Preparation method of novel inorganic hybrid modified acrylic coating

A technology of acrylic and acrylic resin, which is applied in the direction of chemical instruments and methods, coatings, mixers, etc., can solve the problems of poor weather resistance and chemical resistance, and achieve improved weather resistance and salt spray resistance, improved fusion, and shortened The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

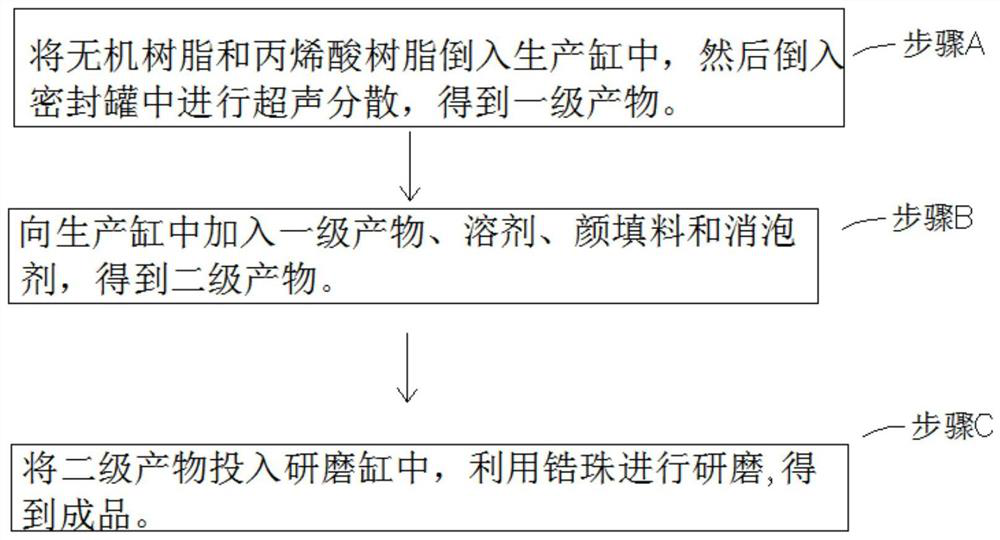

[0045] like figure 1 Shown, a novel method for preparing a modified inorganic hybrid of acrylic coatings, comprising the steps of:

[0046] Step A: 15 parts by weight of an inorganic resin and 40 parts by weight of an acrylic resin is poured into the production of the cylinder, the rotational speed is set to 1800r / min, the stirring time to 10min, then poured into a sealed can was subjected to ultrasonic dispersion time is set to 15min , to give a product;

[0047] Step B: To the product of the production of a cylinder, 1 part by weight of solvent, 20 parts by weight of pigment and 0.5 parts by weight of an antifoaming agent, set the speed of 1800r / min, stirring time 10min, to give two products;

[0048] Step C: The product of two cylinders into a grinding, polishing using zirconium beads, grinding twice, each time the polishing 15min, to obtain the finished product.

[0049] Said step A comprises: T1: 15 parts by weight of an inorganic resin and 40 parts by weight of acrylic r...

Embodiment 2

[0051] like figure 1 Shown, a novel method for preparing a modified inorganic hybrid of acrylic coatings, comprising the steps of:

[0052] Step A: 20 parts by weight of an inorganic resin and 60 parts by weight of an acrylic resin is poured into the production of the cylinder, the rotational speed is set to 2200r / min, the stirring time to 15min, then poured into a sealed can was subjected to ultrasonic dispersion time is set to 20min , to give a product;

[0053] Step B: To the product of the production of a cylinder, 10 parts by weight of the solvent, 30 parts by weight of pigment and 1 part by weight of an antifoaming agent, set the speed of 2200r / min, stirring time 15min, to give secondary products ;;

[0054] Step C: The product of two cylinders into a grinding, polishing using zirconium beads, milled three times, each time the polishing 30min, to obtain the finished product.

[0055] Said step A comprises: T1: 20 parts by weight of an inorganic resin and 60 parts by weig...

Embodiment 3

[0057] like figure 1 Shown, a novel method for preparing a modified inorganic hybrid of acrylic coatings, comprising the steps of:

[0058] Step A: 17 parts by weight of the inorganic parts by weight of resin and acrylic resin 50 is poured into the production of the cylinder, the rotational speed is set to 2000r / min, the stirring time to 12min, then poured into a sealed can was subjected to ultrasonic dispersion time is set to 17min , to give a product;

[0059] Step B: To the product of the production of a cylinder, 5 parts by weight of the solvent, 25 parts by weight of pigment and 0.7 parts by weight of an antifoaming agent, set the speed of 2000r / min, 12min stirring time, to give two products;

[0060] Step C: The product of two cylinders into a grinding, polishing using zirconium beads, milled three times, each time the polishing 22min, to obtain the finished product.

[0061] Said step A comprises: T1: 17 parts by weight of an inorganic resin by weight and 50 parts acryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com