A kind of logistics waste paper recovery device and recovery method for modern logistics field

A modern logistics and recycling device technology, applied in manufacturing tools, presses, metal processing, etc., can solve the problems of large volume, easy scattering, and gaps in waste paper bags, and achieve the effect of improving recycling efficiency, avoiding scattering, and facilitating transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

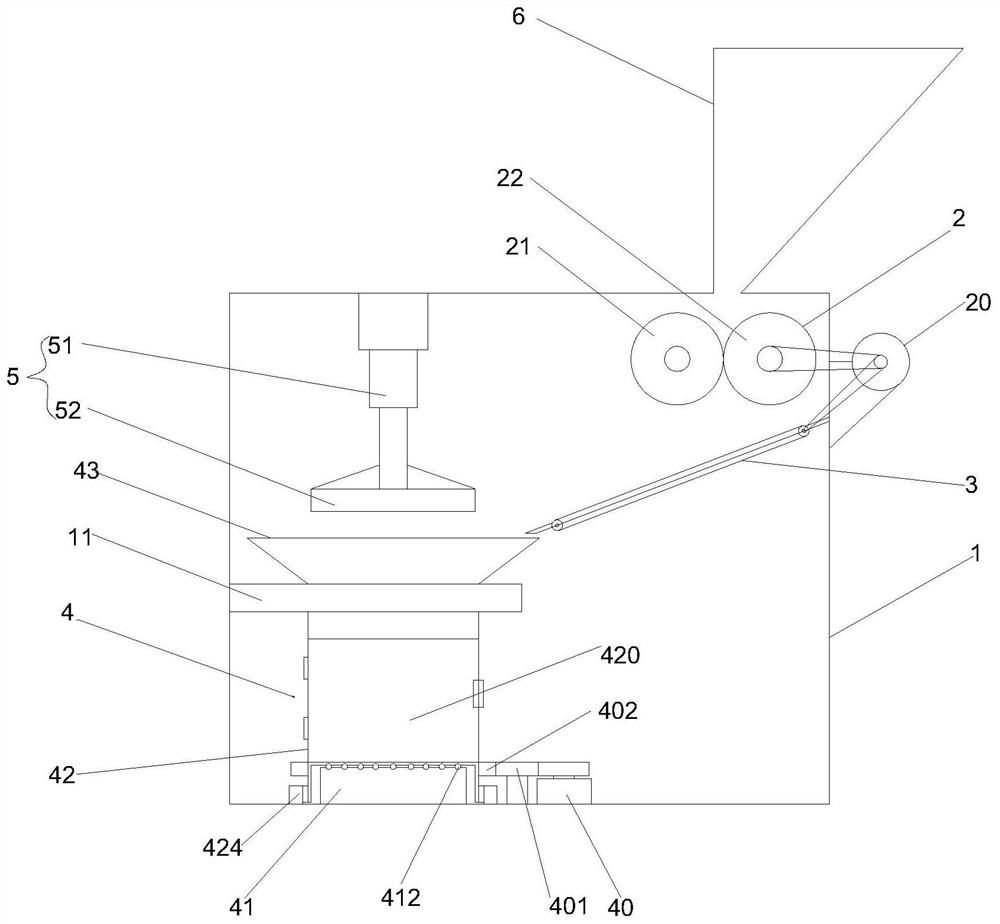

[0042] A logistics waste paper recycling device used in the field of modern logistics, see Figures 1~3 As shown, including a pressing device 4, the pressing device 4 includes:

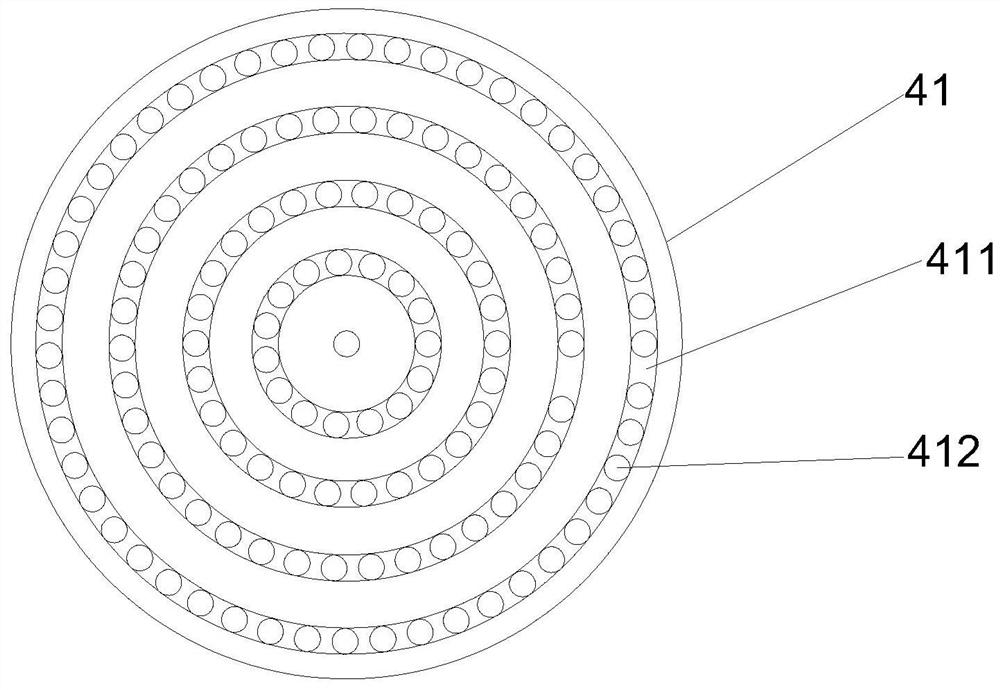

[0043] base 41;

