Material balance calculation method based on oil-contaminated soil cleaning treatment process and application of material balance calculation method

A soil and material technology, applied in special data processing applications, electrical digital data processing, instruments, etc., can solve the problems of inability to obtain precise control of the cleaning process, unstable effects, and failure to achieve precise control of the pollutant migration characteristics of the cleaning system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

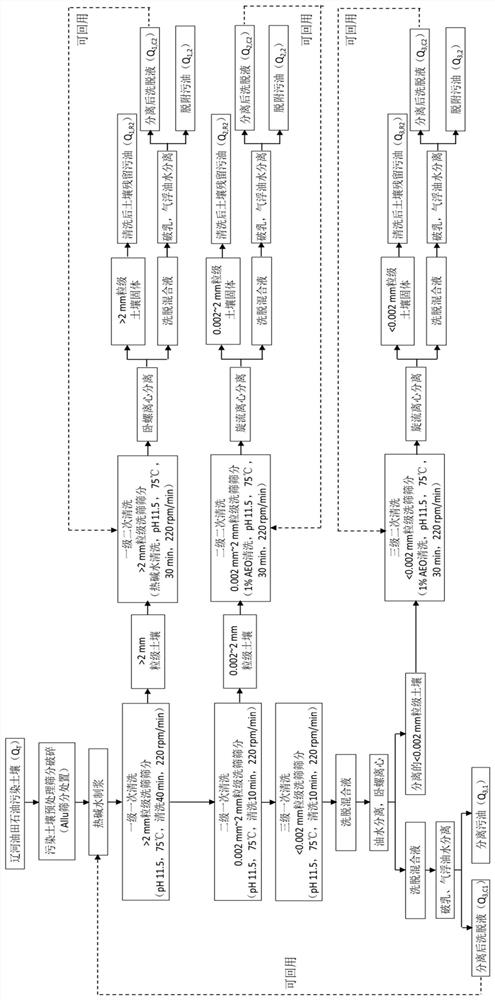

[0065] Example 1 Establishment of Material Balance Accounting Relationship of Ex-situ Cleaning and Disposal of Oil Contaminated Soil

[0066] The high-concentration petroleum-contaminated soil landed in the oilfield area where the Liaohe Oilfield is located is used as the disposal object, and the high-concentration petroleum-contaminated soil is cleaned and disposed of with fatty alcohol polyoxyethylene ether (AEO) and other cleaning agents. During the cleaning process, quantitative analysis was carried out on the total amount of dirty oil and its group composition in each material (including soil with different particle sizes, eluent water and desorbed dirty oil) at each disposal node, so as to establish the cleaning process Material balance relationship of dirty oil. The oil content of the treated oily soil was 4.25% (w / w, g / g), of which saturated hydrocarbons accounted for 63.2%, aromatic hydrocarbons accounted for 16.7%, colloids accounted for 13.2%, and asphaltenes accoun...

