Lithium carbonate solar pond and lithium carbonate extraction method

An extraction method, lithium carbonate technology, applied in the direction of lithium carbonate; Ease of operation and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

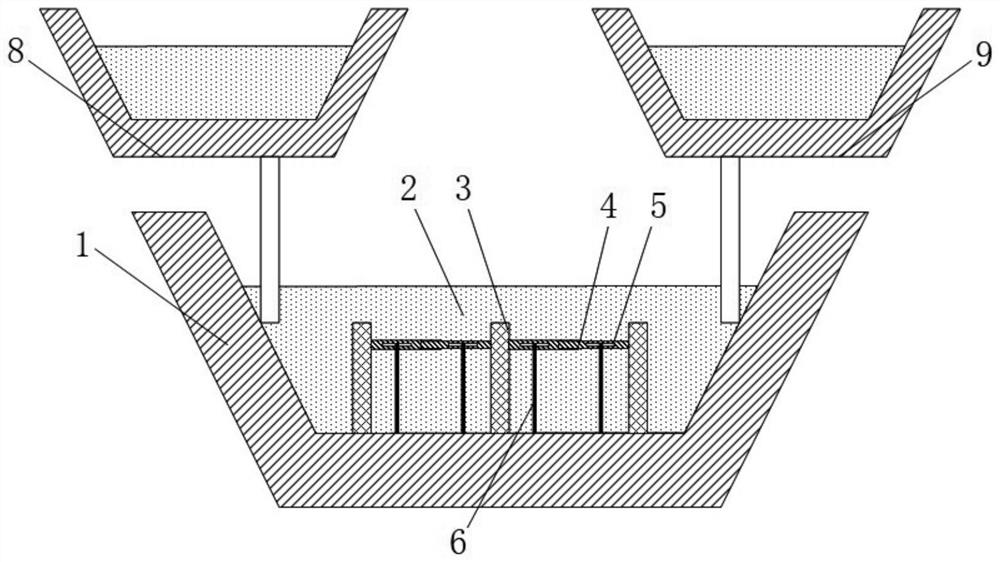

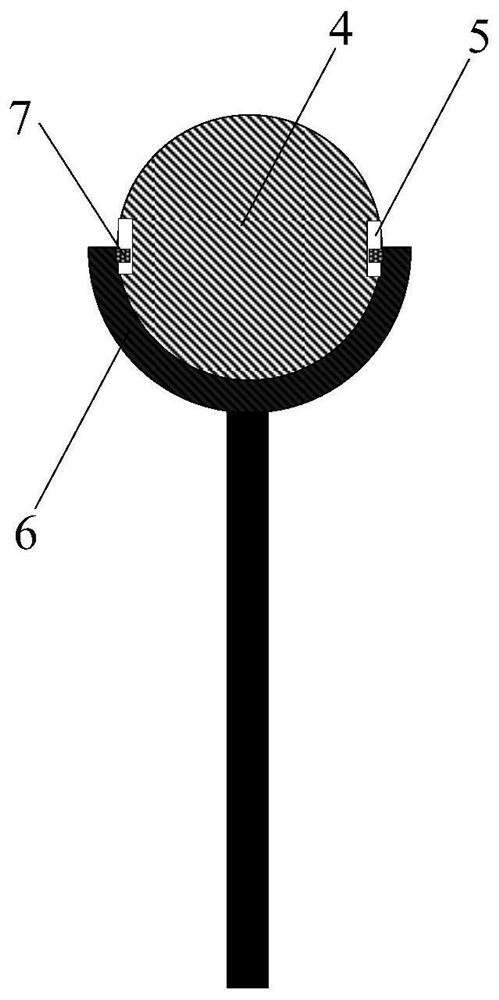

[0054] A specific embodiment of the present invention discloses a lithium carbonate solar pool, mainly for extraction of lithium carbonate in the field, and the solar pool is built in the field salt lake area, see Figure 1 to Figure 2 , Lithium carbonate solar pool includes:

[0055] Tail brine pool 8, tail brine pool 8 is configured to accommodate the first Li + Concentration, the first CO 3 2- Concentration of tail brine;

[0056] A halogen pool 9, which is configured to accommodate the second Li + concentration, the second CO 3 2- Concentration of halides;

[0057] Analyze lithium pool 1, analyze lithium pool 1 and tail brine pool 8 and form halogen pool 9 and connect, to accommodate the first Li + The concentration of the tail halogen and the second Li + Mixed brine with a concentration of brine, and as a place for the precipitation of lithium carbonate mixed salt;

[0058] Among them, the first Li + concentration greater than the second Li + concentration, the...

