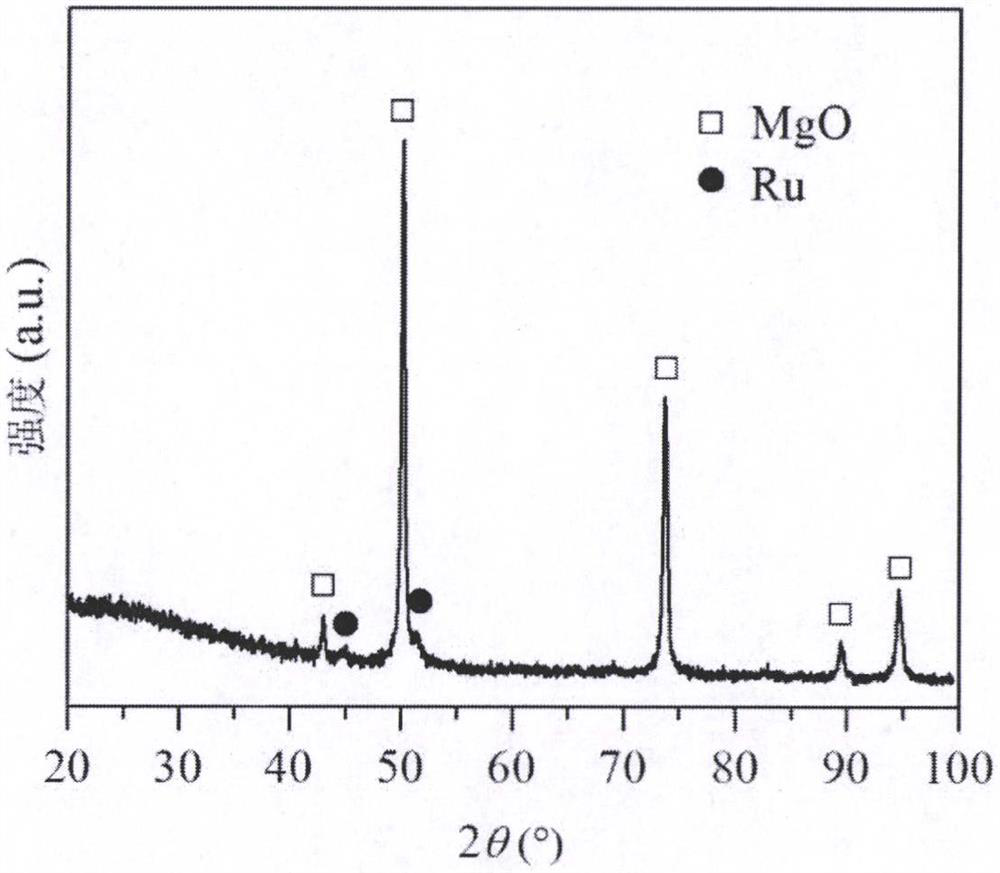

[0061] The present embodiment provides a kind of preparation method of ammonia decomposition catalyst, comprises the following steps:

[0062] 1) 0.1115g ruthenium acetate, 4.8758g magnesium acetate and 0.0702g potassium acetate are placed in a 250mL agate ball mill jar, and the mass ratio of ruthenium acetate, magnesium acetate, potassium acetate to the mass ratio of agate pellets is 1:15 Put agate balls into it, and carry out ball milling in a planetary ball mill, the ball milling speed is 800r / min, and the ball milling time is 2h, to obtain metal salt mixture powder;

[0063] 2) The metal salt mixture powder obtained in step 1) is placed in a muffle furnace for calcination under an air atmosphere, the calcination temperature is 500° C., and the calcination time is 5 hours. After the calcination is completed, the mixture obtained after calcination is Powder is carried out tabletting, crushing, sieving, obtains granular mixture (the particle diameter of granular mixture is 50...

Embodiment 3

[0068] The present embodiment provides a kind of preparation method of ammonia decomposition catalyst, comprises the following steps:

[0069] 1) 0.1859g ruthenium acetate, 4.8758g magnesium acetate and 0.0585g potassium acetate are placed in a 250mL agate ball mill jar, and the mass ratio of ruthenium acetate, magnesium acetate, potassium acetate to the mass ratio of agate pellets is 1:15 Put agate balls into it, and carry out ball milling in a planetary ball mill, the ball milling speed is 800r / min, and the ball milling time is 2h, to obtain metal salt mixture powder;

[0070] 2) The metal salt mixture powder obtained in step 1) is placed in a muffle furnace for calcination under an air atmosphere, the calcination temperature is 500° C., and the calcination time is 5 hours. After the calcination is completed, the mixture obtained after calcination is The powder is tabletted, crushed and sieved to obtain a granular mixture (the particle diameter of the granular mixture is 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com