Air energy expanded rock fracturing system and using method thereof

An air energy and fracturing technology, which is applied in earth drilling, offensive equipment, blasting barrels, etc., can solve problems such as excessive carbon dioxide in the workplace and suffocation of staff, and achieve low construction costs, no noise pollution, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

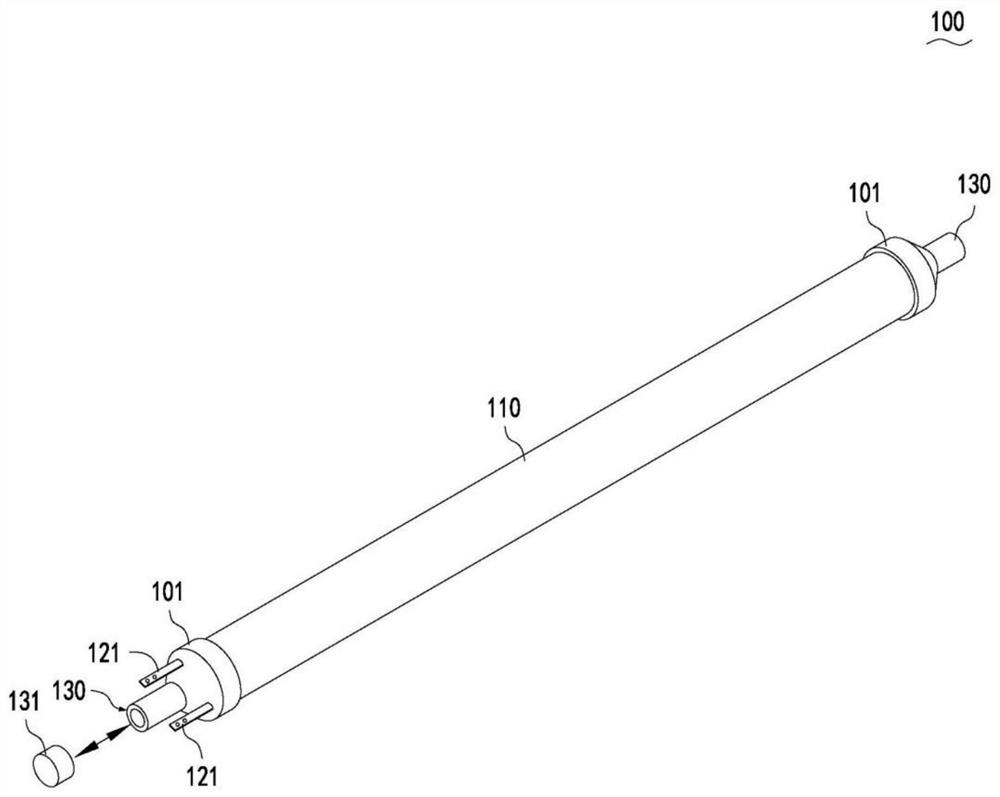

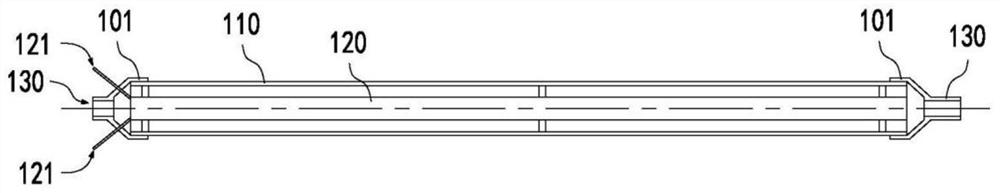

[0033] Such as Figure 1 to Figure 4 As shown, an air-expandable rock fracturing system according to a preferred embodiment of the present invention is used to fracturing rock through an air medium.

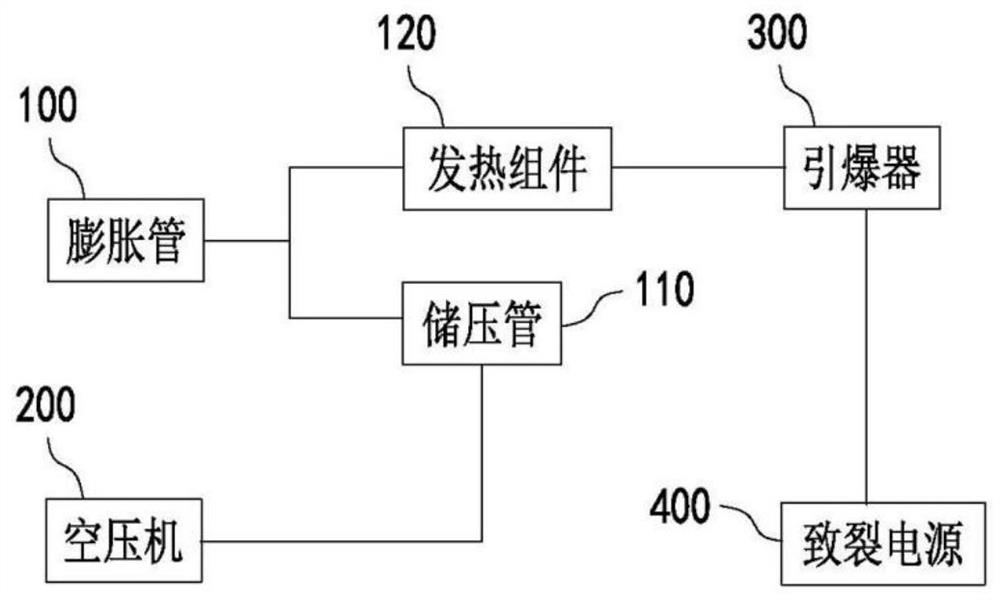

[0034] Based on the above technical solution, this embodiment provides an air energy expandable rock fracturing system, including an expansion tube 100, an air compressor 200, a detonator 300, and a fracturing power supply 400. The expansion tube 100 includes a pressure storage tube 110, a heating component 120 , the expansion tube 100 seals the heating component 120 inside, the air compressor 200 can be connected to the pressure storage tube 110 through a pipeline, and the heating component 120 can be connected to the cracking power supply 400 through the detonator 300 .

[0035] Wherein, the expansion tube 100 is a direct working component of expansion fracturing. The heating component 120 is used for heating and pressurizing the expansion tube 100 in the expansion tube 100 , ...

Embodiment 2

[0049] The general working sequence of the steps used for the fracturing system in Example 1 is: drilling holes at the construction site—assembling the expansion pipe—installing expansion—blocking with special cement—pressurizing high-pressure gas during expansion—expanding - Clean up the working surface.

[0050] Specifically, such as Figure 5 As shown, the present invention provides a method for using an air-expandable rock fracturing system, comprising the following steps:

[0051] S100. Drill holes on the rock and clean them, place expansion tubes 100 in the holes and seal the holes with quick-drying cement until the cement reaches the solidification strength. Here, the drilling depth has nothing to do with the rock grade, but is determined by the geographical environment; the drilling size has nothing to do with the rock grade, and only the expansion tube can be placed; there is no need to drain the water, and the requirements for the rock hole are not high. Therefore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com