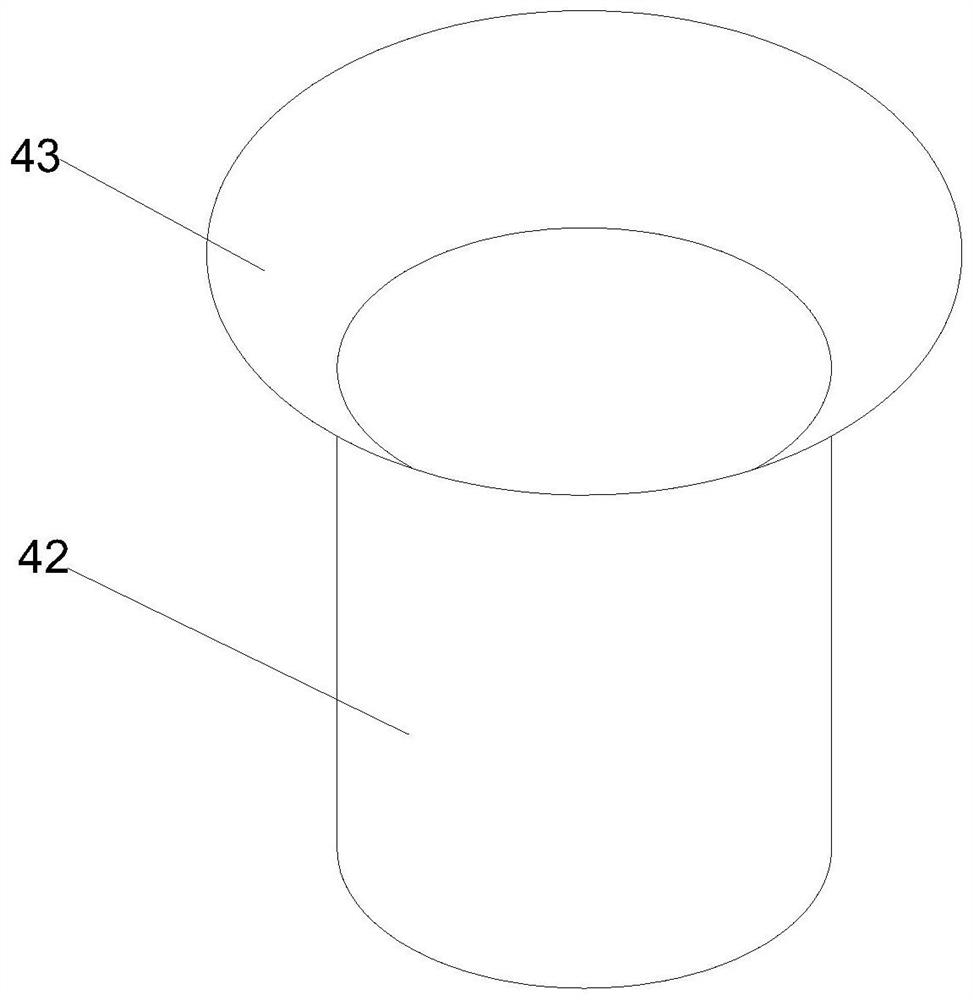

[0044] The first cylinder 42 is vertically arranged on the base 41, the bottom of which is rotatably connected to the base 41, and the top is set to be open; the side wall of the first cylinder 42 is also provided with an arc-shaped cover 420 that can be opened and closed. , the arc length of the section of the arc cover 420 is greater than or equal to half of the perimeter of the section of the first cylinder 42;

[0045] The suppression mechanism 5 is arranged above the first cylinder 42. The suppression mechanism 5 includes a circular pressing plate 52 horizontally arranged just above the first cylinder 42, and its radius is smaller than the inner diameter of the first cylinder 42; It is arranged on the top surface of the circular pressure plate, and is used to push the circular...

Embodiment 2

[0054] A logistics waste paper recovery device used in the field of modern logistics, see Figures 1~4 As shown, on the basis provided in Embodiment 1, the device further includes

[0055] Slitting mechanism 2;

[0056] The slitting mechanism 2 includes: a first paper cutting roller 21 and a second paper cutting roller 22 arranged in parallel;

[0057] A plurality of annular first paper cutting knives 211 are fixedly sleeved on the first paper cutting roller 21 at equal intervals;

[0058] The second paper cutting roller 22 is fixedly sleeved with a plurality of annular second paper cutting knives 221 at equal intervals;

[0059] Each first paper cutter 211 corresponds to each second paper cutter 221 one-to-one, and abuts each other;

[0060] The conveyor belt 3 is arranged between the slitting mechanism 2 and the conical cylinder 43, one end of the conveyor belt 3 is placed under the first paper cutting roller 21 and the second paper cutting roller 22, and the other end ex...

Embodiment 3

[0068] A logistics waste paper recovery device used in the field of modern logistics, see Figures 1~5 As shown, on the basis of Example 1, in order to facilitate the removal of the pressed waste paper ingot from the first cylinder, the inner wall of the first cylinder 42 is opened on the part opposite to the arc-shaped cover 420 from bottom to top There are a plurality of transverse arc-shaped through grooves 421, each arc-shaped through groove 421 is provided with an arc-shaped rod body 422, and the upper and lower sides of one end of each arc-shaped rod body 422 are rotatably connected with the upper and lower sides of the end of the arc-shaped through groove 421. ; The other end extends along the arc-shaped through groove 421 to the first cylindrical body 42 and the arc-shaped cover body 420 is buckled to form a traction end,

[0069] Each pulling end is connected with a connecting rod, one end of each connecting rod is connected with the pulling end, and the other end ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com