Embodiment 2

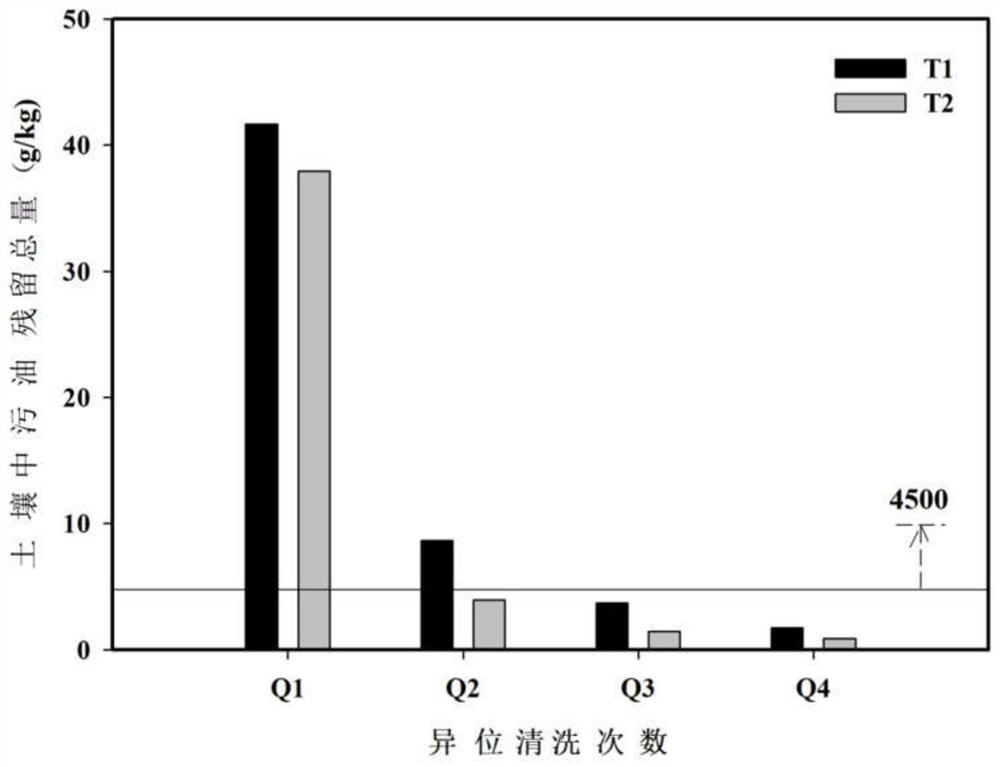

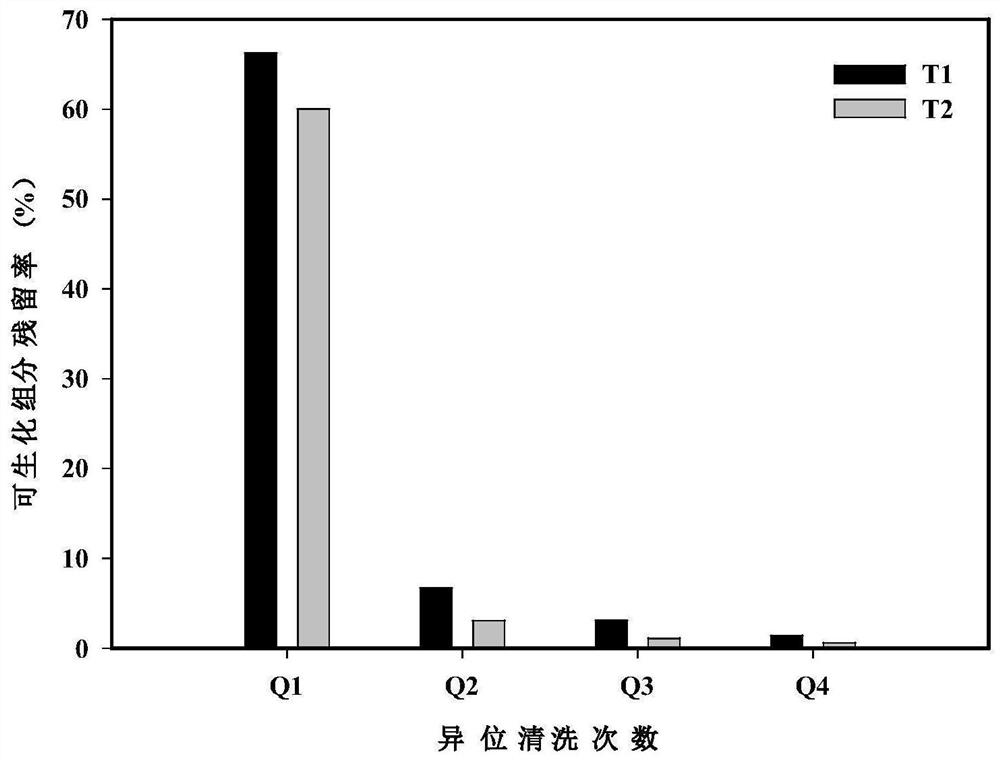

[0105] Example 2 Optimizing Process Parameters for Ex-situ Cleaning and Disposal of Oil Contaminated Soil Using Waste Oil Material Balance

[0106] The oil-contaminated soil around the oil well of the Gudao Oil Production Plant of Shengli Oilfield was used as the disposal object for ex-situ cleaning. Since the optimal ex-situ cleaning parameters have not yet been obtained, a three-level and four-time cleaning process was set according to the cleaning and disposal engineering experience, specifically including Under the conditions of 70°C, pH 11.5, solid-to-liquid ratio 5:1, cleaning cycle 30min (Test 1) and 80°C, pH 13, solid-liquid ratio 3:1, cleaning cycle 40min (Test 2) Cleaning; the cleaning process includes first cleaning with hot alkaline water under the above conditions, washing and sieving the soil particles during the cleaning process, and sieving out the soil particle components with a particle size of >3mm, 0.02-3mm and <0.02mm respectively; Then, the soils with dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com