Stacking maintenance frame for concrete blocks and using method of stacking maintenance frame

A technology of concrete blocks and curing frames, which is applied in the direction of ceramic molding machines and manufacturing tools, which can solve the problems of staff exerting great force, causing safety accidents, and corrosion of electric devices, so as to increase the protection effect and reduce maintenance Cost, Erosion Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

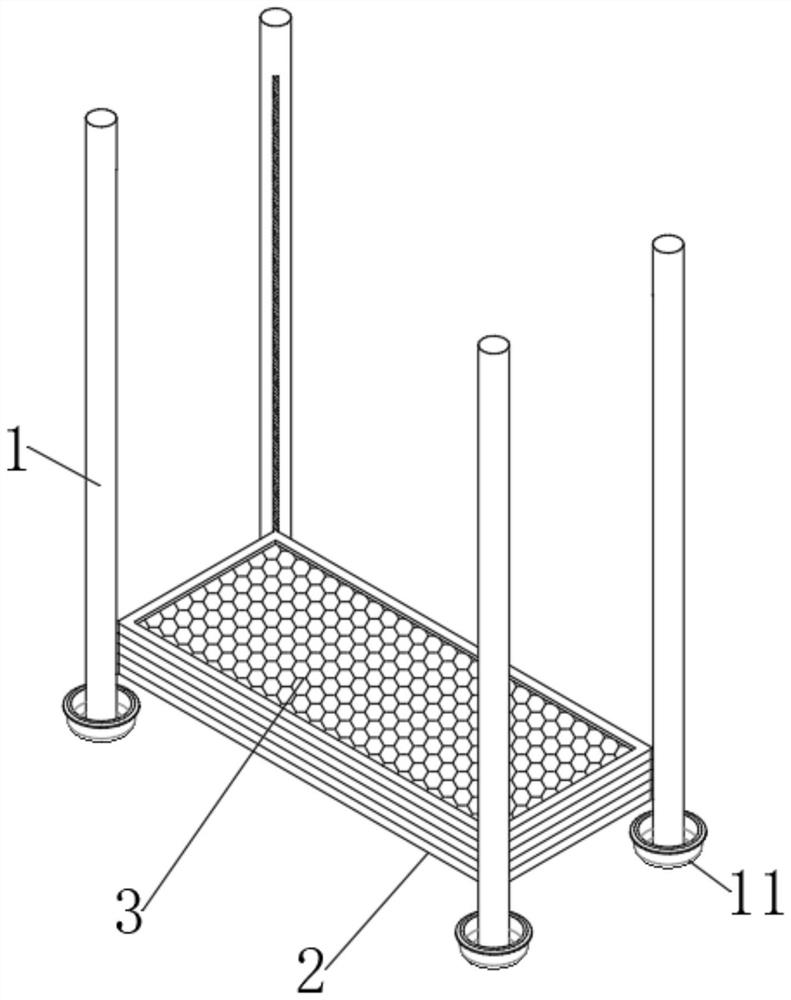

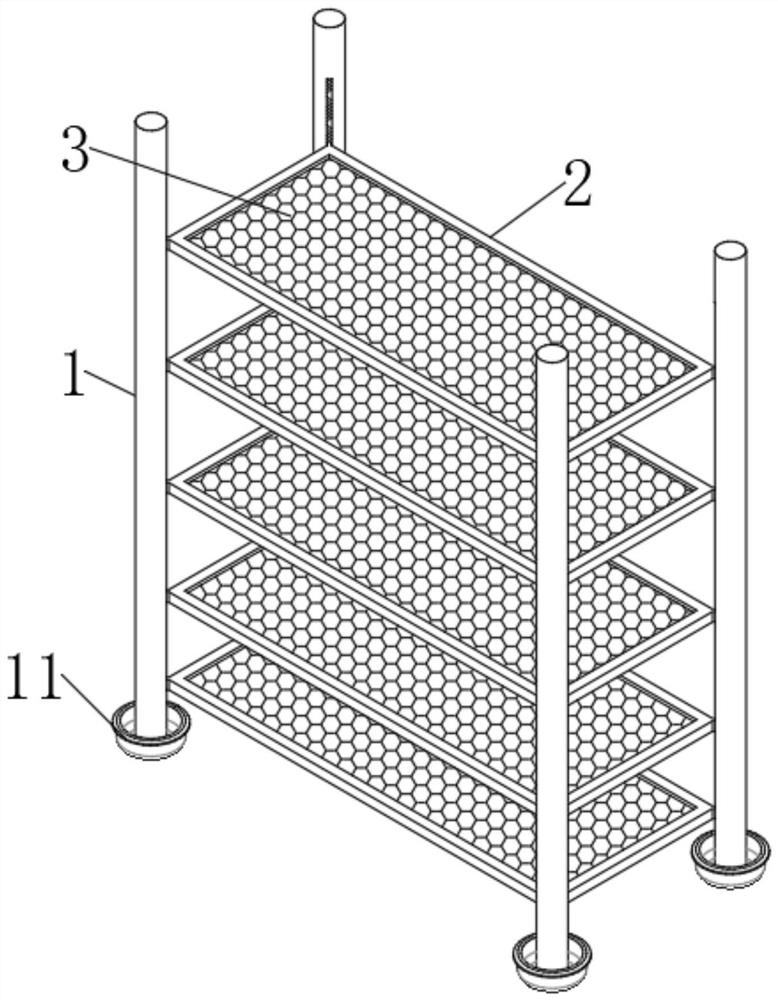

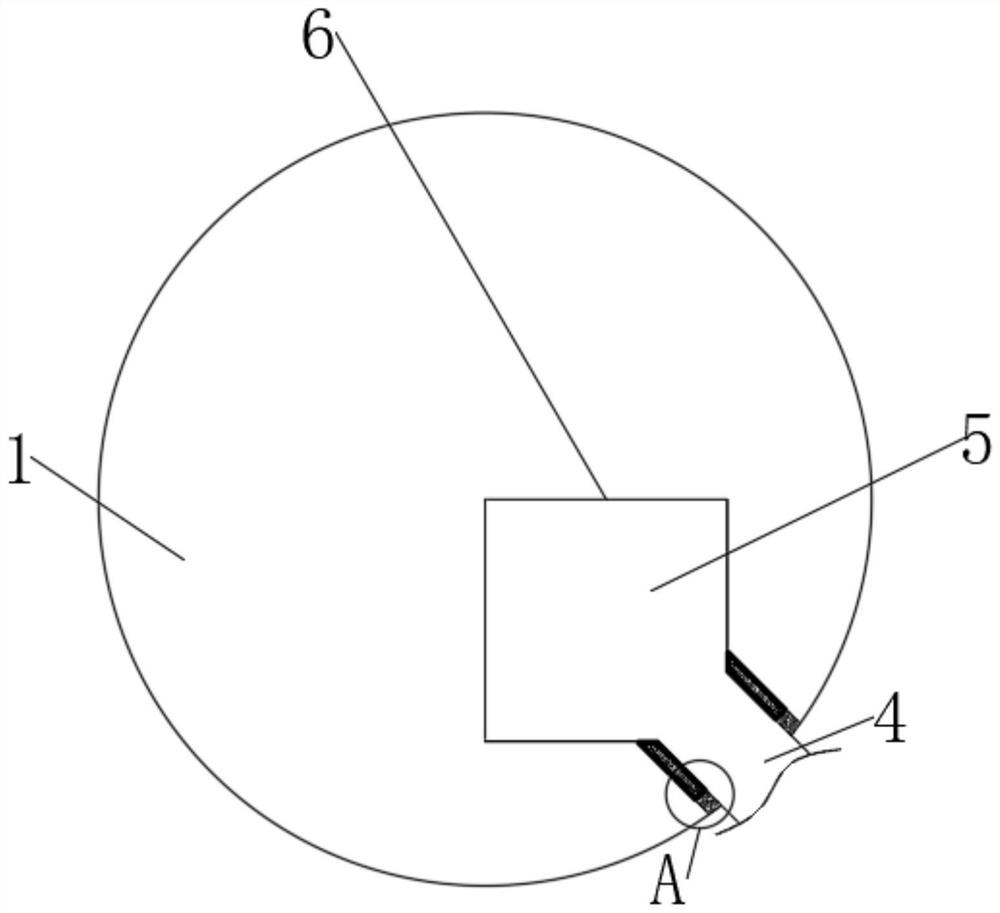

[0039] see figure 1 and 3 -6, a laminated curing frame for concrete blocks, including four pillars 1 and a placement frame, the placement frame is located in the middle of the quadrilateral formed by the four pillars 1, the placement frame includes a placement frame 2, and the placement frame 2 is inlaid and installed There is a placement net 3, and a plurality of pillars 1 near the side of the placement frame are excavated with electromagnetic slide rails 6 and slide grooves 7. The slide groove 7 communicates with the electromagnetic slide rail 6 and the outside world, and the end of the placement frame near the pillar 1 is fixedly connected with the slide groove. 7 matching connecting column 4, the end of the connecting column 4 away from the placement frame is fixedly connected with the electromagnetic slider 5 matching the electromagnetic slide rail 6, and the two side walls of the sliding groove 7 are fixedly connected with the sealing rubber pad 8, Two sealing rubber pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com