High-transparency low-shrinkage TPU film and preparation method thereof

A low shrinkage, film technology, applied in the field of high transparency and low shrinkage TPU film and its preparation, to achieve the effect of high mechanical strength and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

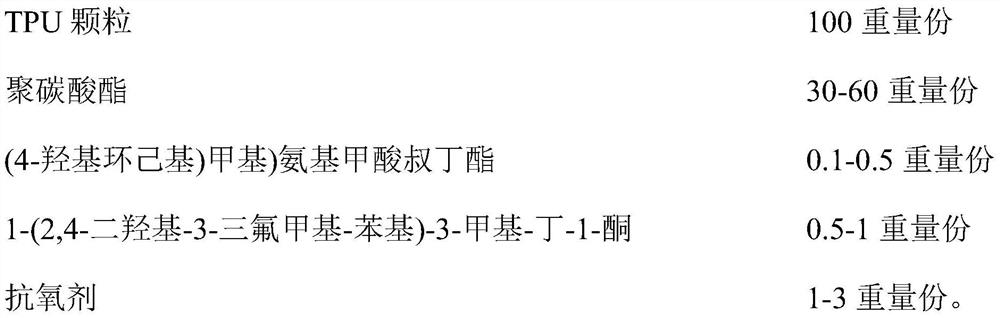

[0033] In the present embodiment, a TPU film having a high transparent low shrinkage is provided, and the prepared material of the TPU film of the high transparent low shrinkage ratio includes a weight part of the component:

[0034]

[0035] The TPU particles are polyester TPU particles (German Bayer 5377), and the weight average molecular weight of polycarbonate is 40,000 (Liaocheng Tongda Chemical), and the antioxidant is an antioxidant 3114.

[0036] Its preparation method includes the following steps:

[0037] (1) TPU particles were mixed with (4-hydroxycyclohexyl) methyl) carbamate and an antioxidant mixed under the rotational speed 700R / min, and the double screw extruder was added from the main feed opening;

[0038](2) Polycarbonate with 1- (2,4-dihydroxy-3-trifluoromethyl-phenyl) -3-methyl-buthalone is mixed under the rotational speed 200R / min, from the side The feed opening is added to the twin screw extruder, extruded molding, and the twinkling speed of the twin-s...

Embodiment 2

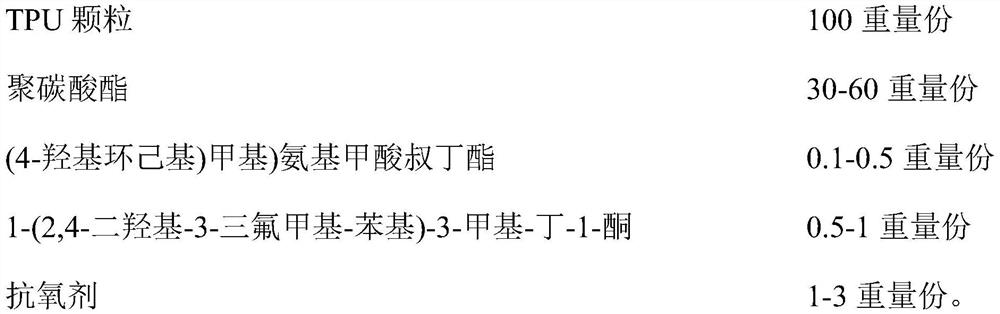

[0040] In the present embodiment, a TPU film having a high transparent low shrinkage is provided, and the prepared material of the TPU film of the high transparent low shrinkage ratio includes a weight part of the component:

[0041]

[0042] The TPU particles are polyester TPU granules (German Bayer 5377), and the weight average molecular weight of polycarbonate is 40,000 (Liaocheng Tongda Chemical), and the antioxidant is an antioxidant 1010.

[0043] Its preparation method includes the following steps:

[0044] (1) TPU particles were mixed with (4-hydroxy cyclohexyl) methyl) carbamate and an antioxidant for 30 min under the rotational speed of 600r / min, and the double screw extruder was added from the main feed opening;

[0045] (2) Polycarbonate and 1- (2,4-dihydroxy-3-trifluoromethyl-phenyl) -3-methyl-1-ketone mixed under the rotational speed 300R / min, from the side The feed opening is added to the twin screw extruder, extruded molding, and the twinkling speed of the tw...

Embodiment 3

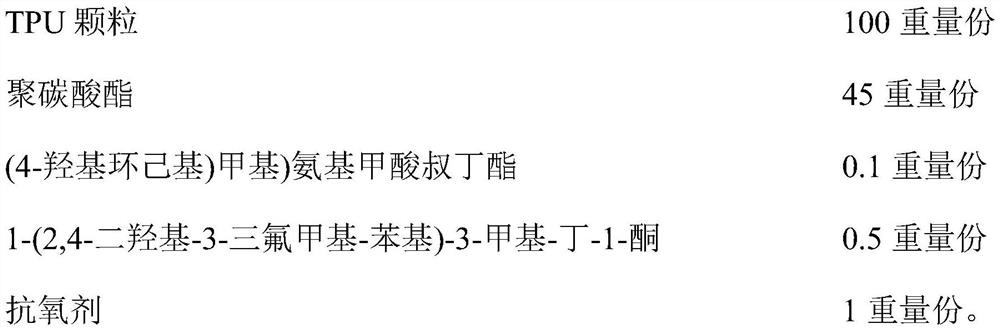

[0047] In the present embodiment, a TPU film having a high transparent low shrinkage is provided, and the prepared material of the TPU film of the high transparent low shrinkage ratio includes a weight part of the component:

[0048]

[0049] The TPU granules are polyester TPU particles (German Bayer 5377), the weight average molecular weight of polycarbonate is 40,000 (Liaocheng Tongda Chemical), and the antioxidant is an antioxidant 168.

[0050] Its preparation method includes the following steps:

[0051] (1) TPU particles were mixed with (4-hydroxycyclohexyl) methyl) carbamate and antioxidants for 15 min under the rotational speed 1000r / min, and the double screw extruder was added from the main feed opening;

[0052] (2) Polycarbonate with 1- (2,4-dihydroxy-3-trifluoromethyl-phenyl) -3-methyl-but 1-ketone is mixed under the rotational speed 100R / min, from the side The feed opening is added to the twin screw extruder, extruded molding, and the twinkling speed of the twin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com