A kind of engine cylinder head and preparation method thereof

An engine cylinder head and air-cooled technology, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the thermal conductivity of vermicular iron, limit the lightweight design space of vermicular graphite cast iron cylinder head, thermal fatigue of vermicular graphite cast iron cylinder head Low service life and other problems, to achieve the effect of improving thermal fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

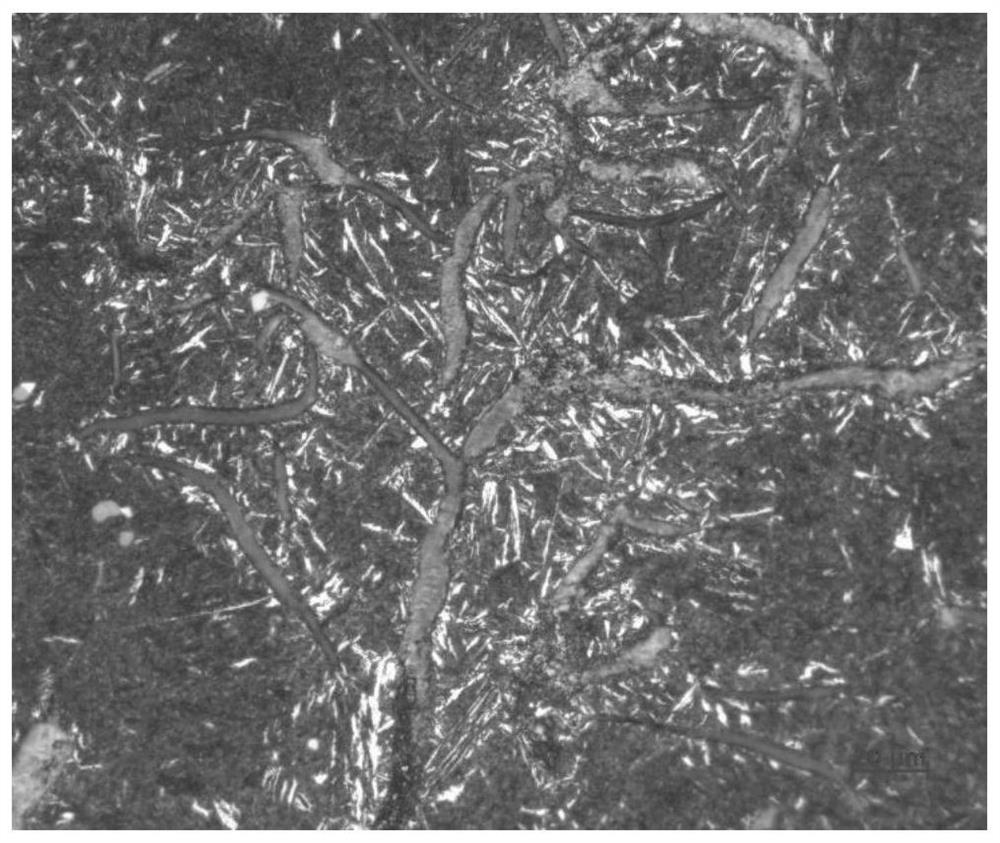

[0032] A kind of preparation method of engine cylinder head that the embodiment of the present application provides, it comprises the following steps:

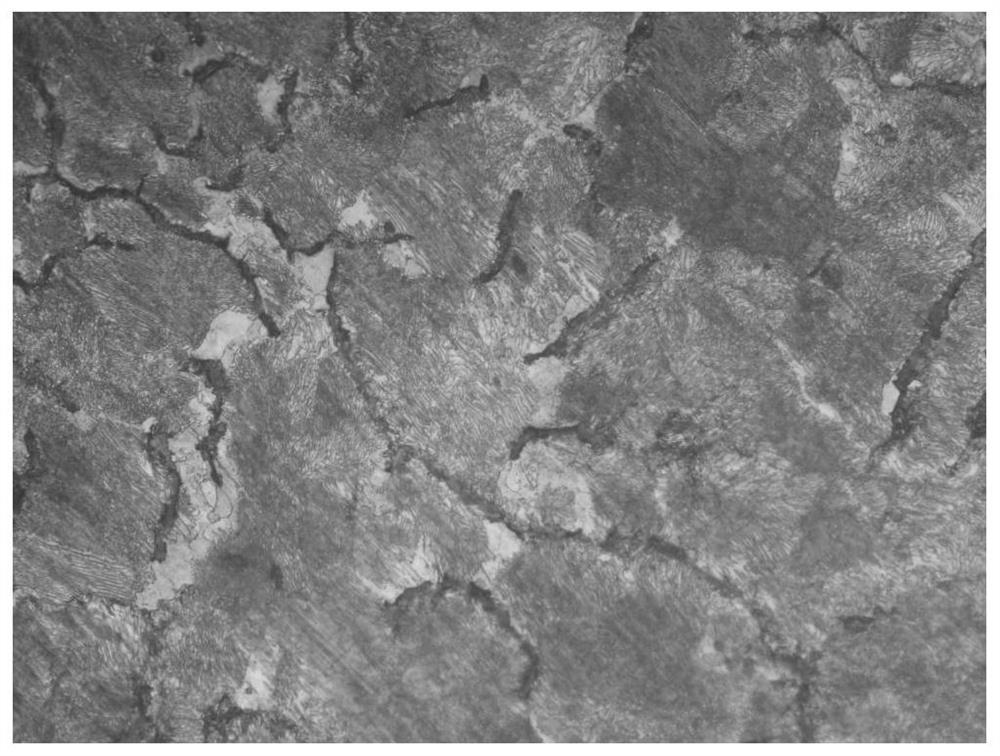

[0033] (1) Normalizing treatment: heat the engine cylinder head blank cast by alloy material to 850℃~950℃, and keep it warm for 1.5h~2.5h; then carry out air cooling, stop air cooling after cooling to ≤230℃, and finally Cool to room temperature;

[0034] (2) Tempering treatment: put the normalized engine cylinder head blank into the furnace for tempering treatment, the tempering temperature is 550℃~650℃, and the tempering time is 2~3h;

[0035] (3) After the tempering treatment is completed, shot peening and machining are performed in sequence to obtain the engine cylinder head.

