Ceramic sintering method and ceramic

A sintering method and ceramic technology, applied in the field of ceramic material preparation, can solve the problems of complicated devices and steps, and achieve the effect of simple process and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

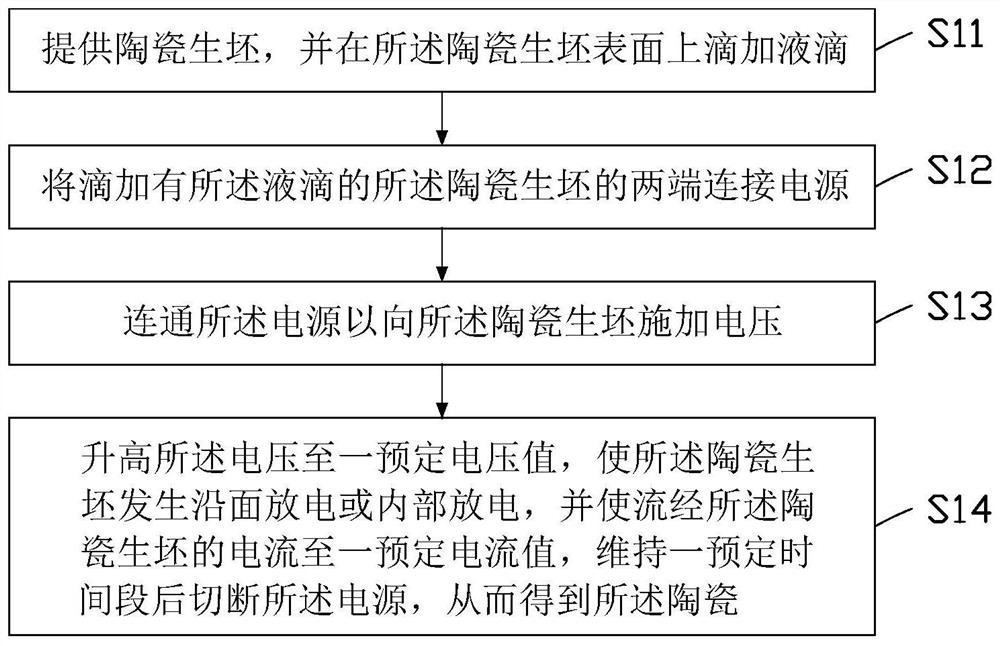

Method used

Image

Examples

Embodiment 1

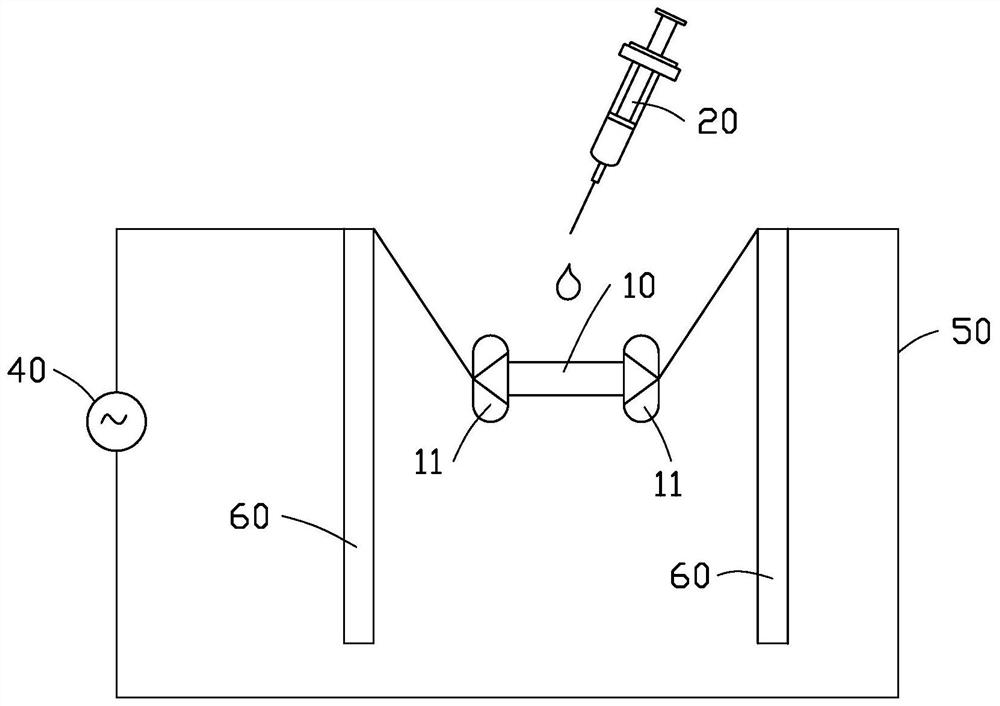

[0051] Step 1: Use a syringe to manually add 50 μL of water to a zinc oxide ceramic green body in the shape of a dog bone. Among them, the thickness of the middle part of the dog-bone shaped ceramic green body is 1.7mm, the length is 21mm, and the width is 3.3mm.

[0052] In the second step, wires are wound on both ends of the zinc ceramic green body, and the wires are connected to an AC power source, and the wires are fixed on a fixing bracket to suspend the ceramic green body.

