An automatic inductance winding machine

An all-in-one machine and inductance technology, applied in coil manufacturing, electrical components assembly printed circuit, etc., can solve the problems of complex equipment structure and slow efficiency, and achieve the effect of simple setting structure, easy pick and place, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

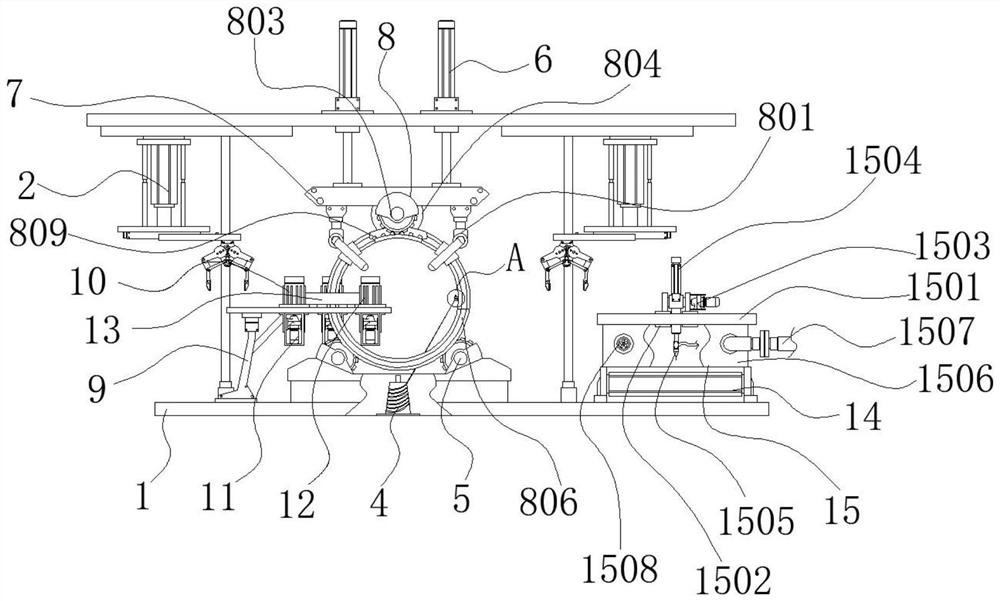

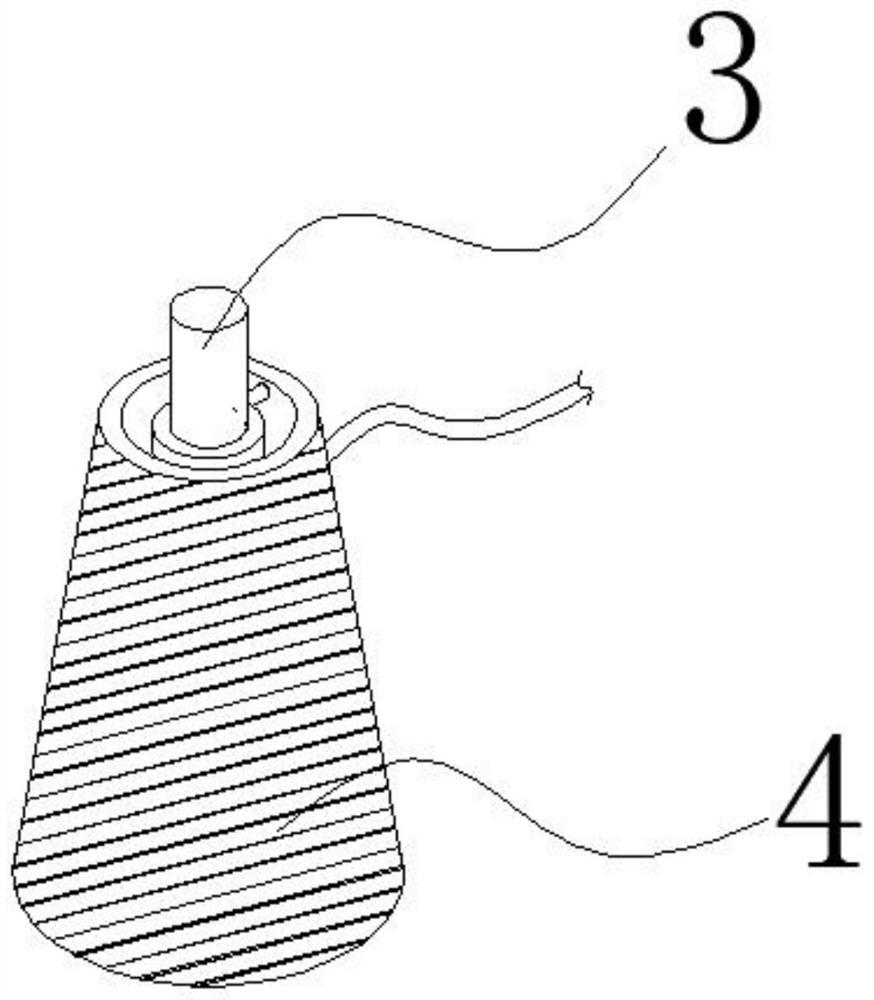

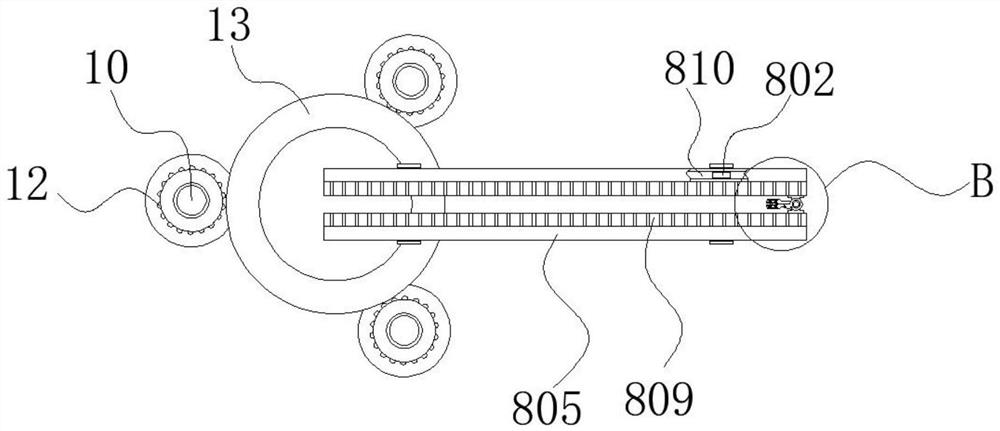

[0028] see Figure 1 to Figure 6 , the present invention provides a technical solution: an automatic inductance winding integrated machine, including a working frame 1 and a winding assembly 8, a mechanical arm 2 is arranged on both sides of the top of the working frame 1, and a torsion spring is arranged in the middle of the bottom of the working frame 1 The shaft 3 and the torsion spring shaft 3 are sleeved with a copper wire barrel 4, and the two sides of the copper wire barrel 4 are provided with auxiliary gears 5, the top of the working frame 1 is fixed with a lifting rod 6, and the bottom of the lifting rod 6 is fixed with a The lifting plate 7 and the winding assembly 8 are connected to the bottom of the lifting plate 7, the bottom left side of the operating frame 1 is fixed with a support plate 9, and the surface of the bottom of the operating frame 1 is provided with a drum 10, and the bottom of the operating frame 1 is fixed with a Rotate the motor 11, and the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com