Production process and production equipment of environment-friendly non-intumescent fire retardant coating for steel structure

A non-intumescent, fire-resistant coating technology, applied to fire-resistant coatings, mixers with rotating stirring devices, mixers, etc., can solve the problems of time-consuming and labor-intensive handling, complicated processing procedures, etc., to improve grinding efficiency, save production time, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

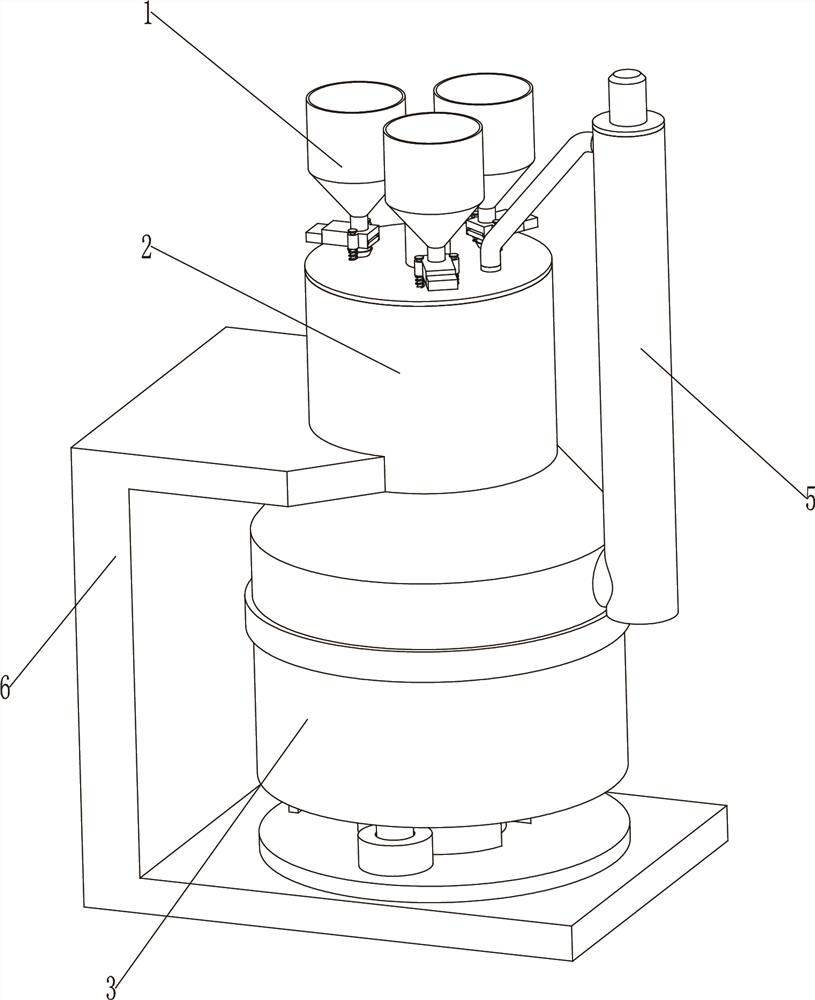

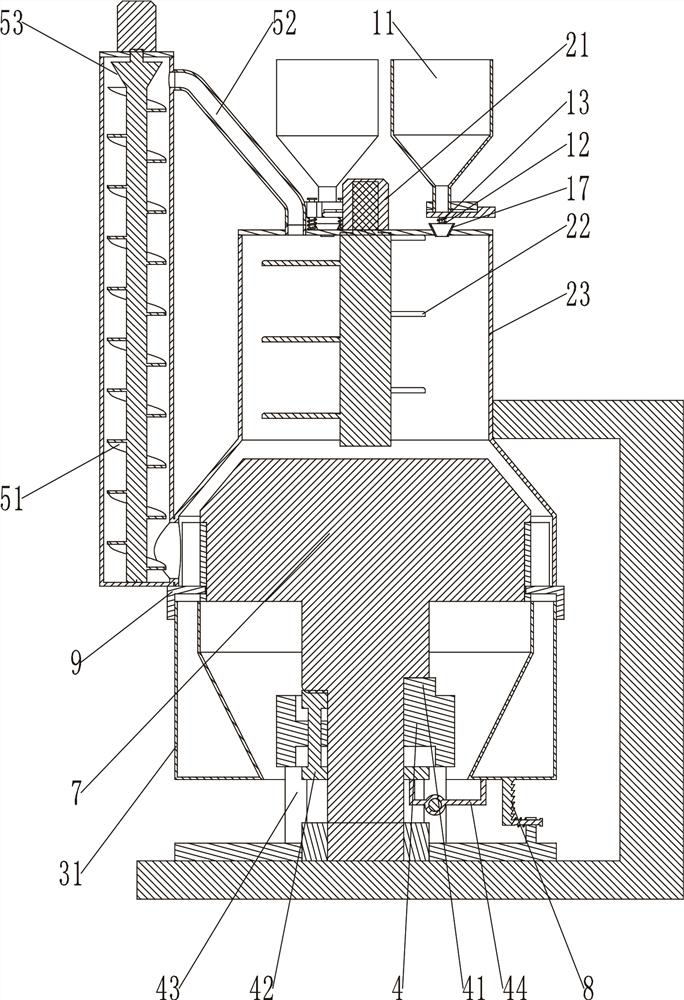

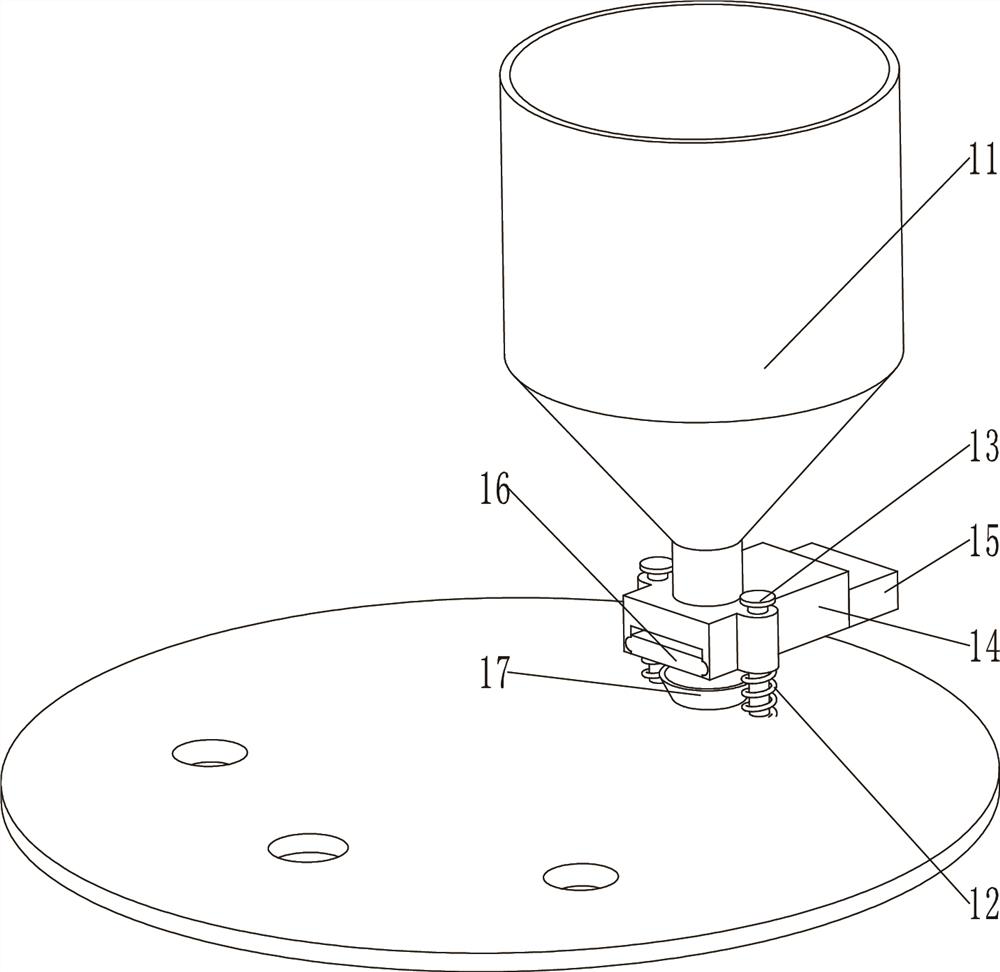

[0034] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 10 ,

[0035] A kind of production equipment of environment-friendly non-intumescent steel structure fireproof coating, comprising base 6, feeding device 1, stirring device 2, auger device 5, grinding device 7, finished product hopper assembly 3 and jacking device 4, described feeding The device 1 includes a hopper 11, a discharge port 17, a hopper guide post 13 and a feed spring 12, the hopper 11 is slidably arranged on the hopper guide post 13, and is positioned above the discharge port 17, and the feed spring 12 is slidably disposed On the hopper guide column 13, the upper end touches the bottom surface of the discharge port 17, and the lower end touches the upper plane of the stirring device 2. The bottom of the hopper 11 is provided with a sliding door 16 for controlling the switch at the bottom of the hopper. The sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com