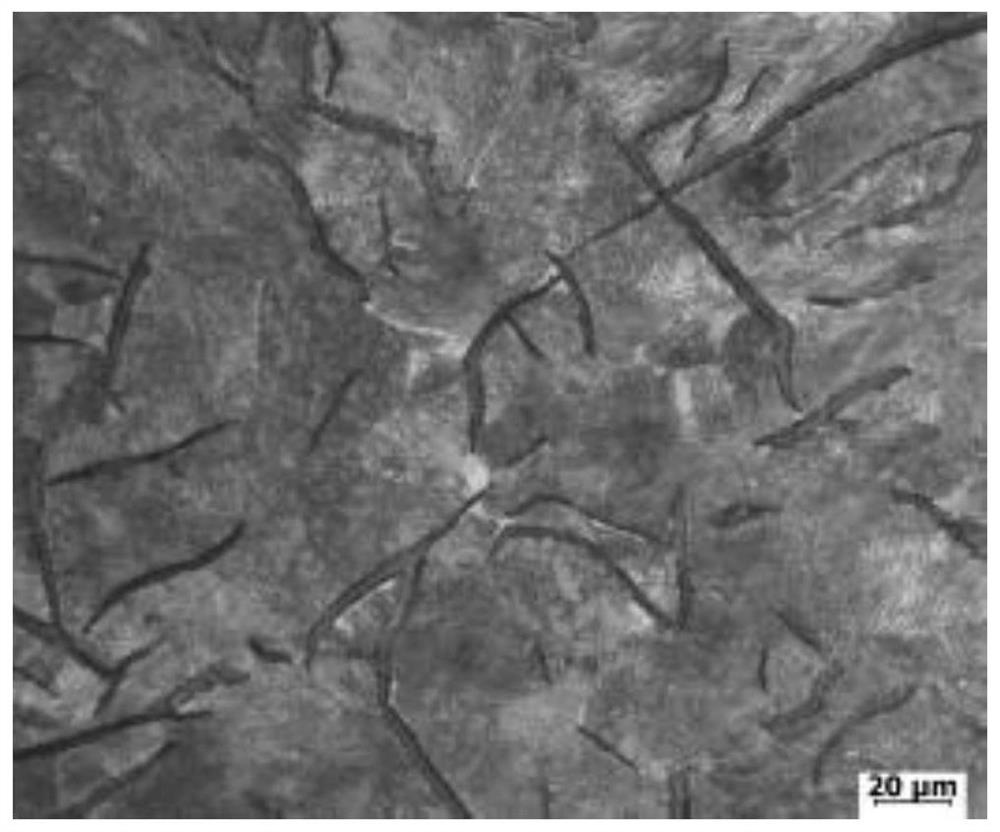

[0036] In step (1), the alloy material can be HT300 or RuT450. If the holding temperature is lower than 850°C, or the holding time is lower than 1.5 hours, the engine cylinder head blank cannot be fully austenitized, which will affect the final nor...

Embodiment 1

[0043] A kind of preparation method of engine cylinder head that present embodiment provides, it comprises the following steps:

[0044] Step 1) Material selection: According to the requirements of the national standard GB / T 9439-2010, the common alloy gray iron HT300 material is selected.

[0045] Step 2) Casting: the raw materials are melted and then cast, and the required HT300 engine cylinder head blank is cast.

[0046]Step 3) Normalizing treatment: Put the cast HT300 engine cylinder head blank into a common heating furnace and heat it to 850°C, keep it warm for 2 hours, and then quickly air cool it after it comes out of the furnace, and the air cooling speed is 45°C / min. In order to ensure the cooling uniformity of the cylinder head, the fire surface and the back of the HT300 engine cylinder head blank are simultaneously blown and cooled. After cooling to 230°C, the air cooling is stopped and placed in the air to cool to room temperature.

[0047] Step 4) Tempering trea...

Embodiment 2

[0052] A kind of preparation method of engine cylinder head that present embodiment provides, it comprises the following steps:

[0053] Step 1) Material selection: According to the requirements of the national standard GB / T 9439-2010, the common alloy gray iron HT300 material is selected.

[0054] Step 2) Casting: the raw materials are melted and then cast, and the required HT300 engine cylinder head blank is cast.

[0055] Step 3) Normalizing treatment: Put the cast HT300 engine cylinder head blank into a common heating furnace and heat it to 870°C, keep it warm for 2 hours, and then quickly air-cool it after it comes out of the furnace, and the air-cooling speed is 75°C / min. In order to ensure the cooling uniformity of the cylinder head, the fire surface and the back of the HT300 engine cylinder head blank are simultaneously blown and cooled. After cooling to 230°C, the air cooling is stopped and placed in the air to cool to room temperature.

[0056] Step 4) Tempering tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com