A system and method for automatic treatment of nicotine production waste residue

A technology for automatic processing and waste slag, which is applied in the directions of transportation and packaging, conveyor objects, loading/unloading, etc. It can solve the problems of waste slag accumulation, occupying a considerable space, and difficulty in realizing automation, so as to ensure the cutting area and promote accurate alignment , to avoid the effect of spilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

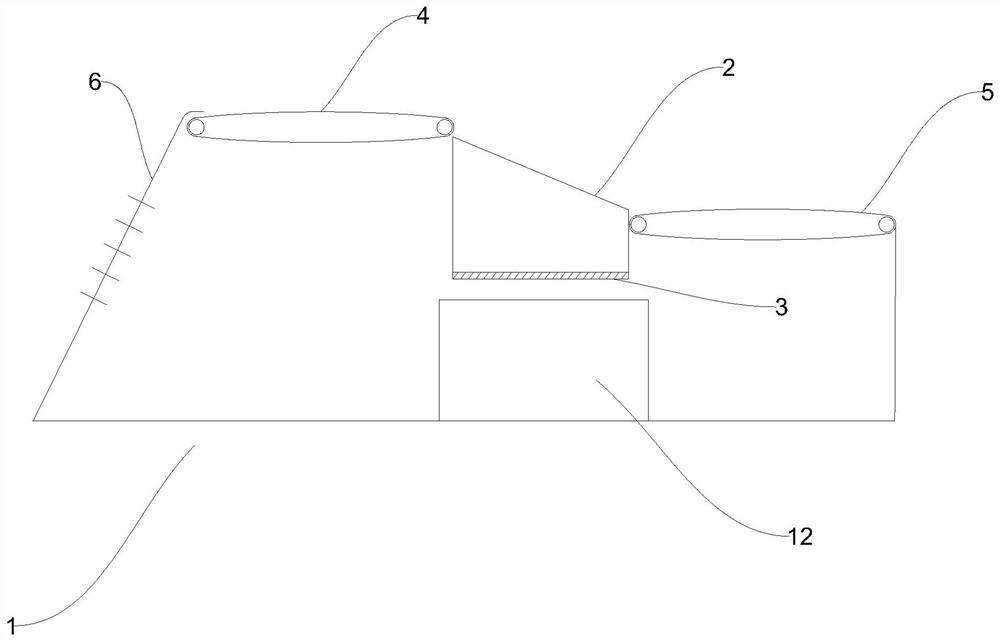

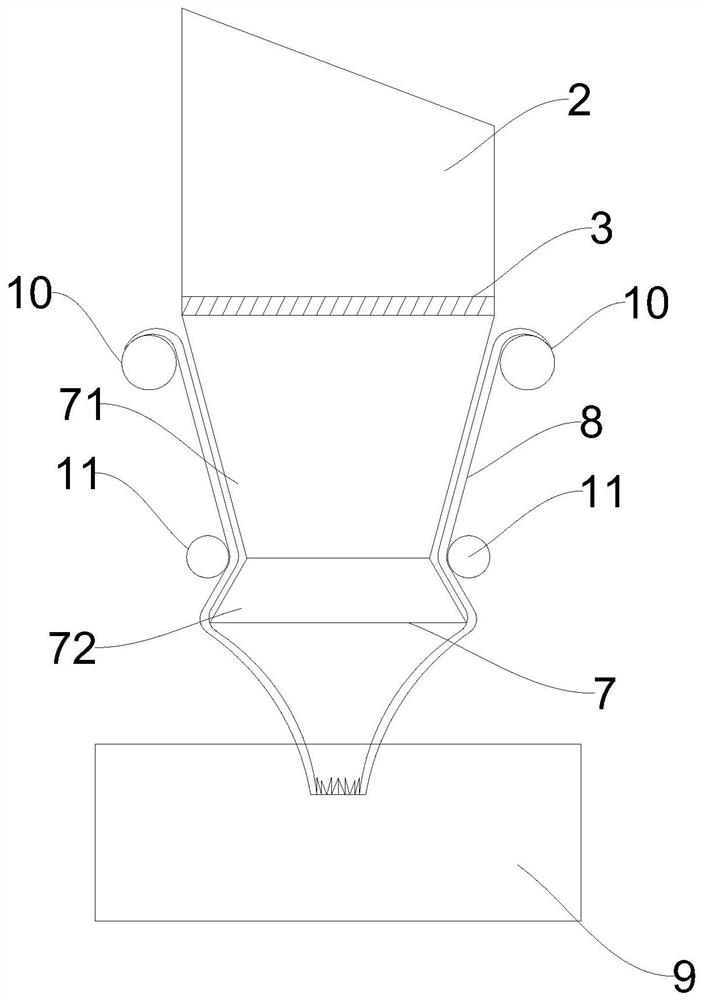

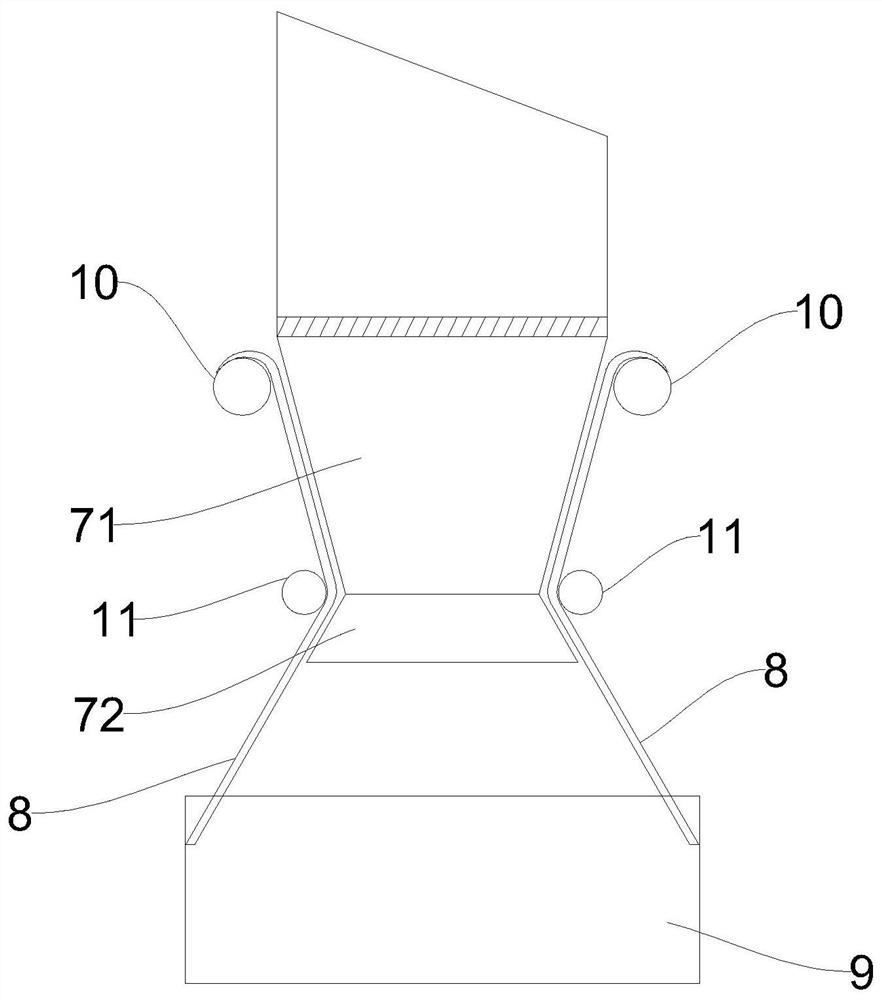

[0040] like figure 1 , 2 As shown, this embodiment discloses an automatic treatment system for nicotine production waste slag, including a return transmission device 1, a storage tank 2, and a collection vehicle (not shown in the figure), and the return transmission device 1 receives the upper waste slag And sent to the storage tank 2 and / or left on the return transfer device 1 to continue driving, such as figure 1 , 4 As shown, the bottom of the storage tank 2 is provided with an opening and closing door 3 matching the opening, and the opening and closing door 3 releases the waste residue in the storage tank 2 after the collection vehicle is positioned under the opening and closing door. The door 3 adopts a controlled hydraulic opening and closing door, and the collecting vehicle includes a vehicle body and a receiving hopper 9 arranged on the vehicle body.

[0041] The return conveying device includes a high-position conveying device 4, a low-position conveying device 5, ...

Embodiment 2

[0053] This embodiment discloses an automatic treatment method for nicotine production waste residue, which is carried out by using the above-mentioned automatic treatment system, including steps:

[0054] A1, the return transmission device 1 receives the waste residue and transmits it;

[0055] A2. When the transmission passes through the storage tank 2, if the storage tank 2 is not filled completely, fill the waste residue into the storage tank 2; if the storage tank 2 is completely filled, continue to drive the remaining unfilled waste residue and receive new ones. Waste slag is generated and filled in after passing through the incompletely filled storage tank 2;

[0056] A3. The collection vehicle receives the signal that the storage tank 2 is fully filled and moves to the bottom of the storage tank 2 to collect the released waste residue.

Embodiment 3

[0058] This embodiment discloses a building on which the above-mentioned automatic processing system is set. That is to say, the above-mentioned automatic processing system is arranged in the building, and the arrangement of the components of the automatic processing system is more convenient through the multi-layer structure of the building. And it is easy to be independent and automated.

[0059] Specifically, it includes a ground floor building and a multi-storey device installation building arranged above the base building, where a collection vehicle parking room 12 is arranged in the bottom building, and a horizontally extending conveying device installation space is provided in the multi-storey device installation building , and there is also a longitudinally extending transmission device installation space between the adjacent device installation buildings, and a transition layer building is also provided between the ground floor building and the adjacent device install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com