[0053] The third step is to turn on the power supply, and then rapidly increase the voltage at a rate of 1kV / s until the voltage at both ends of the ceramic green body suddenly drops and the passing current rises suddenly, keep the voltage and current unchanged, and disconnect after 1 minute power supply, complete sintering.

Embodiment 2

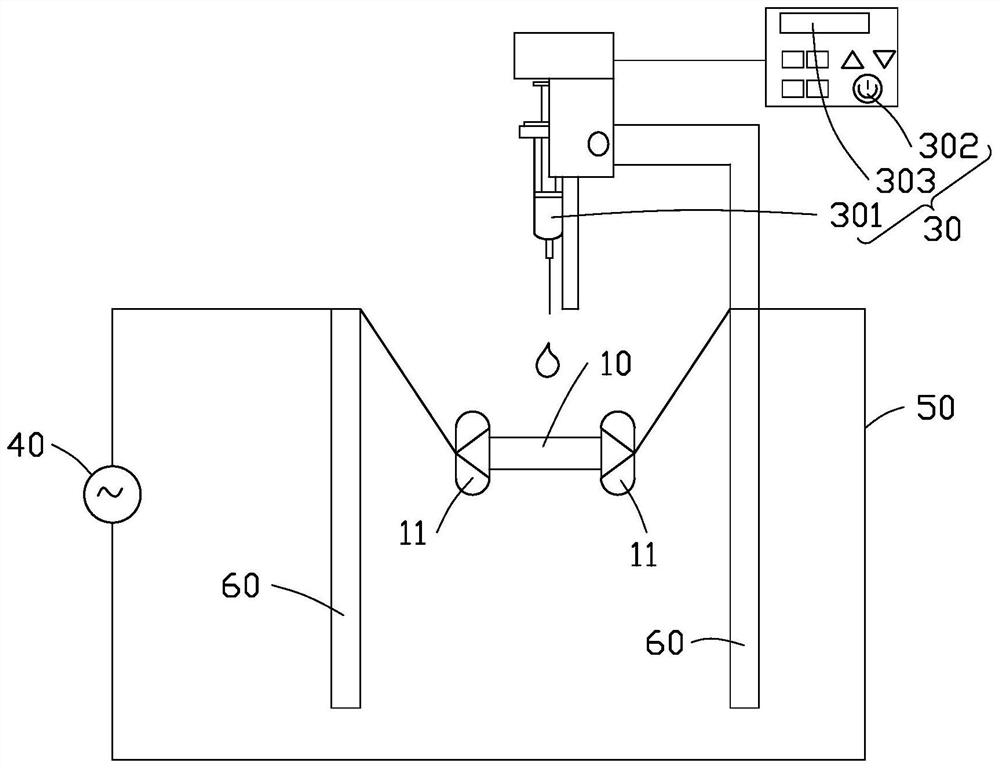

[0055] The difference from Example 1 is that in the first step, 100 μL of sodium chloride solution with a mass fraction of 20% is added dropwise at a flow rate of 5 μL / s using an automatic sampling device; the shape of the ceramic green body is a cylinder, and the diameter is 3mm and a length of 22mm. In the second step, connect to the DC power supply.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com