Embodiment 2

[0083] Another specific embodiment of the present invention discloses a method for extracting lithium carbonate, the operation process is as follows Figure 4 Shown, lithium carbonate extraction method comprises the steps:

[0084] Step 1: The tail brine in the tail brine pool 8 and the brine formed in the brine forming pool 9 are mixed for brine, and the brine is poured into the lithium analysis pool 1 to obtain brine, wherein the Li in the tail brine + Concentration greater than Li in halide + Concentration, CO in Tail Brine 3 2- Concentration is less than CO in halide 3 2- concentration;

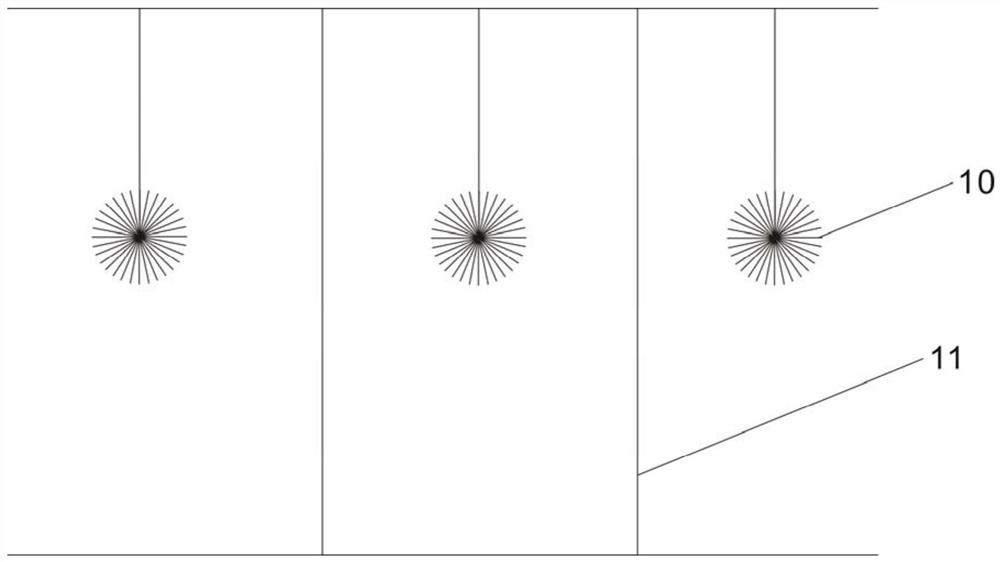

[0085] Step 2: Lay a freshwater layer on the surface of the brine, let it stand for several days, and make a salt gradient solar pond;

[0086] Step 3: When the salt gradient solar pool enters the stage of stable temperature rise and lithium analysis, monitor the Li in the brine of the lithium analysis layer (lower troposphere) at the bottom of the lithium analysis pool + Concentra...

example 1

[0097] High Li + low CO 3 2- The brine was taken from the tail brine in winter after lithium analysis in the G4 solar pool of a workshop in the Zabuye mining area of Tibet. The sampling depth was 160cm. Li in the brine + The concentration is 1.93g / L, CO 3 2- The concentration is 25.44g / L, the brine temperature is 24.8°C, and the brine density is 1.233g / cm 3 . Low Li + High CO 3 2- The brine is taken from the 2# salt field of a workshop in Zabuye Mining Area, Tibet, where the brine is brine in summer, and the Li in the brine + The concentration is 1.69g / L, CO 3 2-The concentration is 53.52g / L, and the brine temperature is 12.0°C. The two are mixed according to the ratio of 1:1.25, 1:1.5 and 1:2, and the total volume of the brine is controlled to be 3000mL. After fully stirring, seal and place in a water bath for heating in a water bath at 40°C for a total of 42 hours. Use a suction filter to separate the solution from solid to liquid, dry and weigh the solid phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com