Preparation method of Co2Z type ferrite sintered sheet

A technology of ferrite and sintered sheets, applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., to meet the application requirements, good magnetic properties, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

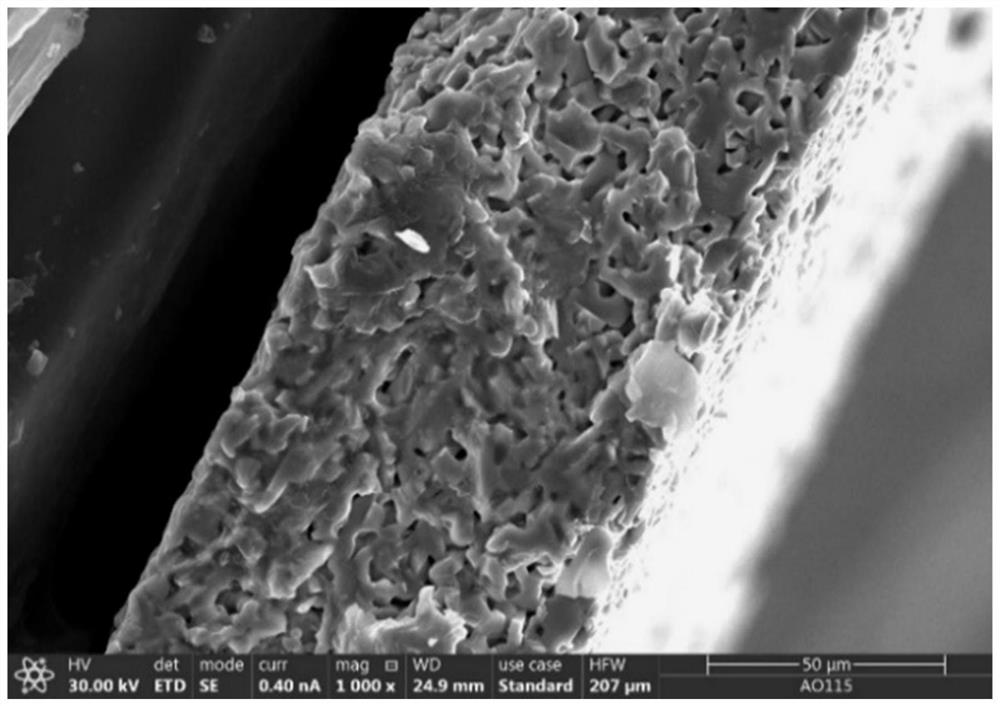

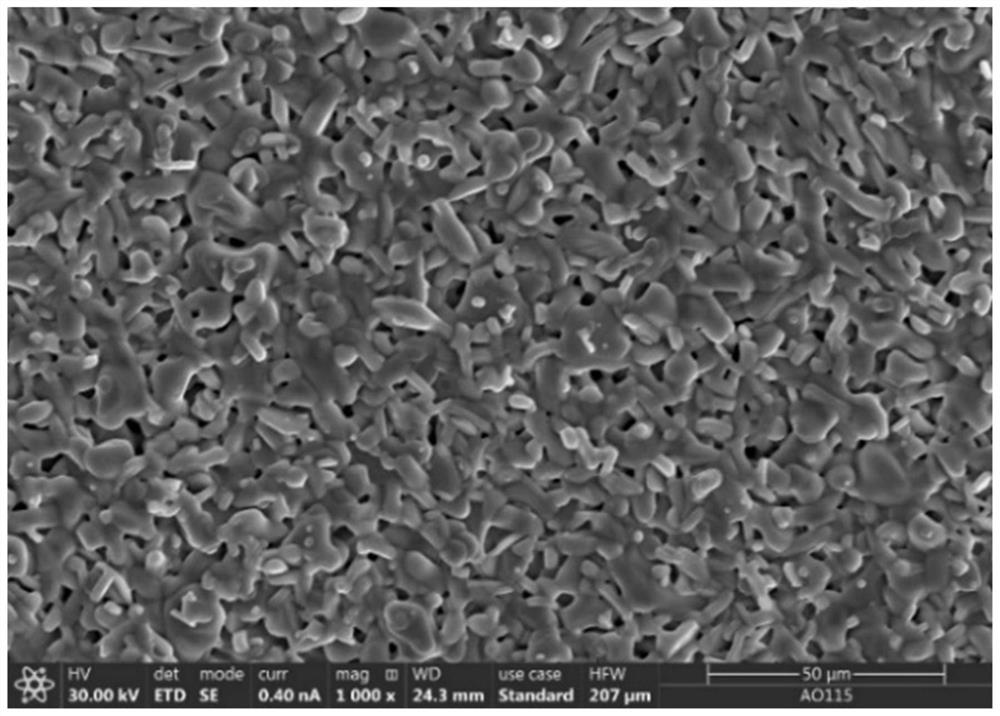

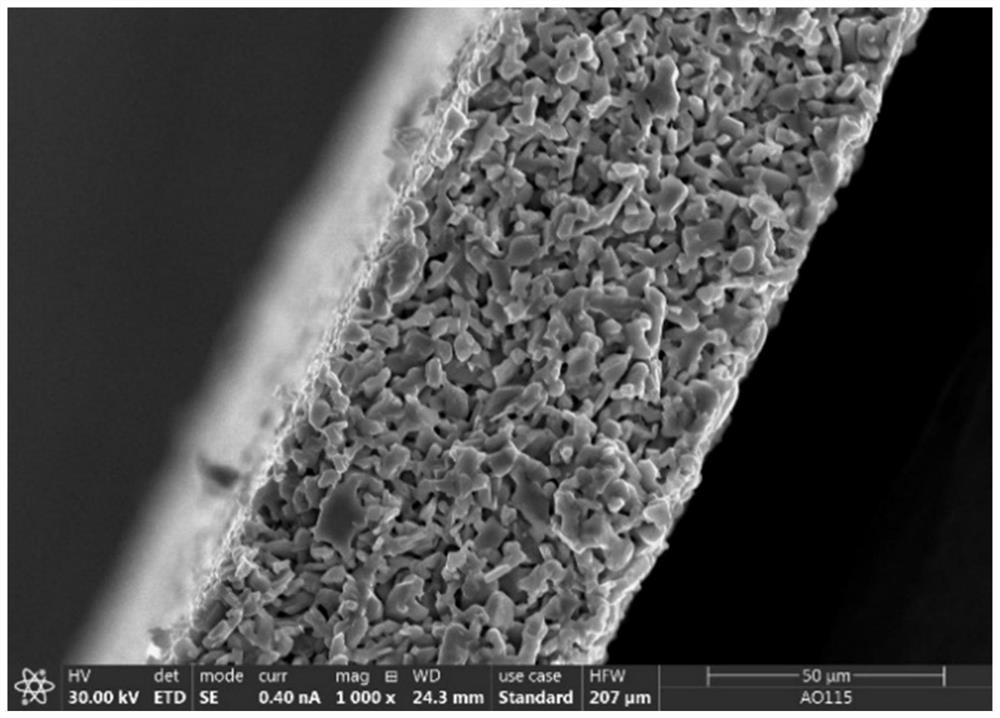

Image

Examples

Embodiment 1

[0064] In this case Co 2 The preparation method of Z-type ferrite sintered sheet is as follows:

[0065] Preparation of powder: the raw material is analytically pure BaCO 3 , SrCO 3 , Fe 2 o 3 、Co 3 o 4 , the ratio is according to Ba 1.5 Sr 1.5 co 2 Fe 21.6 o 41 For calculation, the raw materials are first dried in an oven for 10 hours at a drying temperature of 120°C. The proportioning is carried out according to the above ingredients, and then put into a ball mill tank for ball milling. The balls are steel balls (the ratio of material to ball is 1:10 , the ball milling medium is water, and the ratio of mass to raw material is 1:1).

[0066] Put the ball-milled powder into an oven for drying at a drying temperature of 120°C. After drying, put the powder into an alumina crucible and put it into a high-temperature furnace for sintering. The sintering temperature is 1300°C and the sintering time is 4 Hours, the heating rate was 5°C / min.

[0067] After sintering, the...

Embodiment 2

[0071] In this case Co 2 The difference between the preparation method of the Z-type ferrite sintered sheet and that of Example 1 is that the second sintering in this example is held at a final sintering temperature of 1150° C. for 10 hours, and the rest are the same as in Example 1.

Embodiment 3

[0073] In this case Co 2 The difference between the preparation method of the Z-type ferrite sintered sheet and that of Example 1 is that the second sintering in this example is held at a final sintering temperature of 1150° C. for 5 hours, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com