Solid electrolyte LLZO powder and preparation method thereof

A solid electrolyte, solid electrolyte technology, applied in electrolytes, circuits, electrical components and other directions, can solve the problems of easy generation of lithium carbonate layer, high cost, complex process, etc., and achieve simple and easy methods, reduced production costs, and stable surfaces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Another aspect of the present invention provides a method for preparing the above-mentioned solid electrolyte LLZO powder, comprising the following steps:

[0034] Step 1, preparing inner core powder; In some embodiments, the titanium source can be nano titanium dioxide; the aluminum source can be nano aluminum oxide; the phosphorus source can be ammonium dihydrogen phosphate, ammonium phosphate one or several;

[0035] Specifically, the method for preparing inner core powder comprises the following steps:

[0036] Step a, weigh the lithium source, lanthanum source, and zirconium source according to the stoichiometric ratio, and put them into a mixer to mix uniformly to obtain mixture 2; in some embodiments, the lithium source can be lithium hydroxide, and the lanthanum The source can be nano-lanthanum trioxide; the zirconium source can be nano-zirconium dioxide;

[0037] Step b, put the mixture 2 into a sagger, and place it in a sealed roller kiln at 900-1000°C for 1...

Embodiment 1

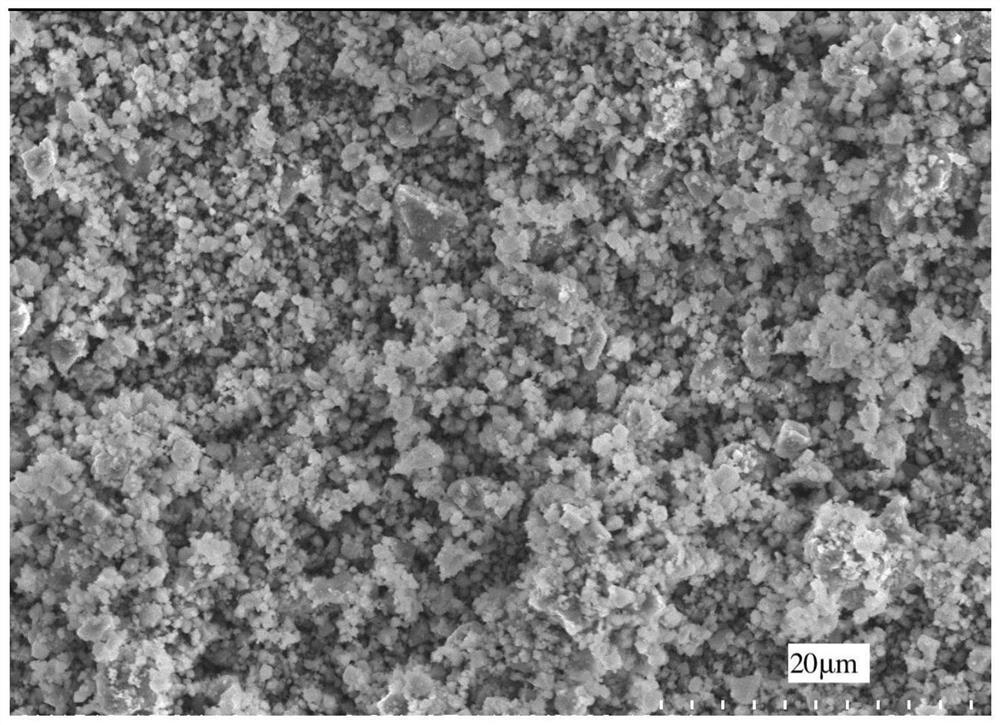

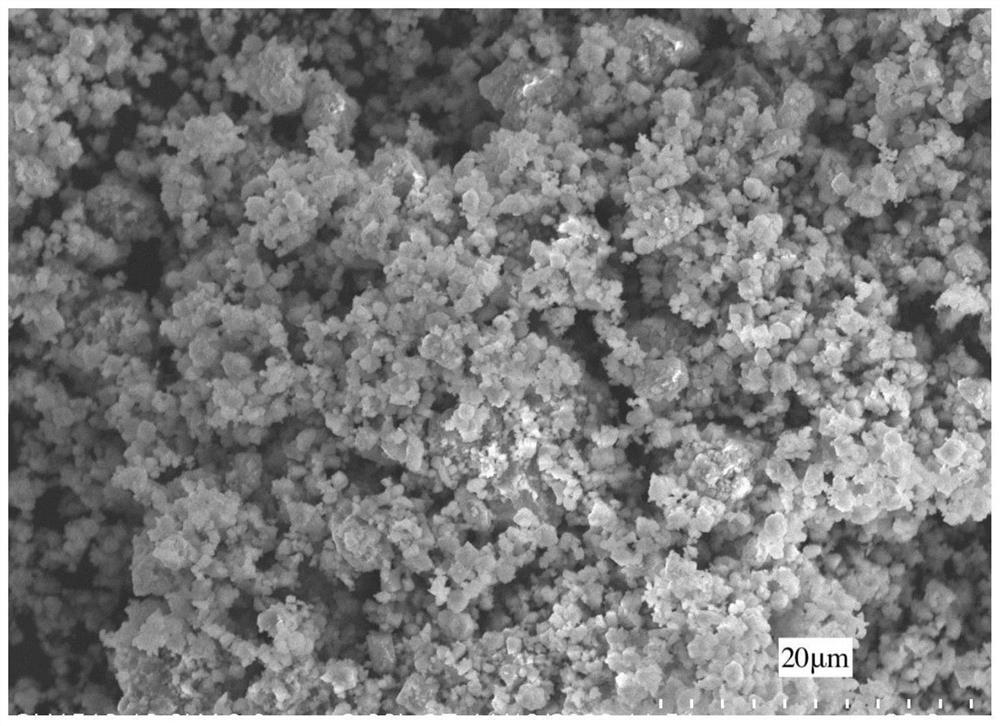

[0043] Weigh 175kg of lithium hydroxide, 291kg of nanometer lanthanum trioxide and 147kg of nanometer zirconium dioxide, put them into a high-speed mixer and mix them evenly to obtain a mixture. Put the mixture into a sagger, enter the sealed roller kiln for sintering, the sintering temperature