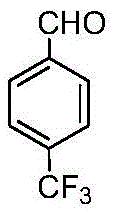

Method for preparing p-benzaldehyde

A technology of trifluoromethylbenzaldehyde and trifluoromethylbenzene is applied in the field of preparation of p-trifluoromethylbenzaldehyde, can solve the problems of harsh reaction conditions, unfriendly environment, and high cost of raw materials, and achieves easy post-processing, The effect of cheap raw materials, process flow and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

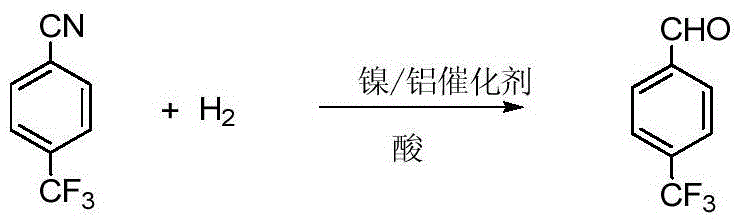

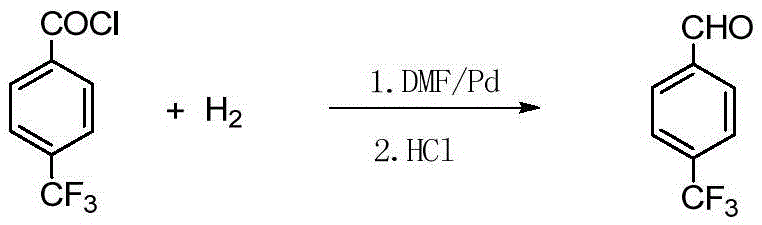

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 intermediate 1-nitromethyl-4-trifluoromethylbenzene

[0029] Put 18.0g (0.1mol) of p-chlorobenzotrifluoride and 20.2g (0.2mol) of triethylamine into a 250ml four-neck flask, stir and mix, cool down to -5°C, drop in 30.5g (0.5mol) of nitromethane, drop Bi heat preservation reaction 3h. Add 109.5g (0.3mol) of 10% hydrochloric acid solution after the reaction, extract and separate layers with 100mL toluene, filter, distill to obtain 20.7g1-nitromethyl-4-trifluoromethylbenzene, content 96.9% (liquid chromatography, external standard method).

Embodiment 2

[0030] The preparation of embodiment 2 intermediate 1-nitromethyl-4-trifluoromethylbenzene

[0031] Put 18.0g (0.1mol) of p-chlorobenzotrifluoride and 15.2g (0.15mol) of triethylamine into a 250ml four-neck flask, stir and mix, cool down to -5°C, drop in 12.2g (0.2mol) of nitromethane, drop Bi heat preservation reaction 2h. Add 109.5g (0.3mol) of 10% hydrochloric acid solution after completion of the reaction, extract the layers with 100mL toluene, filter, and distill to obtain 20.6g of 1-nitromethyl-4-trifluoromethylbenzene, with a content of 95.5% (liquid chromatography, external standard method).

Embodiment 3

[0032] The preparation of embodiment 3 intermediate 1-nitromethyl-4-trifluoromethylbenzene

[0033] Put 18.0g (0.1mol) of p-chlorobenzotrifluoride and 10.1g (0.1mol) of triethylamine into a 250ml four-necked flask, stir and mix, cool down to -5°C, drop in 12.2g (0.2mol) of nitromethane, drop Bi heat preservation reaction 2h. Add 109.5g (0.3mol) of 10% hydrochloric acid solution after the reaction, extract the layers with 100mL toluene, filter, and distill to obtain 20.6g of 1-nitromethyl-4-trifluoromethylbenzene, with a content of 95.4% (liquid chromatography, external standard method).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com