Thin-film lithium niobate electro-optical modulator and preparation method thereof

An electro-optical modulator, lithium niobate technology, applied in the field of optical communication, to achieve the effect of improving feasibility, increasing spacing, and increasing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

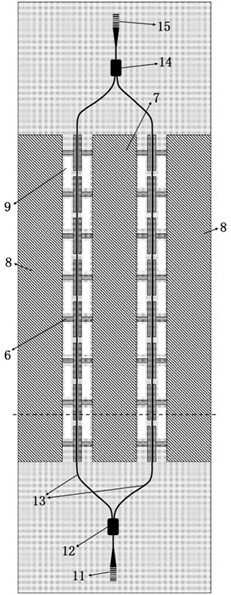

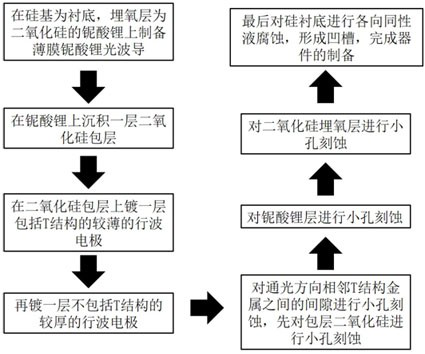

[0055] Such as figure 1 and Figure 10 As shown, a thin-film lithium niobate electro-optic modulator includes a substrate 1, a buried oxide layer 2, and a lithium niobate layer 3 sequentially arranged from bottom to top, and the upper surface of the lithium niobate layer is etched to form a thin-film lithium niobate optical modulator. The waveguide 4 and the cladding layer 5 are arranged on the upper surface of the lithium niobate layer and cover the thin-film lithium niobate optical waveguide; the thin-film lithium niobate optical waveguide includes an input grating 11, a 1*2 beam splitter 12, and a Mach-Zehnder structure 13, 2* 1 beam combiner 14 and output grating 15; the input grating is connected to the input end of the 1*2 beam splitter, and the output end of the 1*2 beam splitter is connected to the input end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com