Copper foil stamping equipment of brazing type heat exchanger for waste heat of marine main engine

A technology of ship main engine and heat exchanger, which is applied in metal processing and other directions, and can solve problems such as low production efficiency and the impact of copper foil production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

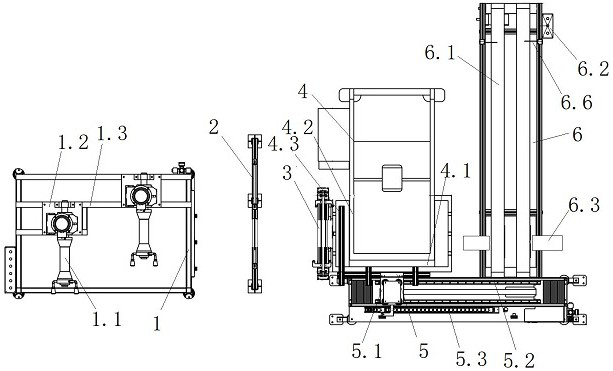

[0019] see figure 1 and figure 2 , The present invention relates to copper foil stamping equipment for brazed heat exchangers for ship main engine waste heat.

[0020] The feeder 1 is located on the left side of the press 4, and the unwinding device of the copper foil tape is placed on the left side of the feeder 1. The feeder 1 is provided with two feeding manipulators 1.1 at the front and rear, and the rear of the two feeding manipulators 1.1. The two ends are slidably matched with the bracket rail 1.3 through a mobile bracket 1.2, and the two bracket rails 1.3 are arranged side by side on the top of the feeder 1. The feeding manipulator 1.1 can move left and right along the bracket rail 1.3, so that the copper foil is absorbed by the suction cup and then moves to the right. Pull and send.

[0021] A bracket 2 and a clamping head 3 are arranged between the feeder 1 and the press 4, and the copper foil strip passes through the top of the bracket 2 and the middle of the cla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap