Office keyboard key surface screen printing equipment

A technology of surface silk and keys, applied in screen printing, screen printing machine, printing and other directions, can solve the problems of affecting keyboard usage, poor stability, reduced work efficiency, etc., to avoid losses, reduce work intensity, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

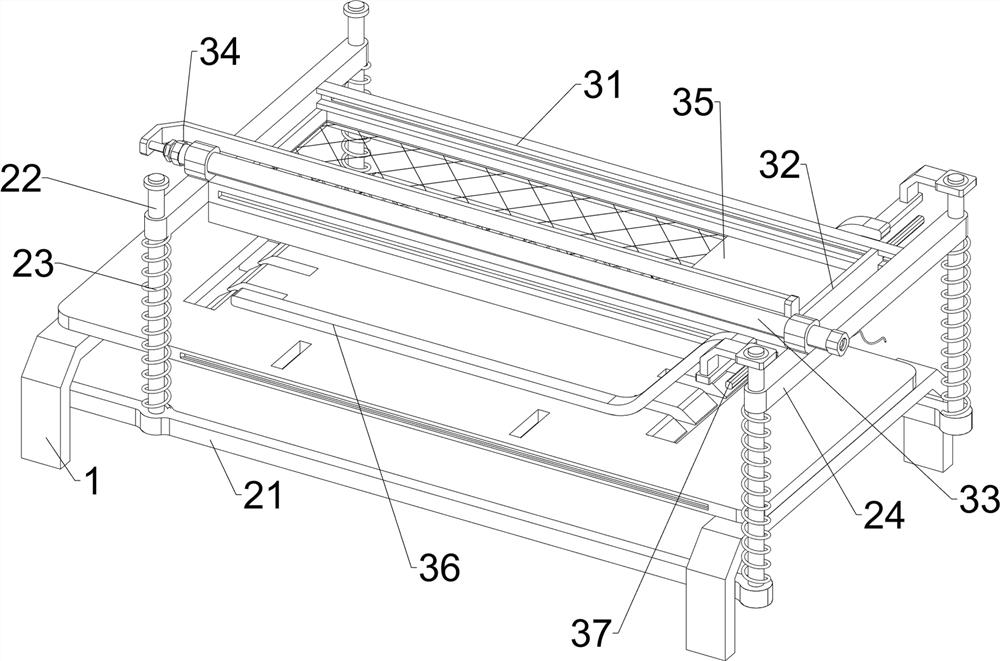

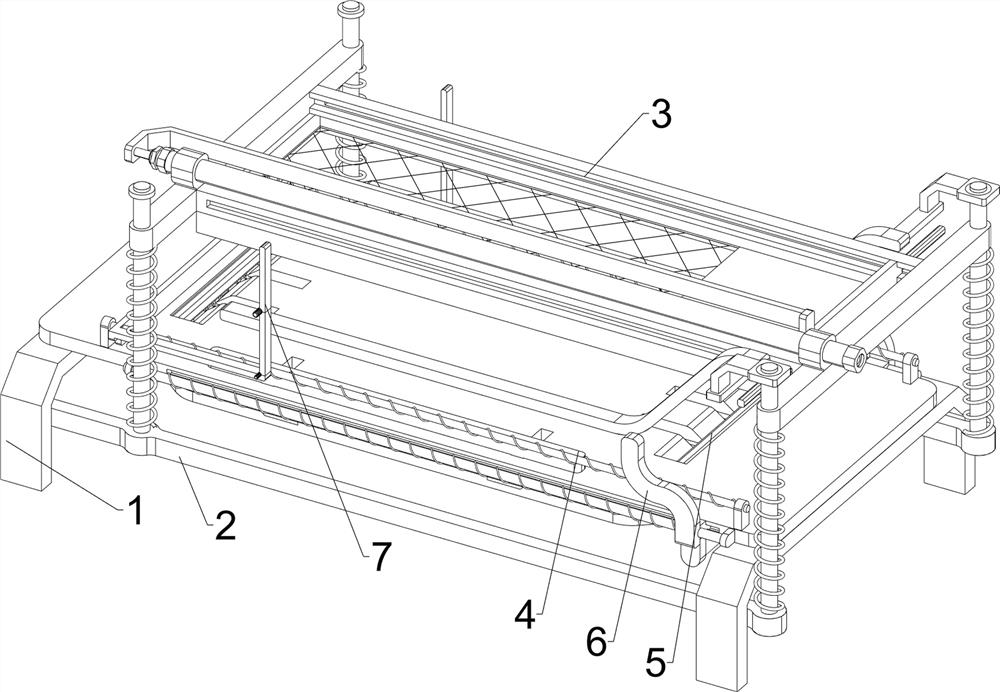

[0026] One office keyboard button surface silk screen equipment, such as figure 1 with figure 2 As shown, there is a base 1, a lifting mechanism 2, and a printing mechanism 3, and a lifting mechanism 2 is provided in the bottom of the base 1, and a printing mechanism 3 is provided at the top of the lifting mechanism 2.

[0027] When people need to print the surface of the keyboard button, people manually place the keyboard on the base 1, and drive the printing mechanism 3 to align the keyboard button under the action of the lifting mechanism 2, and then launch the printing mechanism 3, in the printing mechanism 3 Under the action, the surface of the keyboard button is printed, and after the keyboard button is pressed, the printing mechanism 3 is turned off.