is 1000℃, and the sintering time is 16h. During the sintering process, an appropriate amount of air to remove carbon dioxide is introduced to keep the kiln at a slightly positive pressure. The sintered material was crushed, crushed, classified and sieved to obtain 490 kg of uncoated LLZO powder. Detect the surface lithium carbonate content of the powder to be: 1000ppm. Put 490kg of the above-mentioned LLZO powder, 3.51kg of ammonium dihydrogen phosphate, 0.16kg of nano-aluminum oxide, and 1.38kg of nano-titanium dioxide into a high-speed mixer and mix evenly, then put it into a sagger, and enter a sealed roller kiln for sintering. The temperature is 900℃, and the sintering time is 6h....

Embodiment 2

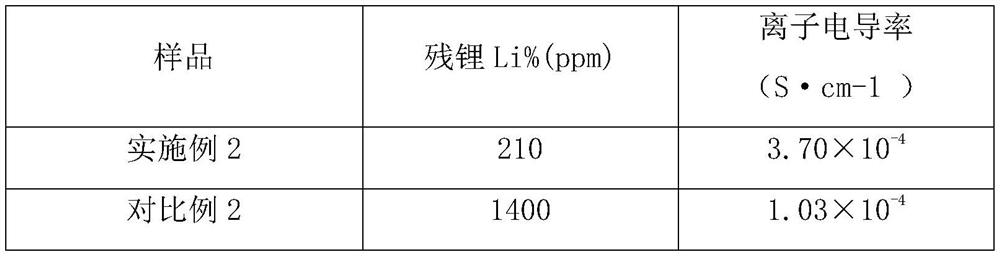

[0045]Weigh 175kg of lithium hydroxide, 291kg of nanometer lanthanum trioxide and 147kg of nanometer zirconium dioxide, put them into a high-speed mixer and mix them evenly to obtain a mixture. Put the mixture into a sagger, enter the sealed roller kiln for sintering, the sintering temperature is 900°C, and the sintering time is 16h. During the sintering process, an appropriate amount of nitrogen gas is introduced to keep the kiln at a slightly positive pressure. The sintered material was crushed, crushed, classified and sieved to obtain 492 kg of uncoated LLZO powder. The surface lithium carbonate content of the powder detected is: 1300ppm. Put 490kg of the above-mentioned LLZO powder, 4.59kg of ammonium dihydrogen phosphate, 0.2kg of nano-alumina, and 1.81kg of nano-titanium dioxide into a high-speed mixer and mix evenly, then put it into a sagger, and enter a sealed roller kiln for sintering. It is 1000℃, and the sintering time is 6h. During the sintering process, an app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com