Spraying method for metal end of steel-plastic adapter

A technology of steel-plastic conversion joints and metal ends, which is applied in the direction of pipes/pipe joints/fittings, coatings, and devices for coating liquid on the surface, which can solve the problems of metal end coating adhesion, unstable cathode stripping pass rate, and metal Rust on the surface of the tube, discontinuous production, etc., to achieve the effect of improving cathodic stripping ability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

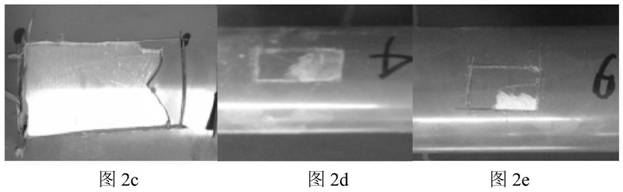

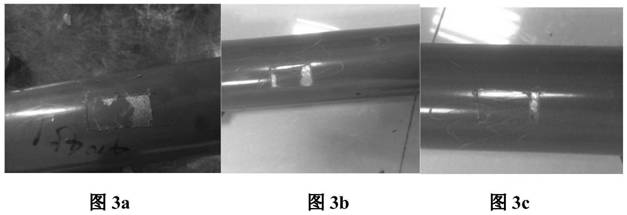

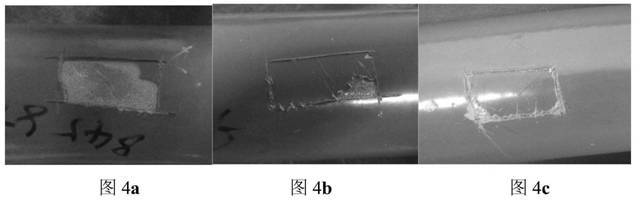

[0042] figure 1 It is a schematic process flow chart of the spraying method for the metal end of the steel-plastic conversion joint according to an embodiment of the present application. This embodiment provides a method for spraying the metal end of the steel-plastic conversion joint, which is carried out according to the following steps:

[0043] Step 100 Sandblasting pretreatment: use an automatic rotary sandblasting machine, select steel shots with a hardness of 40-50HRC, and a particle size of 0.6-1.0mm; : Mix in a ratio of 6, and then sandblast the surface of the metal pipe at the metal end. The cleanliness of the treatment is Sa2.5, and the depth of the anchor pattern is 60-90 microns, so as to remove the rust on the metal end.

[0044] Step 200 Online spray degreasing treatment of the metal end: first, spray and pre-degrease the surface of the metal pipe on the hanging metal end, and mix the degreasing agent and water in the spray pre-degreasing according to the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com