Winding device for sodium bentonite waterproof blanket

A technology of sodium-based bentonite and winding device, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of inconvenient handling, heavy weight of waterproof blanket, stretching damage of waterproof blanket surface, etc., to achieve Ease of use, simple structure, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

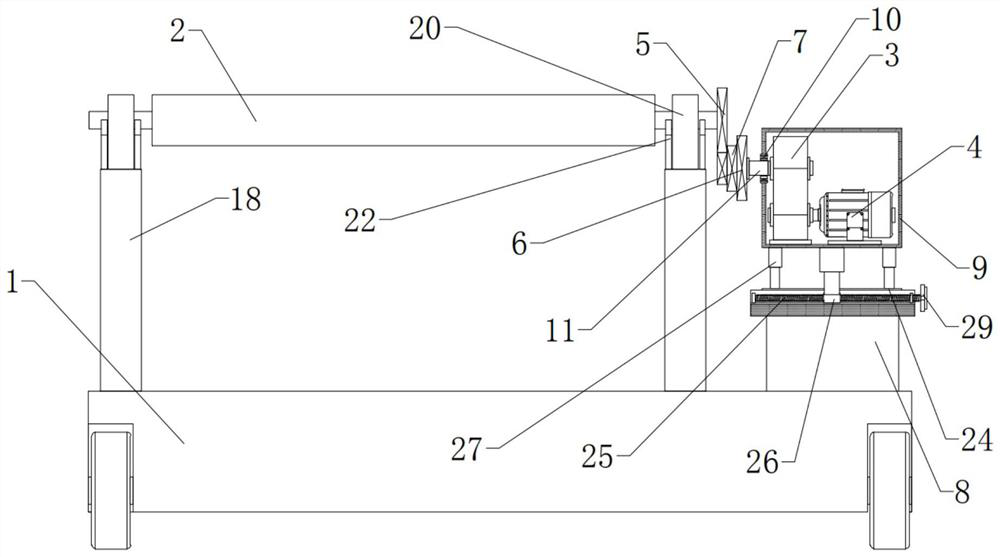

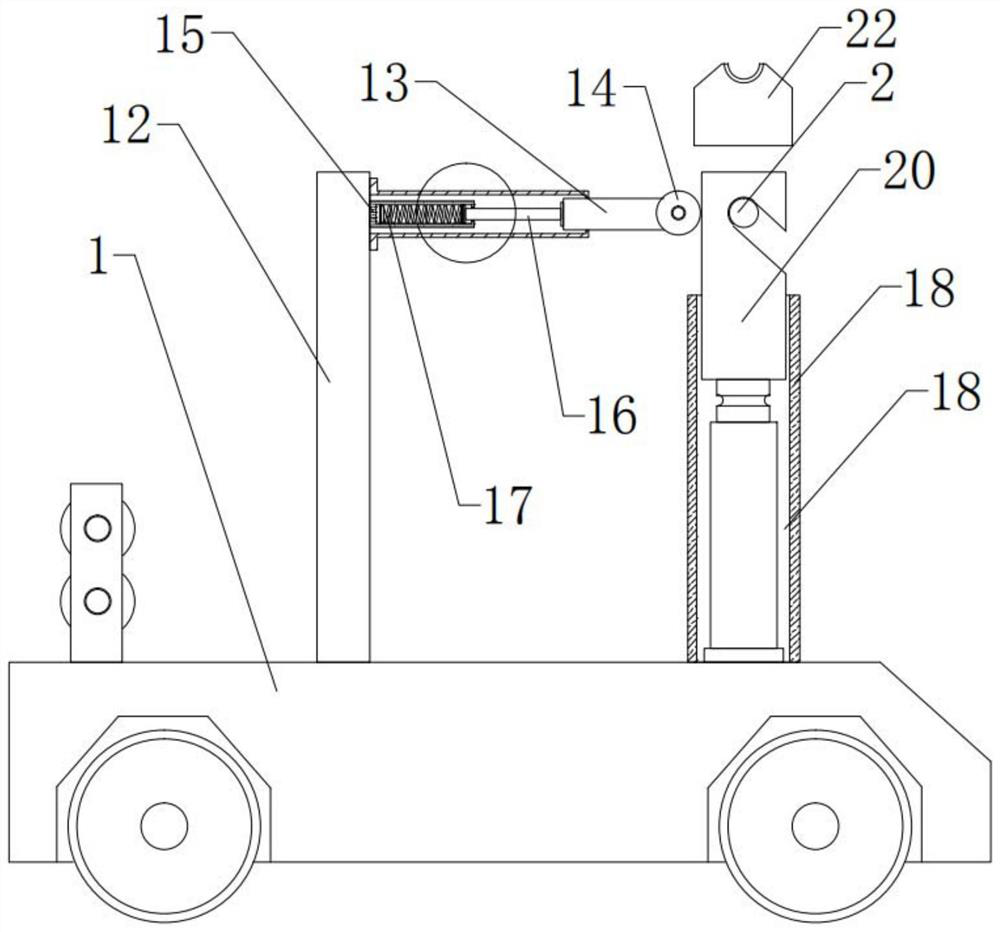

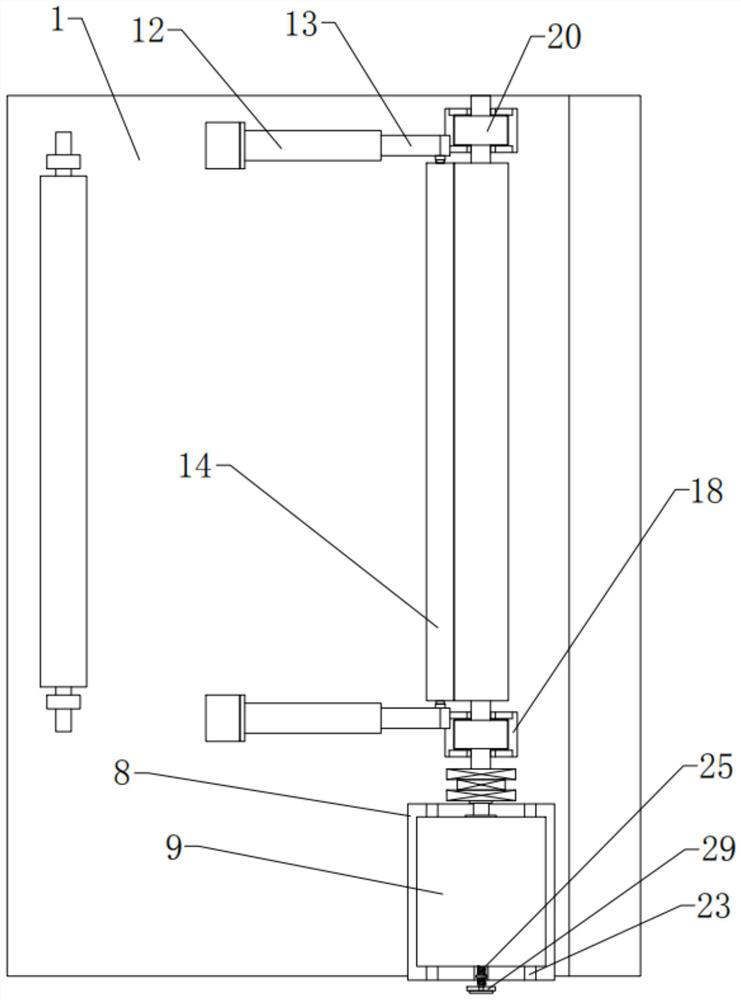

[0032] Embodiment: according to specification Figure 1-5 It can be seen that this case is a winding device for a sodium-based bentonite waterproof blanket, including a support frame 1, a winding roller 2, a speed reducer 3 and a driving machine 4. The support frame 1 is provided with a winding roller 2, and the speed reducer 3 is installed on the One side of the support frame 1 is connected with the driving end of the driver 4, the end of the winding roller 2 is provided with a traction force adjustment mechanism and connected with the output end of the reducer 3, and on the support frame 1 and located at the side of the winding roller 2 Rewinding and compacting structure, the support frame 1 is connected with the winding roller 2 with a disassembly mechanism, in the specific implementation process, the support frame 1 is the overall support of the preparation, the driving machine 4 is connected with the reducer 3 to provide power for the equipment, through The traction force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com