[0028] The lifting mechanism 2 includes a first mounting frame 21, a first guide rod 22, a first spring 23, and a slide frame 24, and the inner side of the base 1 is sided there is a first mounting frame 21, and the first mou...

Embodiment 2

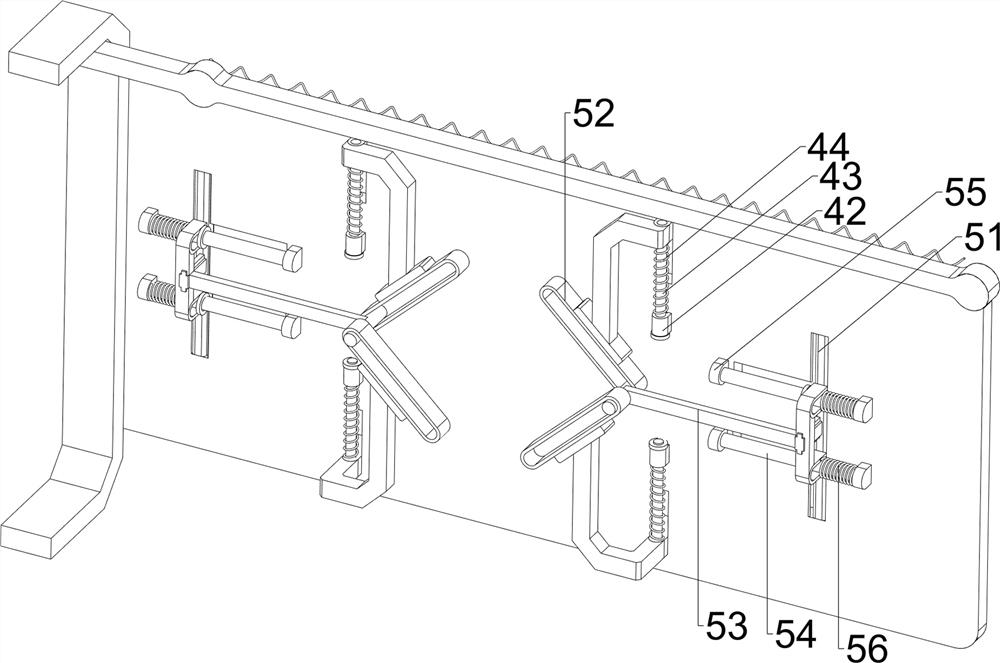

[0032] On the basis of Example 1, such as image 3 , Figure 4 , Figure 5 with Image 6As shown, there is a clamping mechanism 4, the clamping mechanism 4 includes a jam 41, a second mounting frame 42, a second guide rod 43, and a second spring 44, and the bottom of the base 1 are symmetrical. The frame 42, the second mounting frame 42 is provided with a second guide rod 43, and the second guide rod 43 is slidably provided with a clamping bar 41, and the strip 41 is slidable, and the second mounting frame 42 and the clip are slid. A second spring 44 is provided between the rods 41, and the second spring 44 is all sleeved on the second guide rod 43.

[0033] When people put the printed keyboard on the base 1, people manually move the jocket 41 inward, so that the jaw 41 is clamped to the keyboard, at this time, the second spring 44 is compressed, and the keyboard is made under the action of the jaw 41. The printing work can be performed stable. When the surface printing of the keyboar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com