Peelable hot melt adhesive for packaging electric appliances and preparation method thereof

A technology for hot melt adhesives and electrical appliances, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc. The effect of reducing impurities, reducing labor costs, and easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing a peelable hot-melt adhesive for electrical packaging, comprising the steps of:

[0056] S1: Confirm that the bottom valve of the reaction kettle is closed, turn on the steam heating, turn on the stirring paddle, and slowly add rubber oil and antioxidant;

[0057] S2: Raise the temperature of the reactor in S1 to 160-170°C, add the formulated amount of rubber polymer, and after the rubber polymer is completely added, scrape off the tank wall of the reactor and the rubber polymer on the stirring paddle with a scraper, After stirring for about 40 minutes, take a sample to see if the sample is completely melted. If the rubber polymer is not completely melted and there are still particles, then continue to stir, record and extend the stirring time until the rubber polymer particles are completely melted;

[0058] S3: After the polymer in S2 is completely melted, add the tackifying resin evenly and stir. After all th...

Embodiment 1-6 and comparative example 1

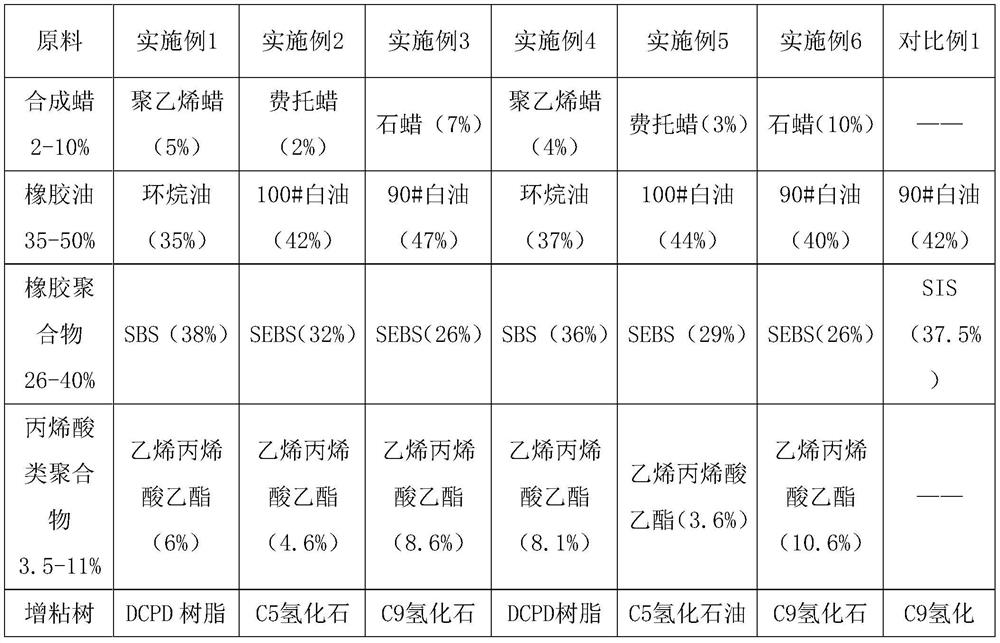

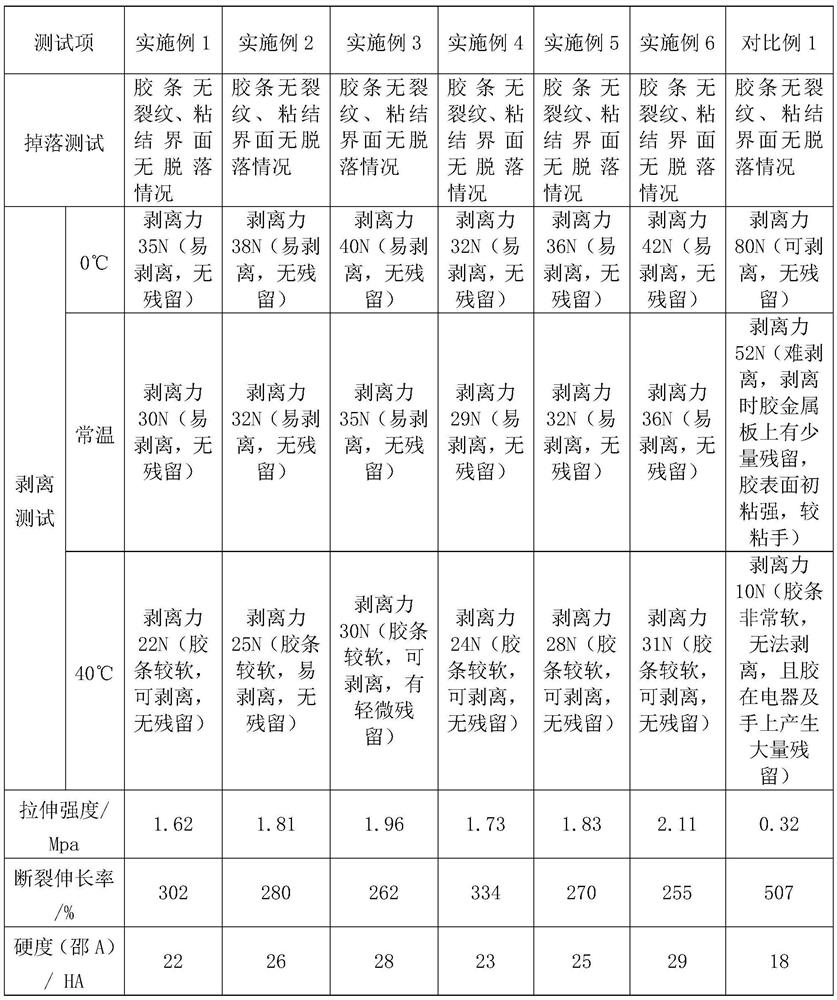

[0070] Weigh the raw materials according to the ratio in Table 1 respectively, and prepare the product according to the steps in Examples 1-6, see Table 1 for details:

[0071] Table 1 Embodiment 1-6 and comparative example 1 raw material ratio table

[0072]

[0073]

[0074] Wherein, unless otherwise specified in Table 1, in order to reflect the comparability of test results, the raw materials used are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com