Differentiated array beam wavefront corrector preparation method based on aberration measurement

A technology of wavefront correctors and array beams, applied in optics, instruments, optical components, etc., can solve the problems of lack of design flexibility and no design of aberration characteristics of incident beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Glossary:

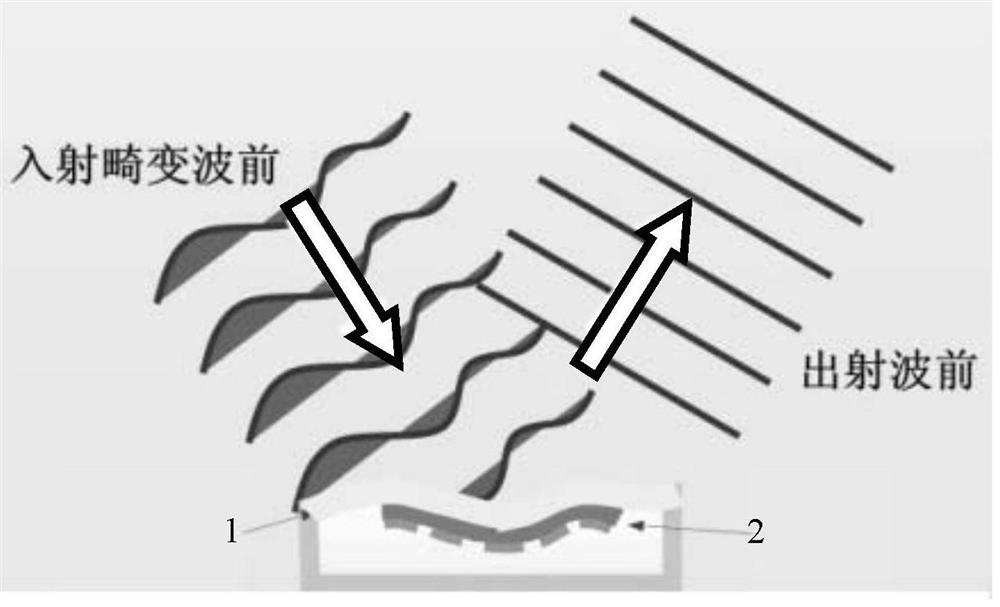

[0072] Corrector: It can produce surface shape changes according to the control signal, which is used to correct the wavefront phase distortion of the beam incident on its surface. Divided into tilting mirrors for correcting global oblique aberrations and deformable mirrors for correcting higher-order aberrations.

[0073] Deformable Mirror: A type of corrector used to correct higher order aberrations.

[0074] Driver: The active unit that performs deformation in the corrector, usually composed of piezoelectric ceramics, magnetostrictive materials, etc.

[0075] Electrode: A metal element that is connected to the driver and applies a voltage to the driver, usually in the form of a copper sheet or other metal mask.

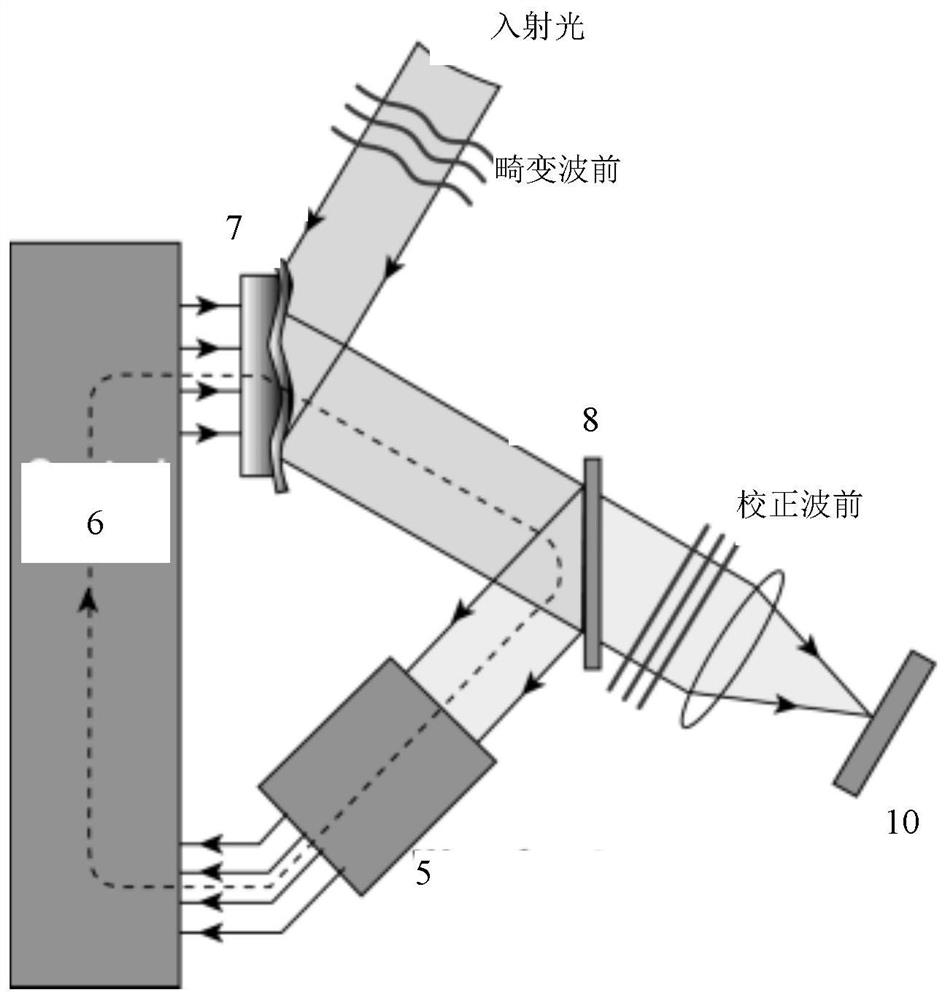

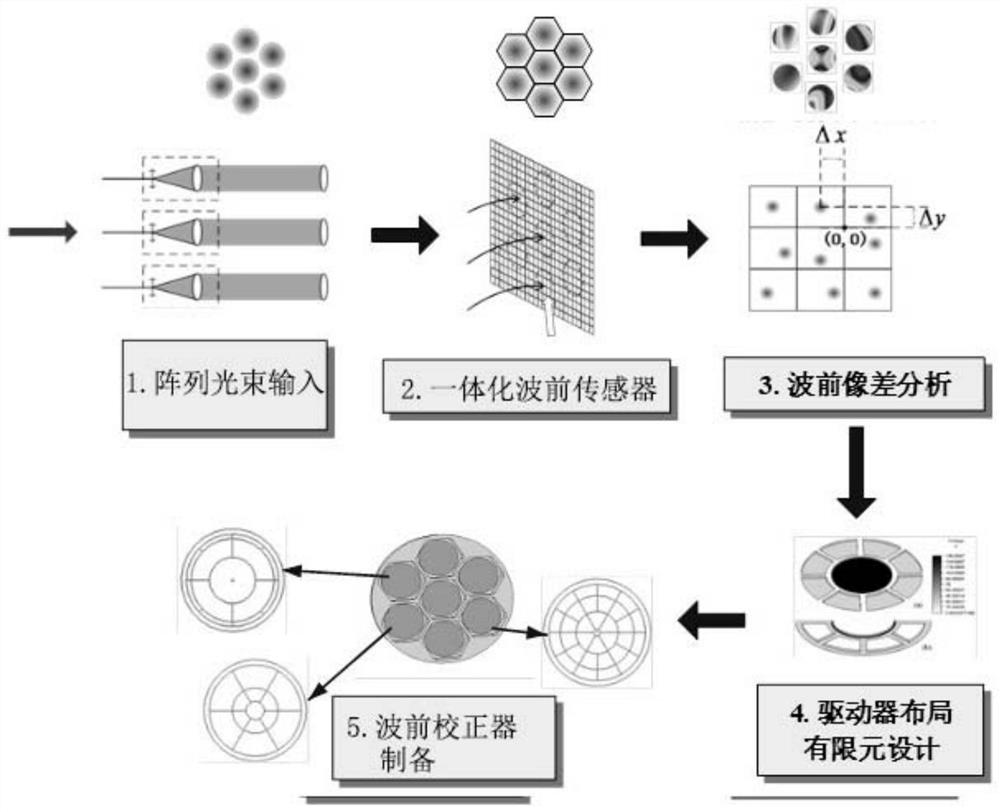

[0076] Such as image 3 As shown, the preparation method of the differential array beam wavefront corrector based on aberration measurement of the present invention, the N-way array beam is incident on the differential array beam wavefront cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com